1.2379 Alloy Steel Plate For Cold Work Mould Steel

Guangzhou Changfeng Steel Co., Ltd.- Technique:Hot Rolled

- Standard:AISI, JIS, ASTM, DIN, BS, GB

- Grade:(D2,1.2379,SKD11)

- Certificate:ISO , Mill Certificate

- Test:SGS , Ut 100% , Element Testing

- Payment:30% Deposit,Blance by L,C at Sight or T,T

Base Info

- Model NO.:1.2379,D2,SKD11,Cr12Mo1V1

- Hardness (HRC):60-65HRC

- Delivery Quantity:Include MOQ

- Transport Package:Standard Packing

- Specification:20-500mm

- Trademark:CF STEEL

- Origin:China

- HS Code:7225

- Production Capacity:1000t,Month

Description

Hardness

(HRC)First preheating Second preheating Last heating 600-650 800-850 1020-1040 Air Cooling 61-63 500-560 2 ≥58 Introduction

Application:

1) used for freezer compressor rear cowl mould quenching hardening 56~58HRC.

2) because of V,Mo composition are higher than Cr12MoV steel, so that it has better combination property and will instead of Cr12MoVsteel gradually.

3) making cylindrical die roll,destage mixing pad cold punching mould and the service life is5-6 times longer than Cr12MoV steel.

Feature

1. High high wear resistant,

2. micro deformation

3. Long service life

4. Good toughness

5. high accuracy, high efficiency, varieties

Delivery days:

For abundant stock, 15-20 days.

For customized products, 30-50 days.

