DIN 1.2714/56nicrmov7  ASTM 6f3 GB 5crnimov  Alloy Forged Block Mould Steel

HUNAN QILU INDUSTRIAL CO., LTD.- Type:Carbon Steel Bar

- Standard:AISI, ASTM, DIN, JIS, GB, BS

- Technique:Forged

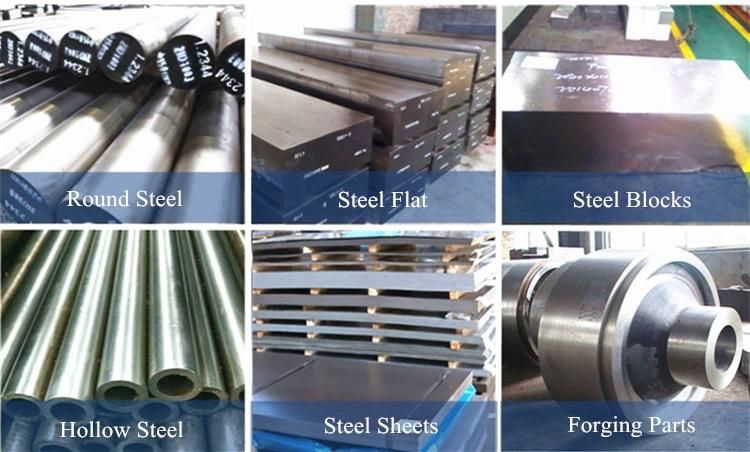

- Shape:Round Bars, Flat Bar , Blocks, Tube

- Surface Treatment:Black; Peeled; Polished; Machined; Grinded; Turned

- Special Use:Cold Heading Steel, Free Cutting Steel, Mold Steel

Base Info

- Model NO.:1.2714

- Model No.:GB 5CrNiMo JIS Skt4 DIN 1.2713 ASTM L6,T61206 BS B

- Factory:Yes

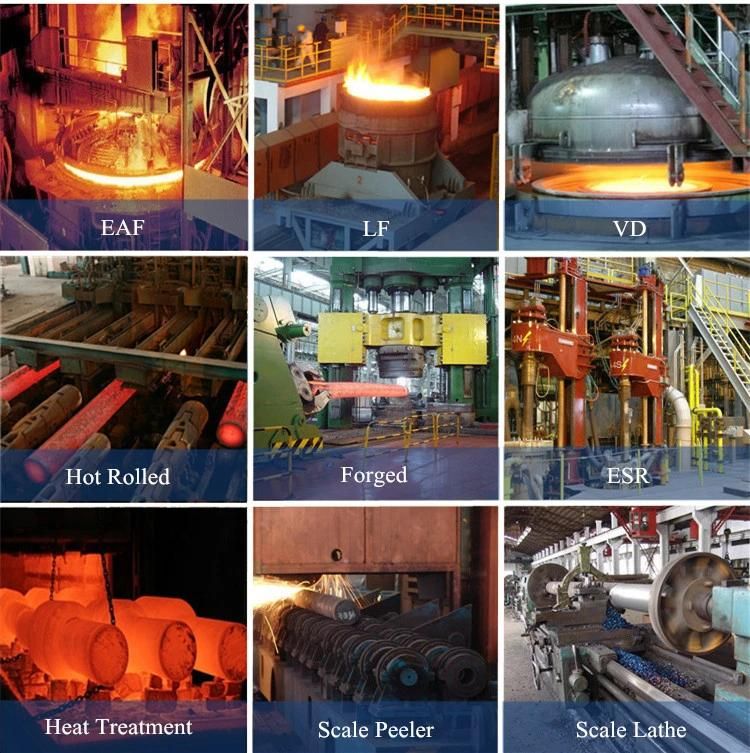

- Process:Eaf+Lf+Vd+Forged+Heat Treatment(Optional)

