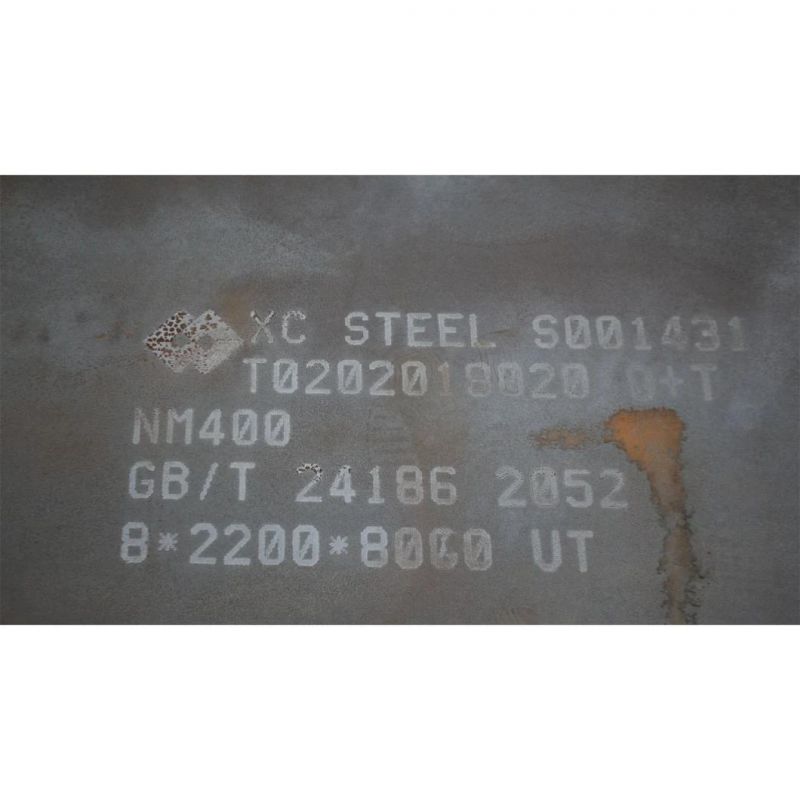

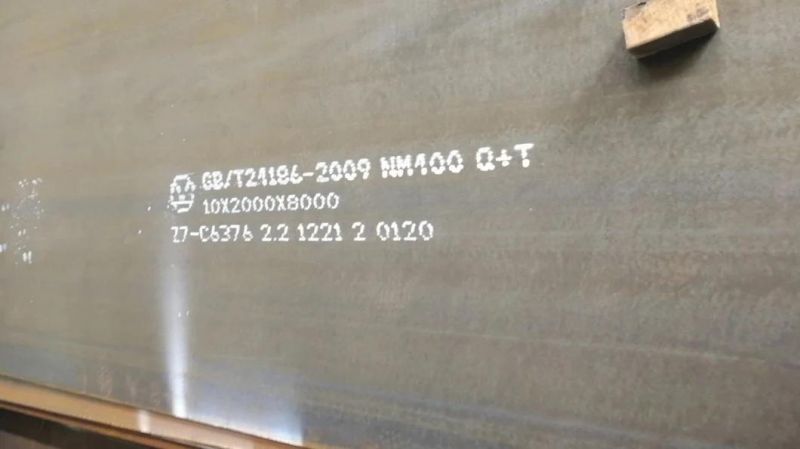

Exetreme Abrasion Steel Sheet Ar Materials High Toughness Steel Sheet 12mmthcikness Length 8inch Width 4inch Steel Sheet

