304 Stainless Steel Slot Pipe

Foshan Hot Chance Metallic Material Co., Ltd.- Type:Welded

- Technique:Cold Rolled

- Material:Stainless Steel

- Surface Treatment:Satin, Mirror, Hairline

- Usage:Pipeline Transport

- Section Shape:Round Square, Rectangular

Base Info

- Model NO.:38.1-76.2mm

- 201ni%:>1%

- 304ni%:>8%

- 316ni%:>10%

- 201c%:<0.1%

- 304c%:<0.08%

- 304L,316L C%:<0.03%

- Diameter:9.5-159mm

- Length:6meter or According to Client′s Request

- Payment:Tt or LC

- Delivery:15-20days

- Transport Package:Seaworthy Packing

- Specification:round: 9.5-259MM, square: 10*10-150*150mm

- Trademark:CHAOJI

- Origin:China

- HS Code:73064000

- Production Capacity:1000tons,Month

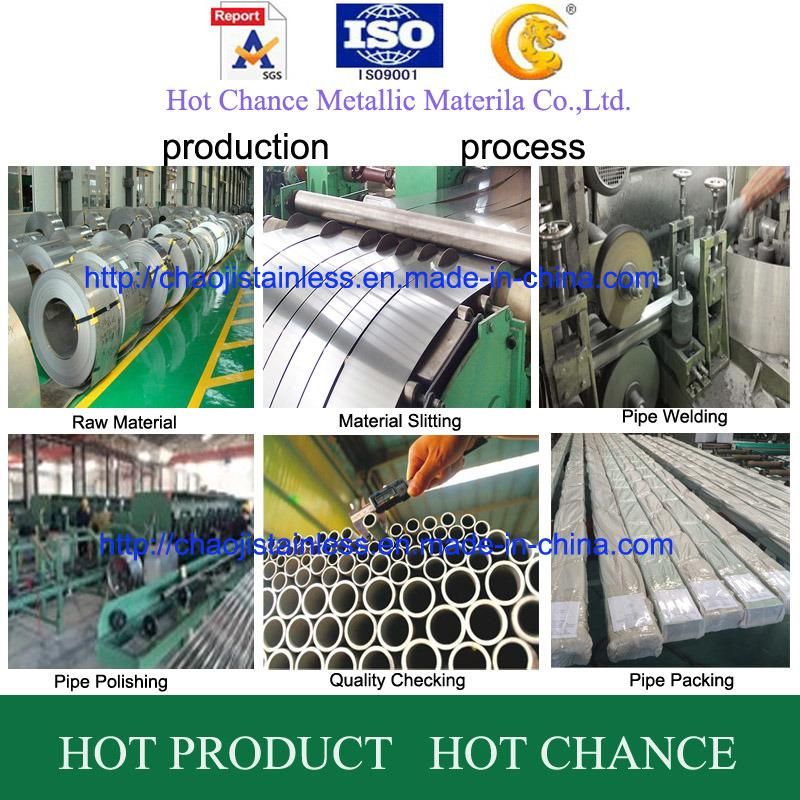

Description

mechanical propertytensile strength ≥535 ≥520 ≥520 ≥520 yield strength ≥245 ≥205 ≥205 ≥205 extension ≥30% ≥30% ≥35% ≥35% hardness (HV) <105 <100 <90 <90

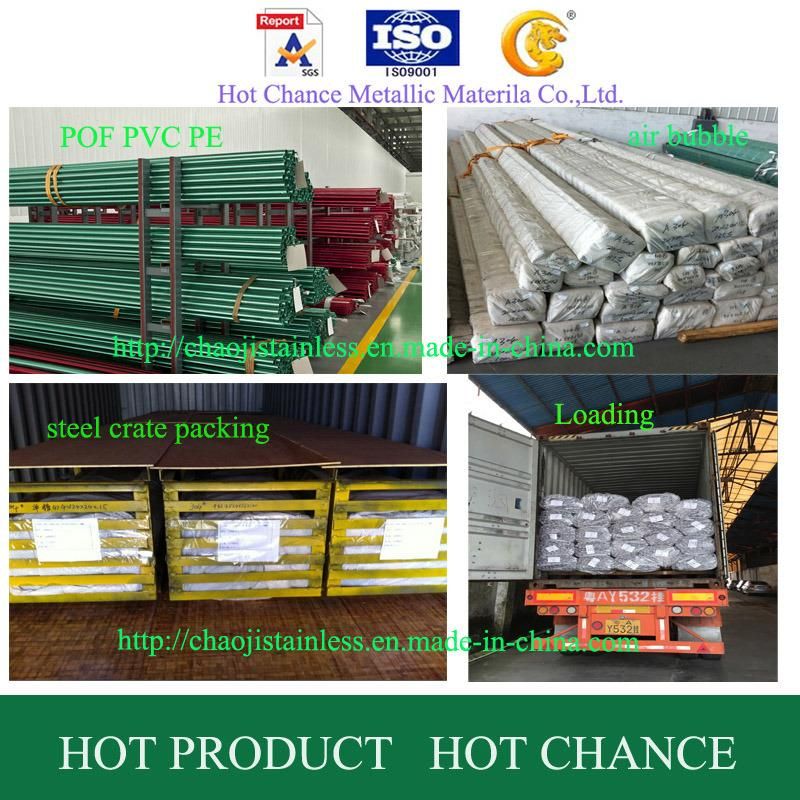

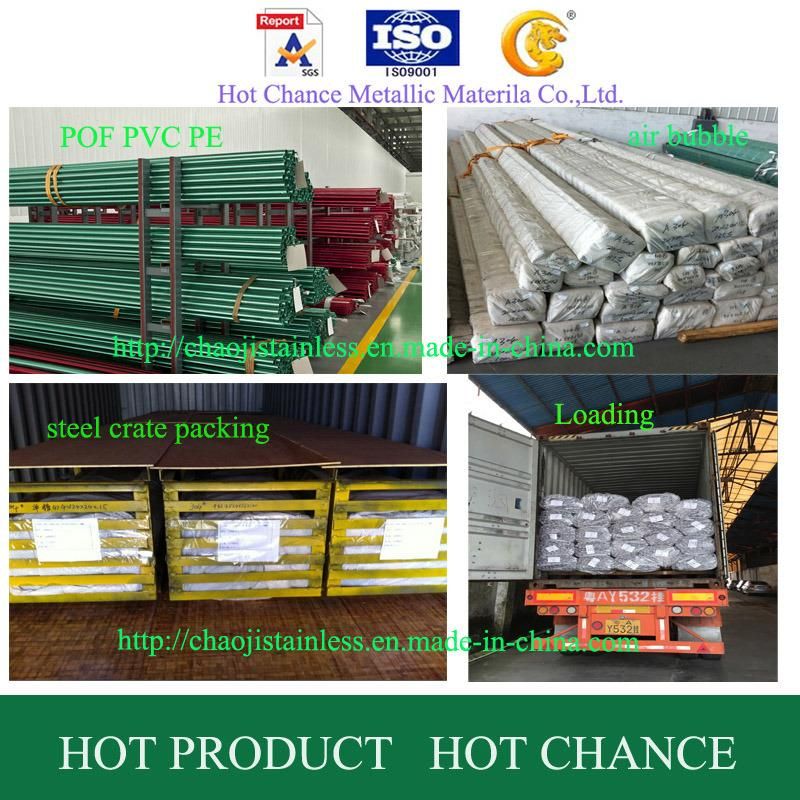

about packing:----------------------

packaging is one of the best service of our company, in order to prevent the damage from transit, our finished products are packaged carefully.

outer packing1)woven packing (standard woven packed for each bundle, around 50-500kgs per bundle

2)as customers' request) iron box ( strong iron box ,each box can load about 1000kg)

about delivery time and shipment:-----------------------

we have plenty of stock in warehouses with abundant capital.

so if you can confirm order soon

we can dispatch goods within 1-30day

our services:-------------------------

1. we are the specialized supplier of stainless steel materials, can provide the best price!

2. we have more than 14 years experience in exporting products to worldwide countries, can provide the high quality products!

3. we have plenty of stock in warehouses with abundant capital.

4. wide excellent experiences with after-sale service.

5. every process will be checked by responsible QC which insures every product's quality.

6. professional packing teams which keep every packing safely.

7. trial order can be done in two week.

8. samples can be provided as your requirements.

FAQ

1. What is your major market?

90% of our tubes are exported . We mainly sell to Southeast Asia, Europe and Australia

We sell to the countries like Thailand ,India,Vietnam ,Indonesia ,Malaysia ,German,Poland, Italy,Australia.

2. What is your location?

We are located in Foshan City which is a famous stainless steel production base.

Our new workshop is located in Sanshui District, Foshan City.

3.What's the annual output?

We produce more than 25000 tons stainless steel tubes in a year.

4. What is your welding method?

All of our tubes are welded by tig welding methods. Our tubes can get fully welding and smooth inner welding, without blisters, leak welding or black line. All of our tube are good for tube bending.

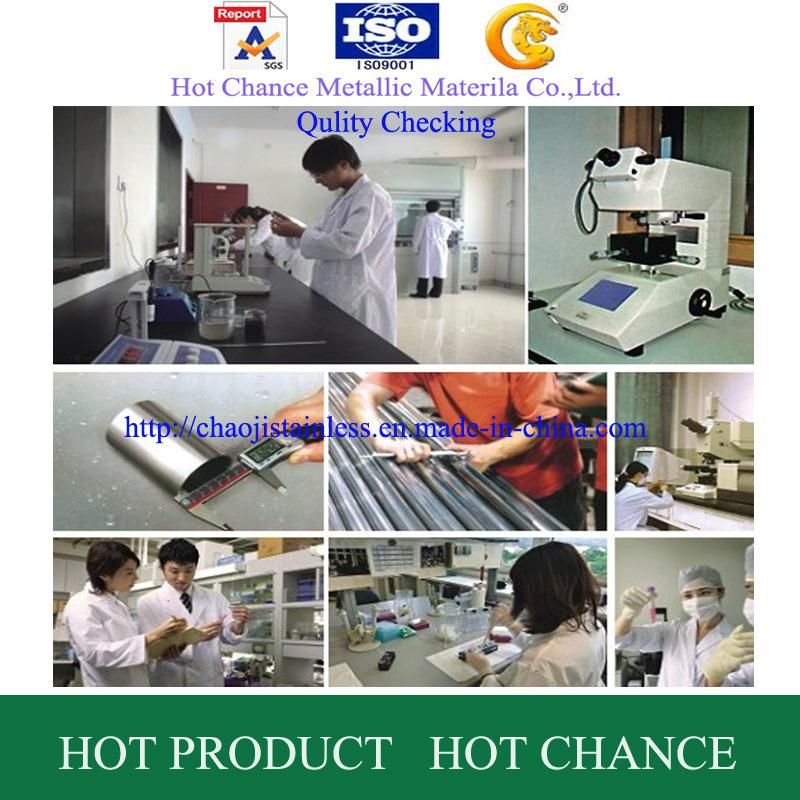

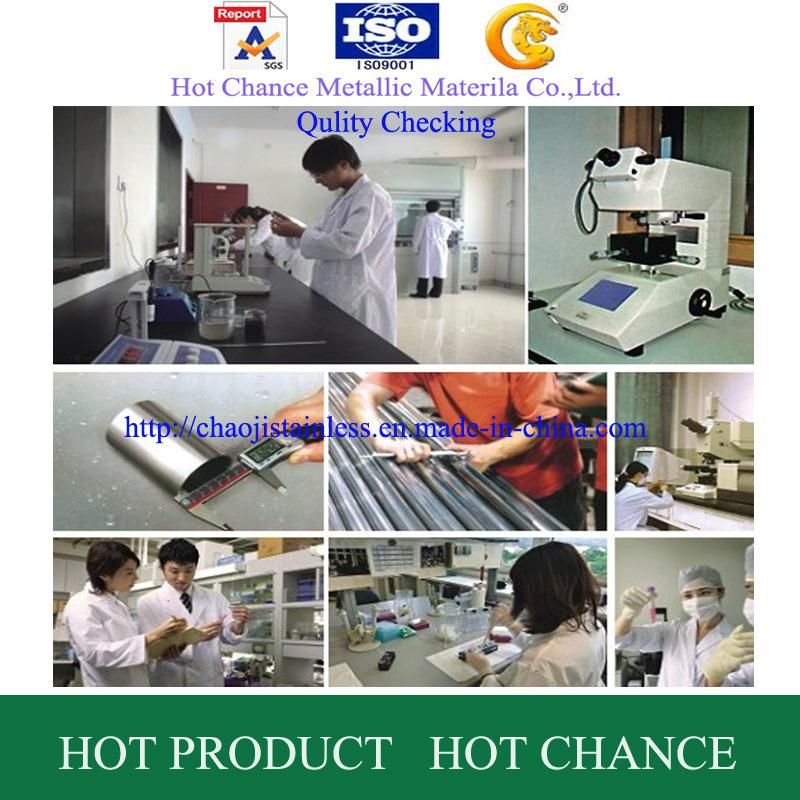

5. How do you control the quality during the polishing process?

1)As for the mirror polish square/rectangular tube , we will polish it as least four times)

2)During the polishing processing, we set a special sanding wheel to polish the welding part.

3)To avoid scratches,after polishing,the tubes will be lay out on a steel crate then we could lift the whole steel crate instead of the tube.

4)On the other hand, we use the gunny bags to protect the tube's surface when the tube laying-out.

6. How do you inspect the tubes?

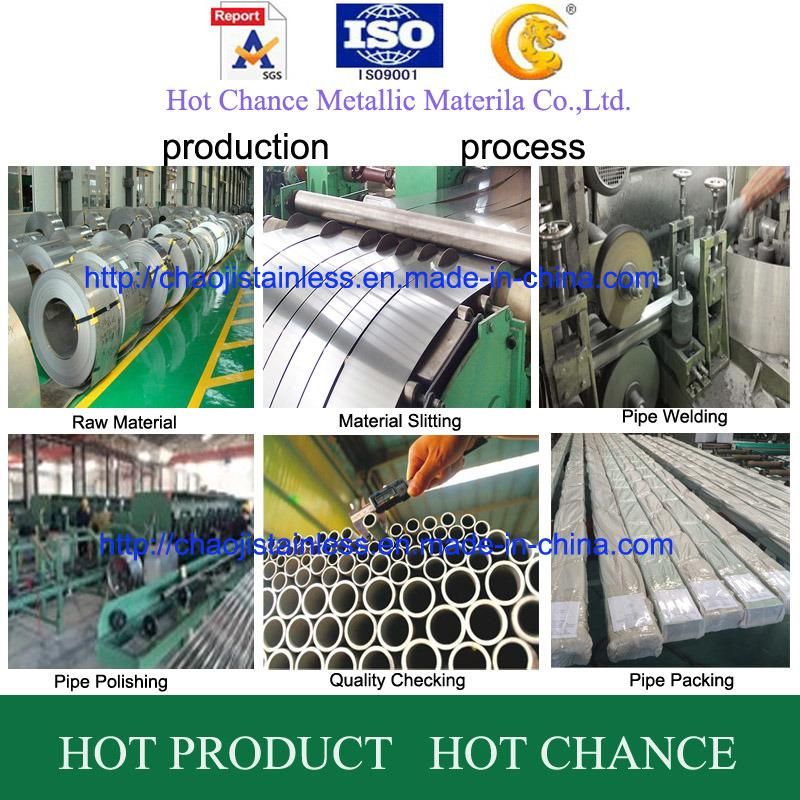

The Quality inspectors inspect the tubes during each production processes from raw material,tube welding,polishing,packaging.

1) Before the production of each machine, we will have the first checked and record the data.

2). During the production, our inspector and engineer have been carefully moniting and we record the data every two hours.

CONTACT INFORMATION--------------------

Sandy (Sales)

about packing:----------------------

packaging is one of the best service of our company, in order to prevent the damage from transit, our finished products are packaged carefully.

outer packing

2)as customers' request)

about delivery time and shipment:-----------------------

we have plenty of stock in warehouses with abundant capital.

so if you can confirm order soon

we can dispatch goods within 1-30day

our services:-------------------------

1. we are the specialized supplier of stainless steel materials, can provide the best price!

2. we have more than 14 years experience in exporting products to worldwide countries, can provide the high quality products!

3. we have plenty of stock in warehouses with abundant capital.

4. wide excellent experiences with after-sale service.

5. every process will be checked by responsible QC which insures every product's quality.

6. professional packing teams which keep every packing safely.

7. trial order can be done in two week.

8. samples can be provided as your requirements.