- Technology:Hot Rolled, Forged, Cold Drawn

- Heat Treatment:Normalized;Annealed ;Quenched ;Tempered

- Surface:Black; Peeled; Polished; Machined; Grinded; Turned

- Test:Ensile Strength, Yield Strength, Elongation,

- Certificate:ISO, Mill Certificate

- Experience:15 Years Manufacturer Experience

- Usage:Automotive, Aerospace, Power Generation, Oil & Gas

- Service:24 Hours on Line

- Other Type 1:Engineering Steel, Cold Work Tool Steel

- Other Type 2:Hot Work Tool Steel, Plastic Mold Steel,

- Other Type 3:Spring Steel, High Speed Steel, Stainless Steel ,

- Other Type 4:Mold Steel, Free Cutting Steel, Cold Heading Steel

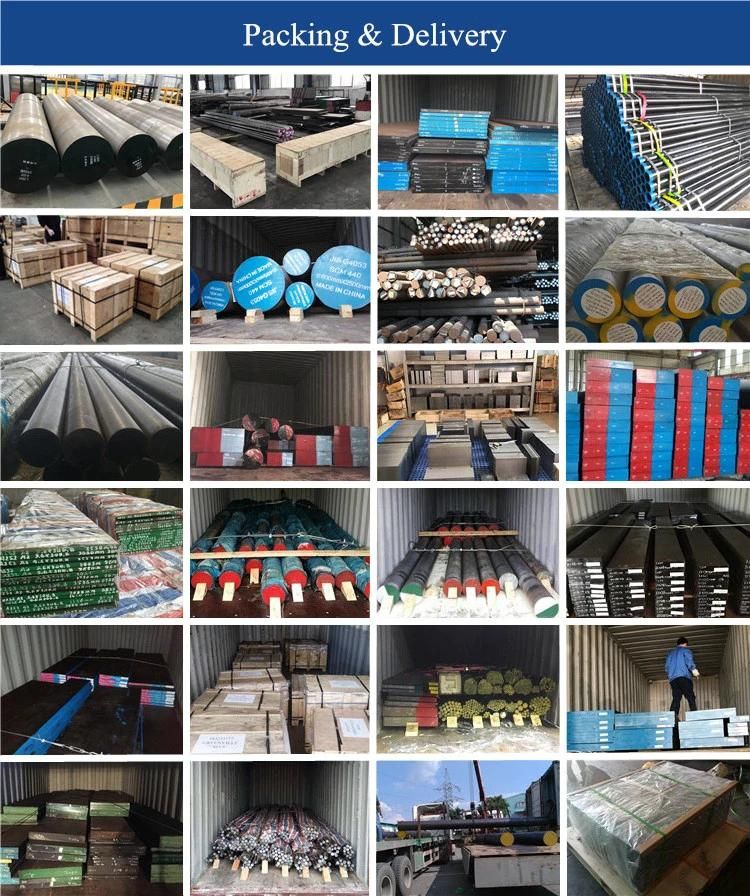

- Transport Package:Standard Packages, or as Customers Request

- Specification:ISO 9001-2000

- Trademark:QILU

- Origin:China Shangdong

- HS Code:72284000

- Production Capacity:500, 000tons,Year

Description

6: Heat treatment

The preheating of measuring and cutting tool steel is spheroidizing annealing, final heat treatment is quenching + low temperature tempering and hardness after heat treatment can reach 60~65HRC. When heat treat tool steel grades consideration should be given to hardening temperature, including ratio of heating, cooling and soaking times which will differ due to factors such as the shape and size of each chemical component. Other considerations during heat treatment include the type of furnace, quenching medium and work piece transfer facilities.

7: Features and classificationsHot-work die divides into several main types, such as hammer forging, die forging, extrusion and die casting, including hot forging die, press machine forging die, stamping die, hot-extrusion die, metal die-casting mould. Heat distortion mould not only supports huge mechanical stress, but also thermal stress during working repeatedly. Hot-work die steel should have not only high hardness, red hardness, abrasion resistance, toughness, but also have excellent high temperature strength, thermal fatigue stability, thermal conductivity, upper harden-ability for guaranteeing the whole cross section with consistent mechanical property.

8: Delivery conditionFor hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

Hunan Qilu Industrial Co., Ltd has the capacity to forge round steel, steel flat, square steel, module, shaft and roller, etc. The main specifications of the products include Φ80-1000mm forging materials and 80-1200mm square billets and which the maximum piece weight can reach 50T.

Hunan Qilu Industrial Co., Ltd were already engaged in exporting steel for 11 years, could supply a great variety of hot forged, hot rolled and cold drawn Steels, including engineering steel, cold work tool steel, hot work tool steel, plastic mold steel, spring steel, high speed steel, stainless steel etc., besides Qilu Industrial also has their own heating treatment shop and machining shop to provide heating and cutting service.

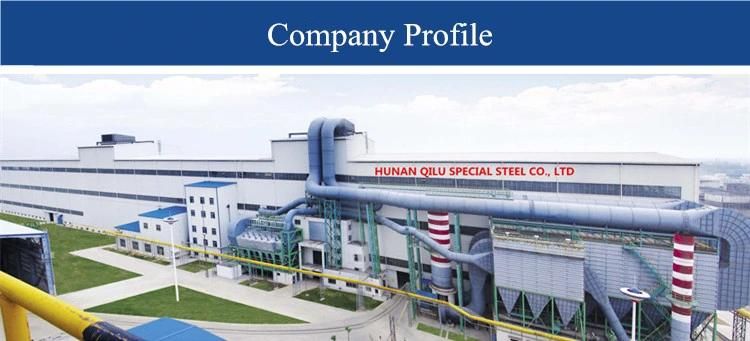

Since 2008 year, Hunan Qilu Industrial has the right to export all FORGED STEEL behalf of Qilu Speical Steel Co.,ltd which is specialized in smelting and forging of special steel since 1965 year, now Qilu special steel is one of the biggest manufacturer of forged product in China.The forged products are used in Automotive, Aerospace, Power Generation, Oil & Gas, Transportation and Industrial. We already set up the warehouse in Wuxi and Dongguan city, more than 20000 tons ex-stock could be supplied with kinds of size.

Qilu Industrial is the professional one-stop steel manufacturer, stockist and exporter in China, our customers spread all over the world, include West Europe, North America, South America, Asia, Middle Asia, Africa, Australia, etc.

The company owns advanced special steel smelting facilities and forging processing equipments, the main steel-making equipment include 2 sets of 50t ultra-high power electric arc furnaces,2 sets of 60t LF refining furnaces,1 set of 60t vacuum degassing refining furnace and 4 sets of 1-20t electroslag re-melting furnaces.

The main forging equipments mainly include:3 sets of 5t electro-hydraulic hammers, 1 set of high-speed forging units of 800t,1600t,2000t and 4500t respectively.

Mier Lu

Hunan Qilu Industrial CO., LTD

Website: qilusteel.en.made-in-china.com

Tel: 86-731-85185769

Fax: 86-0731-85185771

Mobile/ : +86 1893241249