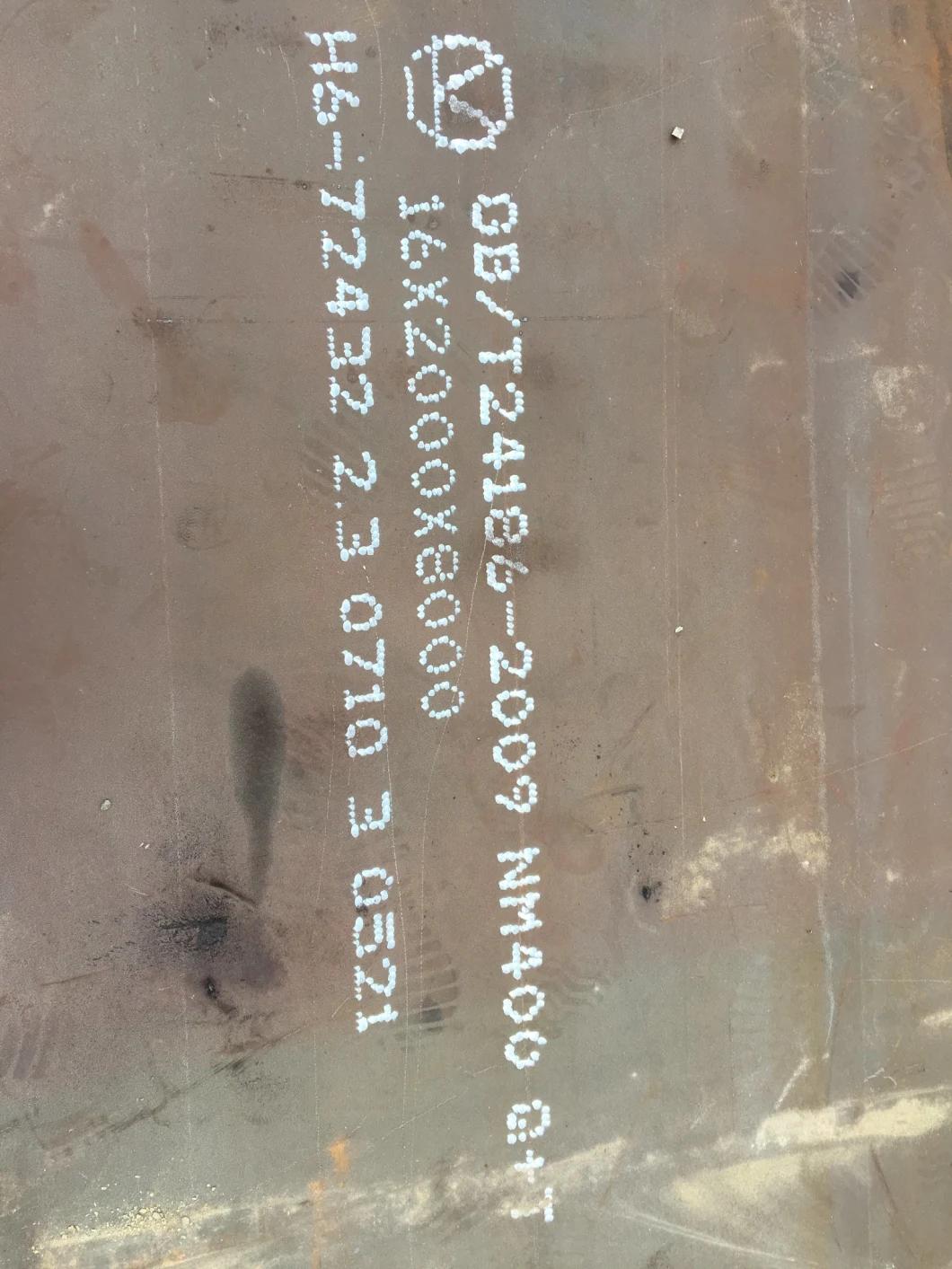

Wuxi Hengchengtai Special Steel Co., Ltd.- Type:Steel Plate

- Standard:ASTM, AISI, GB

- Certification:ISO, RoHS

- Surface Treatment:Anti Rust Primer

- Technique:Hot Rolled

- Application:Mold & Dies, Ship Plate, Boiler Plate, Container Plate, Flange Plate

Base Info

- Special Use:Cutting Tools, Measuring Tools, Cutters in Common Steel, High-strength Steel Plate, Wear Resistant Steel, Silicon Steel

- Stock:Stock

- Width:1m 1.219m 1.5m 1.8m 2.0m 2.2m

- Length:2.44m 3m 5.8m 6m 9.6m 12m

- Process:Quenched and Tempered Process

- Uses:Mining Machinery and Equipment,Grinder Equipment

- Hardness:360-550HBV

- Tensile Strength:900MPa

- Yield Strength:1000MPa

- Testing:Accept Third Party Inspection

- Delivery Time:7-15days After Confirming Order

- Deliver Status:Tempered Quenched

- MOQ:1ton

- Processing Service:Bending Cutting Welding Punching

- Tolerance:0.2mm

- Transport Package:Waterproof Package

- Specification:4mm 6mm 8mm 12mm 110mm

- Origin:Wuxi, China (Mainland)

- HS Code:7219340000

- Production Capacity:50000tons Per Month

Description

Basic Info.