| Product Name | Diameter Specification(mm) | thickness(mm) | Note |

| Round pipe | 9.53 | 0.5-1.1 | |

| Round pipe | 10 | 0.5-1.1 | |

| Round pipe | 12 | 0.5-1.1 | |

| Round pipe | 12.7 | 0.5-1.1 | |

| Round pipe | 15.9 | 0.5-1.5 | |

| Round pipe | 19.05 | 0.5-1.5 | |

| Round pipe | 22.2 | 0.5-1.5 | |

| Round pipe | 25.4 | 0.5-1.9 | |

| Round pipe | 31.8 | 1.0-2.0 | |

| Round pipe | 38.1 | 1.0-2.0 | |

| Round pipe | 42.4 | 1.0-2.0 | |

| Round pipe | 48.3 | 1.0-2.0 | |

| Round pipe | 50.8 | 1.0-2.5 | |

| Round pipe | 57 | 1.0-2.5 | |

| Round pipe | 60.3 | 1.0-2.5 | |

| Round pipe | 63.5 | 1.0-3.0 | |

| Round pipe | 76.2 | 1.0-3.0 | |

| Round pipe | 88.9 | 1.0-3.0 | |

| Round pipe | 101.6 | 1.0-3.0 | |

| Round pipe | 114 | 1.0-3.0 | |

| Round pipe | 127 | 1.0-3.0 | |

| Round pipe | 133 | 1.0-3.0 | |

| Round pipe | 159 | 1.0-3.0 | |

| Round pipe | 168 | 1.0-3.0 | |

| Round pipe | 219 | 1.0-3.0 |

| Product Name | Specification(mm) | thickness(mm) | Note |

| square pipe | 10×10 | 0.5-1.1 | |

| square pipe | 12.7×12.7 | 0.5-1.1 | |

| square pipe | 15×15 | 0.5-1.1 | |

| square pipe | 19×19 | 0.5-1.5 | |

| square pipe | 20×20 | 0.5-1.5 | |

| square pipe | 22×22 | 0.5-1.5 | |

| square pipe | 25×25 | 0.5-1.9 | |

| square pipe | 30×30 | 1.0-2.0 | |

| square pipe | 38×38 | 1.0-2.5 | |

| square pipe | 40×40 | 1.0-2.5 | |

| square pipe | 50×50 | 1.0-2.5 | |

| square pipe | 60×60 | 1.0-2.5 | |

| square pipe | 75×75 | 1.0-3.0 | |

| square pipe | 80×80 | 1.0-3.0 | |

| square pipe | 100×100 | 1.0-3.0 | |

| square pipe | 150×150 | 1.0-3.0 | |

| Product Name | Specification(mm) | thickness(mm) | Note |

| square pipe | 10×10 | 0.5-1.1 | |

| square pipe | 12.7×12.7 | 0.5-1.1 | |

| square pipe | 15×15 | 0.5-1.1 | |

| square pipe | 19×19 | 0.5-1.5 | |

| square pipe | 20×20 | 0.5-1.5 | |

| square pipe | 22×22 | 0.5-1.5 | |

| square pipe | 25×25 | 0.5-1.9 | |

| square pipe | 30×30 | 1.0-2.0 | |

| square pipe | 38×38 | 1.0-2.5 | |

| square pipe | 40×40 | 1.0-2.5 | |

| square pipe | 50×50 | 1.0-2.5 | |

| square pipe | 60×60 | 1.0-2.5 | |

| square pipe | 75×75 | 1.0-3.0 | |

| square pipe | 80×80 | 1.0-3.0 | |

| square pipe | 100×100 | 1.0-3.0 | |

| square pipe | 150×150 | 1.0-3.0 |

1. What is your major market?

90% of our tubes are exported . We mainly sell to Southeast Asia, Europe and Australia

We sell to the countries like Thailand ,India,Vietnam ,Indonesia ,Malaysia ,German,Poland, Italy,Australia.

2. What is your location?

We are located in Foshan City which is a famous stainless steel production base.

Our new workshop is located in Sanshui District, Foshan City.

3.What's the annual output?

We produce more than 25000 tons stainless steel tubes in a year.

4. What is your welding method?

All of our tubes are welded by tig welding methods. Our tubes can get fully welding and smooth inner welding, without blisters, leak welding or black line. All of our tube are good for tube bending.

5. How do you control the quality during the polishing process?

1)As for the mirror polish square/rectangular tube , we will polish it as least four times)

2)During the polishing processing, we set a special sanding wheel to polish the welding part.

3)To avoid scratches,after polishing,the tubes will be lay out on a steel crate then we could lift the whole steel crate instead of the tube.

4)On the other hand, we use the gunny bags to protect the tube's surface when the tube laying-out.

6. How do you inspect the tubes?

The Quality inspectors inspect the tubes during each production processes from raw material,tube welding,polishing,packaging.

1) Before the production of each machine, we will have the first checked and record the data.

2). During the production, our inspector and engineer have been carefully moniting and we record the data every two hours.

CONTACT INFORMATION--------------------

Sandy (Sales)