Package: We provide standard export packing or according to customers' request

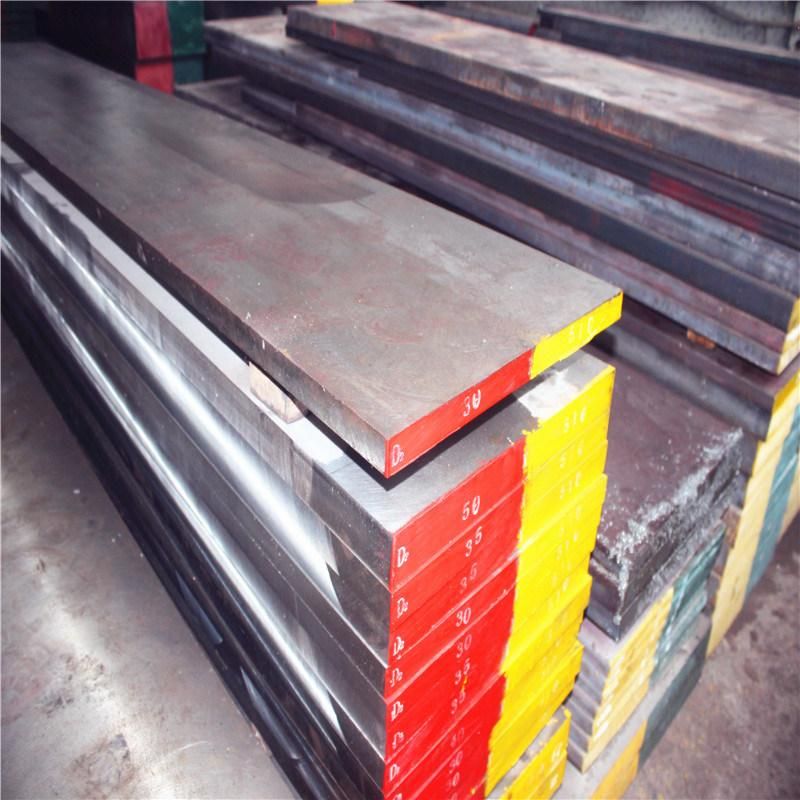

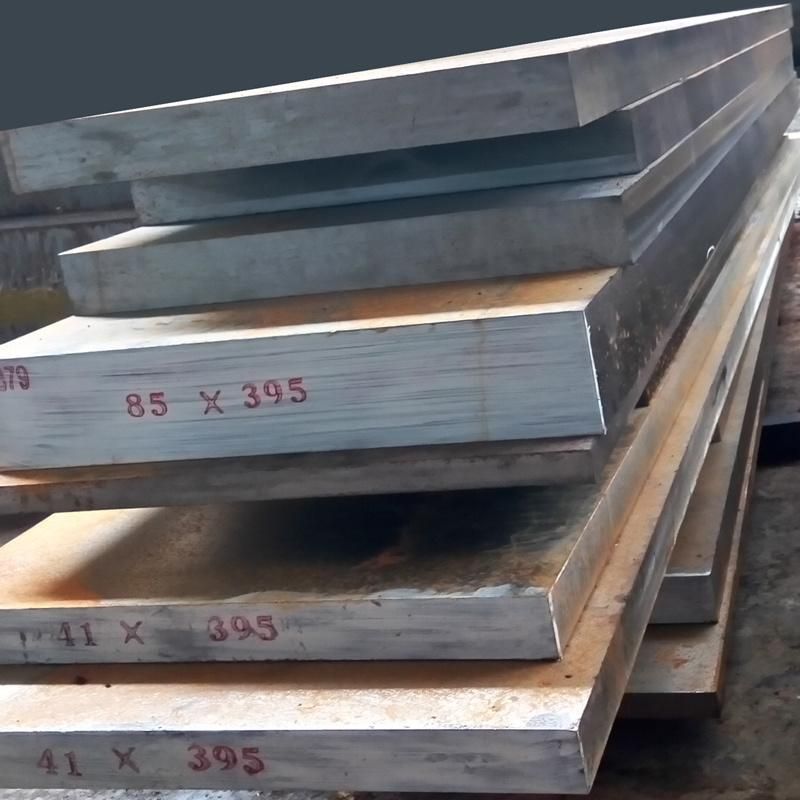

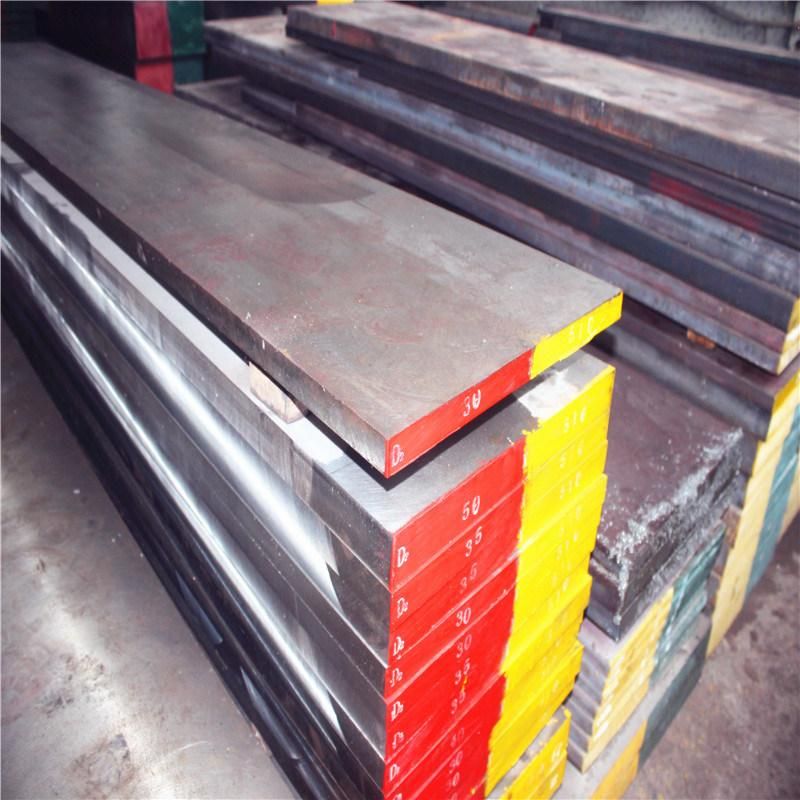

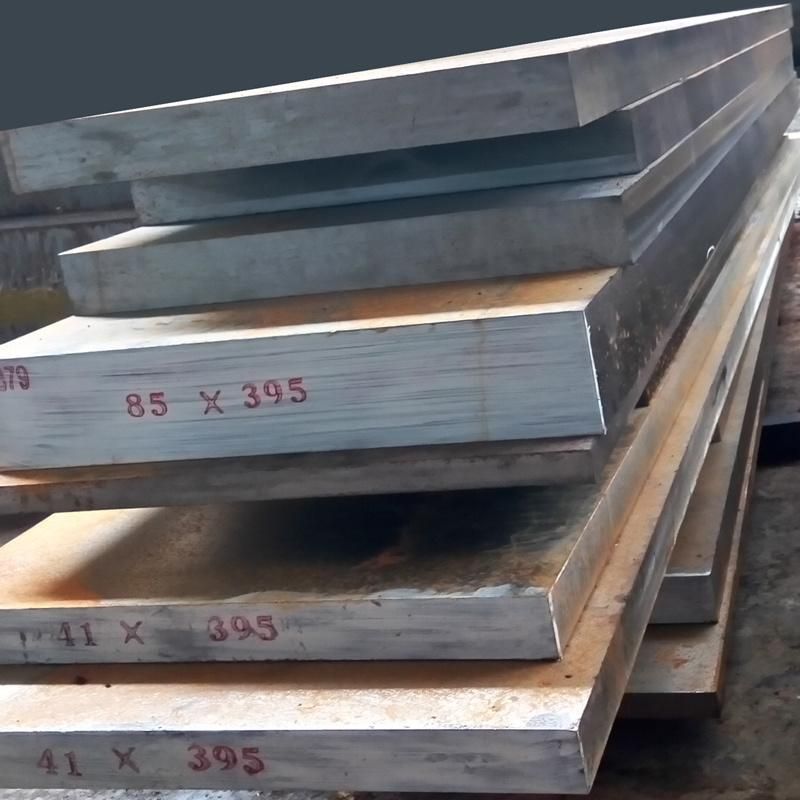

Products show:

Loading container:

(HRC)

Introduction

D2 steel is a high wear resistant micro deformation cold working die steel, belonging to air hardening tool steel. With high quality fraction of carbon and high chronic, the hardness can up to 60HRC after heat treatment, but malleability,toughness,rust resistance is not good and the surface of the steel is also difficult to be polished.

With the development of cold stamping products moving towards high accuracy,high efficiency,varieties, we require the mould steel should has good wear resistance and high toughness.

Compared with Cr12MoV steel, this D2 die steel adds Mo,V compositions,changed the steel cast structure, improved the morphology of ledeburite , toughness and wear resistance are better than Cr12MoV steel, improved the service life as well.Because of the yield point and plastic deformation resistance is higher than Cr12MoV steel, so that forging performance and hot molding properties are a little weak than Cr12MoV steel.

Application:

1) used for freezer compressor rear cowl mould quenching hardening 56~58HRC.

2) because of V,Mo composition are higher than Cr12MoV steel, so that it has better combination property and will instead of Cr12MoVsteel gradually.

3) making cylindrical die roll,destage mixing pad cold punching mould and the service life is5-6 times longer than Cr12MoV steel.

Feature

1. High high wear resistant,

2. micro deformation

3. Long service life

4. Good toughness

5. high accuracy, high efficiency, varieties

Delivery days:

For abundant stock, 15-20 days.

For customized products, 30-50 days.

Package: We provide standard export packing or according to customers' request

Products show:

Loading container: