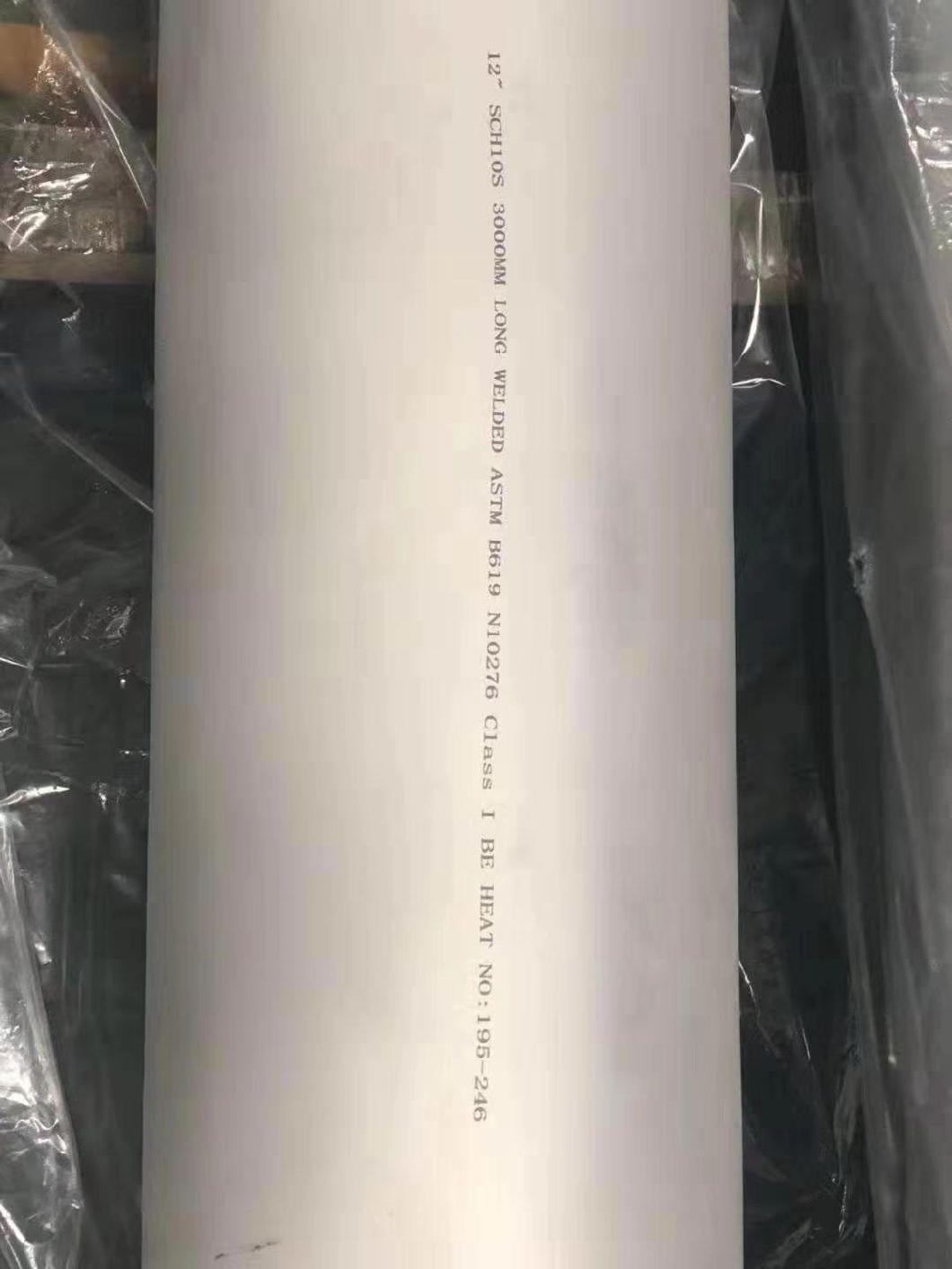

Hastelloy C-276 ASTM B619 N10276 Welded Steel Pipes

Guangzhou Kingmetal Steel Industry Co., Ltd.- Type:Welded

- Technique:Cold Drawn

- Material:Alloy Steel

- Usage:Boiler Pipe, Oil,Gas Drilling, Chemical Industry, Mining

- Section Shape:Round

- Thickness:0.5 - 18 mm

Base Info

- Model NO.:EYWP

- Length:1-12m

- Secondary or Not:Non-Secondary

- Standard or Not:Standard

- Alloy or Not:Alloy

- Delivery Time:15-30 Days Ex Mill

- Transport Package:Export Standard Package

- Specification:6 - 219 mm

- Trademark:Kingmetal

- Origin:China (Mainland)

- Production Capacity:1000 Tons Per Month

Description

SAW/ ERW/ EFW Pipe & Tube

Technique

Standard

UNS N02200/Ni 200,

UNS N02201 /Ni201,

UNS N04400/ Monel 400,

UNS N06002 /Hastelloy X,

UNS N06022/ Hastelloy C22,

UNS N08825/ Incoloy 825,

UNS N10276/ Hastelloy C276,

UNS N10665 /Hastelloy B2,

UNS N10675/Hastelloy B3,

UNS N06600/Inconel 600,

UNS N06601/ Inconel 601,

UNS N06625 /Inconel 625,

UNS N08020 /Alloy 20

UNS N02200/Ni 200,

UNS N02201 /Ni201

UNS N02200/Ni 200,

UNS N02201 /Ni201,

UNS N06601/ Inconel 601

UNS N04400/ Monel 400,

UNS N06600/Inconel 600,

UNS N08800 /Incoloy 800, UNS N08810 /Incoloy 800H,

UNS N08811 /Incoloy 800HT

UNS N10665/Hastelloy B2, U

NS N10675/Hastelloy B3,

UNS N06200/C2000,

UNS N10276 /C276,

UNS N06002/ Hastelloy-X,

UNS N08031/Alloy 31

TP304,TP304L,TP316,TP316L,316Ti,

TP317, TP317L, TP321, TP310S, TP347,

S31254,N08367,N08926,N08904

TP304,TP304L,TP316,TP316L,316Ti TP317,

TP317L,TP321,TP310S,TP347,S31254,

N08367, N08926,N08904

TP304,TP304L,TP316,TP316L,TP317,

TP317L,TP321,TP347,

S31254,N08367,N08926

GR.B, X42, X46, X52, X56, X60,

X65, X70 PSL1 & PSL2

Hastelloy C-276 (UNS N10276) has excellent resistance to localized corrosion, stress corrosion cracking, and to both oxidizing and reducing media, thus making it suitable for a wide variety of chemical process environments, including ferric and cupric chlorides, hot contaminated media (organic and inorganic), formic and acetic acids, seawater and brine solutions. It is one of the few materials that withstands the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide.

Applications: Chemical processing, waste treatment, pollution control, pulp and paper production, and marine engineering.