ASTM A53 Gr. a Gr. B Carbon Steel Welded Pipe

Guangzhou Kingmetal Steel Industry Co., Ltd.- After-sales Service:Change,Return

- Warranty:10 Year

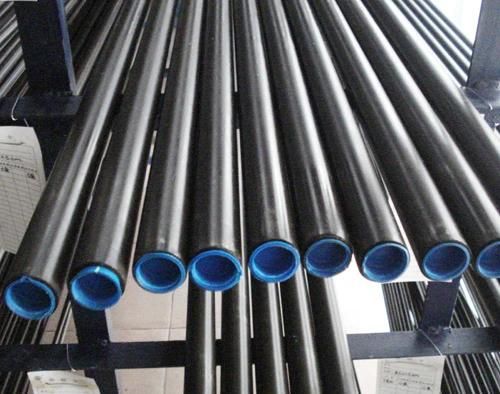

- Type:Welded

- Technique:ERW

- Material:Carbon Steel

- Surface Treatment:Varnishing

Base Info

- Model NO.:DN100

- Usage:Pipeline Transport

- Section Shape:Round

- Length:5.8m,6m,11.8m or Random, or as Request

- Surface:Anti-Corrosion Black Paint, Galvanized

- Transport Package:Seaworthy Export Packing

- Specification:1,8"-26"

- Trademark:KINGMETAL

- Origin:China

- HS Code:730519

- Production Capacity:5000ton,Month

Description

Basic Info.

Model NO. DN100 Usage Pipeline Transport Section Shape Round Length 5.8m,6m,11.8m or Random, or as Request Surface Anti-Corrosion Black Paint, Galvanized Transport Package Seaworthy Export Packing Specification 1/8"-26" Trademark KINGMETAL Origin China HS Code 730519 Production Capacity 5000ton/MonthProduct Description

ASTM A53 Gr.A GR.B Carbon Steel Welded Pipe

ASTM A53 specification covers the steel pipe manufacturing types in seamless and welded, material in carbon steel, black steel. Surface natural, black, and hot-dipped galvanized, zinc coated steel pipe. Diameters range from NPS 1⁄8 to NPS 26 (10.3mm to 660mm), nominal wall thickness.

ASTM A106 standard specification covers the seamless carbon steel pipe, applied for high-temperature services.

For ASTM A53 there are ERW and seamless steel pipes Type F, E, S covers Grade A and B.

A53 Type F, furnace butt welded, continuous weld Grade A

A53 Type E, Electric resistance welded (ERW), in Grade A and Grade B.

A53 Type S, Seamless steel pipe, in Grade A and Grade B.

If raw steel material of different grades in process of continuously casting, the transition material result shall be identified. And the manufacturer should remove the transition material with the processes that could separate the grades positively.

In case ASTM A53 Grade B in ERW (electric resistance welded) pipe, the weld seam shall be done the heat treatment with a minimum 1000°F [540°C]. In this way the no untempered martensite remains.

In case ASTM A53 B pipe in cold expanded, then expansion should not exceed 1.5% of the required OD.

(Please note the type F is not used for flanging, and if type S or type E is applied for coiling or cold bending, it is recommended to use ASTM A106 Grade A pipe. Although, it is not prohibit to use ASTM A106 Grade B for the cold bending and coiling. According the facility from the manufacturer, type E of ASTM A53 pipe could be supplied non cold expanded or cold expand steel pipe.)

ASTM A53 Grade B chemical properties content C≤0.30%, Mn≤1.2%, P≤0.05%, S≤0.045%, Cr≤0.40, Cu≤0.40, Ni≤0.40, Mo≤0.40, V≤0.08.ASTM A53 B mechanical strength is the same with ASTM A106 B steel pipe, Tensile strength maximum 415 Mpa, Yield strength maximum 240 Mpa.

Applications

1. Construction, underground transportation, extraction of ground water while building, steam water transportation etc.

2. Bearing sets, machinery parts processing.

3. Electric application: Gas transmission, water power generation fluid pipeline.

4. Wind power plant anti-static tube etc.

5. Pipelines that required zinc coated.