Special Use Cutting Tools, Measuring Tools, Cutters in Common Steel, High-strength Steel Plate, Wear Resistant Steel, Silicon Steel Stock Stock Width 1m 1.219m 1.5m 1.8m 2.0m 2.2m Length 2.44m 3m 5.8m 6m 9.6m 12m Process Quenched and Tempered Process Uses Mining Machinery and Equipment,Grinder Equipment Hardness 360-550HBV Tensile Strength 900MPa Yield Strength 1000MPa Testing Accept Third Party Inspection Delivery Time 7-15days After Confirming Order Deliver Status Tempered Quenched MOQ 1ton Processing Service Bending Cutting Welding Punching Tolerance 0.2mm Transport Package Waterproof Package Specification 4mm 6mm 8mm 12mm 110mm Origin Wuxi, China (Mainland) HS Code 7219340000 Production Capacity 50000tons Per MonthProduct Description

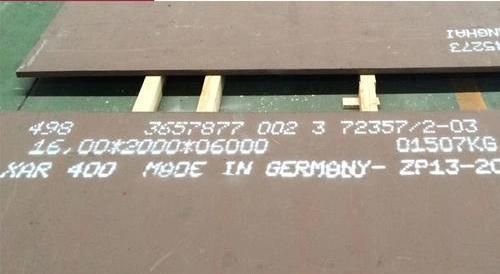

Exetreme abrasion steel sheet AR materials high toughness steel sheet 12mmthcikness length 8inch width 4inch steel sheetHARD600 abrasion resistant steel plate is an abrasion-resistant steel with a nominal hardness of 600 HBW. Hard 600 is a versatile wear-resistant steel. As a result of its high toughness, good bendability and weldability, this steel can be used in structures with moderate wear.

Dimension Range

HARD600 abrasion resistant steel plate is available as plate in thicknesses of 4.0 - 130 mm (5/32 - 5.12"), and as sheet in thicknesses of 2.0 - 8.0 mm (0.079 - 0.315").

HARD600 abrasion resistant steel plate is available in widths up to 3350 mm (131.89") and lengths up to 14630 mm (575.98"). Hard400 sheet is available in widths up to 1650 mm (64.96") and lengths up to 16000 mm (629.92"). More detailed information on dimensions is provided in the dimension program.

Mechanical Properties

1) Brinell hardness, HBW, according to EN ISO 6506-1, on a milled surface 0.5 - 3 mm below surface. At least one test specimen per heat and 40 tons.

The nominal thickness of supplied plates will not deviate more than +/- 15 mm from the thickness of the test specimen used for hardness testing.

HARD600 abrasion resistant steel plate wear resistant steel plate is through-hardened. Minimum core hardness is 90 % of the guaranteed minimum surface hardness.

Impact Properties

Grade

Longitudinal test, typical impact energy,

Hard 400 steel sheet & plate 1)

45 J / -40 oC

Impact toughness measured upon agreement. For thicknesses between 6 - 11.9 mm, sub-size Charpy V-specimens are used. Impact testing according to ISO EN10 148 per heat and thickness group. Average of three tests.

Chemical Composition (heat analysis)

Carbon added during the formation of the steel plate substantially increases toughness and hardness, but reduces strength. Therefore, AR plate is used in situations where abrasions and wear and tear are the main causes of failure. AR plate is not ideal for structural construction uses like support beams in bridges or buildings.

Common uses for AR plate include conveyors, buckets, dump liners, construction attachments, grates, body armor and ballistic plates (and as targets at shooting ranges).

HOW THE QUENCHED & TEMPERED PROCESS CREATES AR PLATE

AR material is produced by quenching and tempering forged steel blocks, or ingots. During this process, the grain structure is changed to increase toughness and encourage formability (or, to be less brittle), and results in through-hardening of the material.

Quenching and tempering (Q&T) is a two-part process:

Quenching occurs when steel brought to a high temperature - usually between 1,500-1,650-degrees Fahrenheit - is rapidly cooled with water. This process causes crystal structures to form within the steel, increasing hardness.

Tempering is the process of re-heating quenched steel to a below-critical temperature (around 300-700-degrees Fahrenheit), and then allowing the plate to cool in normal air temperatures.

Reheating the material breaks down the crystal structures formed during the quenching process, while the long cooling allows the crystal structures to refrom - maintaining most of the strength and hardness, but adding to overall ductility.