High Speed Steel 1.3247, M42 Alloy Steel Tool Steel

Guangzhou Changfeng Steel Co., Ltd.- Type:Alloy Steel Bar

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Technique:Hot Rolled

- Application:Tool Steel Bar, Die Steel Bar

- Surface Treatment:Black, Grinded, Machined

- Alloy:Alloy

Base Info

- Model NO.:1.3247, M42, SKH59, W2Mo9Cr4VCo8

- Special Use:Used for Cutters in Common Use

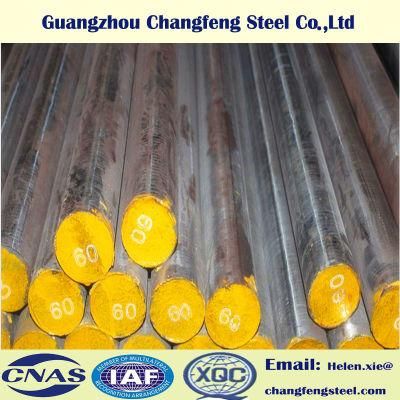

- The Epidermis:Black or Silver Material

- Length:1000-6000mm

- Dimensions:Dia 6-400mm

- Grade:1.3247, M42, Skh59, W2mo9cr4vco8

- Annealed Hardness:255hbs

- Certificate:ISO , Mill Certificate

- Test:SGS , Ut 100% , Element Testing

- Payment:30% Deposit, Blance by L,C at Sight or T,T

- Delivery Quantity:Include MOQ

- Transport Package:Export Standard Packing or Customers′demand

- Specification:DIN JIS AISI GB

- Trademark:CF STEEL

- Origin:China

- HS Code:7225

- Production Capacity:1000t,Month

Description

Basic Info.

Model NO. 1.3247, M42, SKH59, W2Mo9Cr4VCo8 Special Use Used for Cutters in Common Use The Epidermis Black or Silver Material Length 1000-6000mm Dimensions Dia 6-400mm Grade 1.3247, M42, Skh59, W2mo9cr4vco8 Annealed Hardness 255hbs Certificate ISO / Mill Certificate Test SGS / Ut 100% / Element Testing Payment 30% Deposit, Blance by L/C at Sight or T/T Delivery Quantity Include MOQ Transport Package Export Standard Packing or Customers′demand Specification DIN JIS AISI GB Trademark CF STEEL Origin China HS Code 7225 Production Capacity 1000t/MonthProduct Description

High Speed Steel 1.3247, M42 Alloy Steel Tool SteelApplication:

Used for cutters in common use.

1) This for high speed steel, tungsten steel adaptable to make strong cutting use wear-resisting, resistance to impact a variety of tools, advanced punching die, screw die;

2) Is need toughness and shape complex tools, milling cutter, drill, etc

Feature:

1) Die steel for manufacturing strong cutting with wear-resistant, resistant to impact a variety of tools;

2) Specially for hard and hi-speed cutting;

Preheat temperature: 730-730 °C

Quenching temperature: 1190-1210 °C

Tempering temperature: Cold drawn, hardness 285 HBS,Cold drawn after annealing condition, hardness 277 HBS;

Heat treatment

Fire: isothermal annealing temperature is 800 ~ 880 °C, with 10 ~ 20 °C, the dHr furnace cooling to about 600 °C, hardness above HB269;

Chemical composition(%)

| C | Si | Mn | P | S | Cr | V | W | Mo | Co |

| 1.~1.15 | ≥0.65 | ≥0.40 | ≤0.030 | ≤0.030 | 3.50~4.50 | 0.95~1.35 | 1.15~1.85 | 9.0~10.0 | 7.50~8.50 |

Quenching methods: oil quenching, air cooling or salt bath quenching;

Delivery state:

forging parts produced with continuous casting and electro-slag re-melting process; rolled as annealed, bright and quenched/tempered steel bars.

Listed specifications are only typical grades; products of required specifications can be developed/produced per international, Chinese or industry standards, or based on agreements with customers.

Packing:

Standard export packing or according to customers' request.

Delivery:

For abundant stock, 15-20 days.

For customized products, 30-50 days.

Our services:

1. Sizes material and others are all at your requirements and can be change

2. Price varies on material , dimensions, finished craft and different payments

3. We are direct manufacturer in machinery manufacturing with experience of many years.

4. Detailed production design can be made according to the information you offered

5. Each material will be passed the UT test

6. We have an adequate inventory, so that we can effect a quick delivery

Our Factory:

Products show: