P20 3Cr2Mo 1.2311 Hot Rolled Flat Steel of Die Steel

Guangzhou Changfeng Steel Co., Ltd.- Technique:Hot Rolled

- Standard:AISI, JIS, ASTM, DIN, BS, GB

- Certification:IS0, RoHS

- Production Process:Ef,Eaf+Lf+Vd,ESR

- Payment Term:30% Deposit, Balance by L,C at Sigth

- Hardeness:28-32HRC

Base Info

- Model NO.:P20, 1.2311, PDS-3

- Test:SGS , Ut 100% , Element Testing

- Techniq.:Forged or Hot Rolled

- Delivery Condition:Hot Rolled, Annealed

- Transport Package:Normal Package&Customers′ Demand

- Specification:thickness 10-460mm

- Trademark:CF STEEL

- Origin:China

- HS Code:7225401000

- Production Capacity:1000t,Month

Description

10-3503000-6000

Delivery time: For abundant stock, 7-15 days.For customized products, 30-50 days.

Packaging: We provide the package according to the export standard or as client's requirements.

About products:

Strict Quality Control

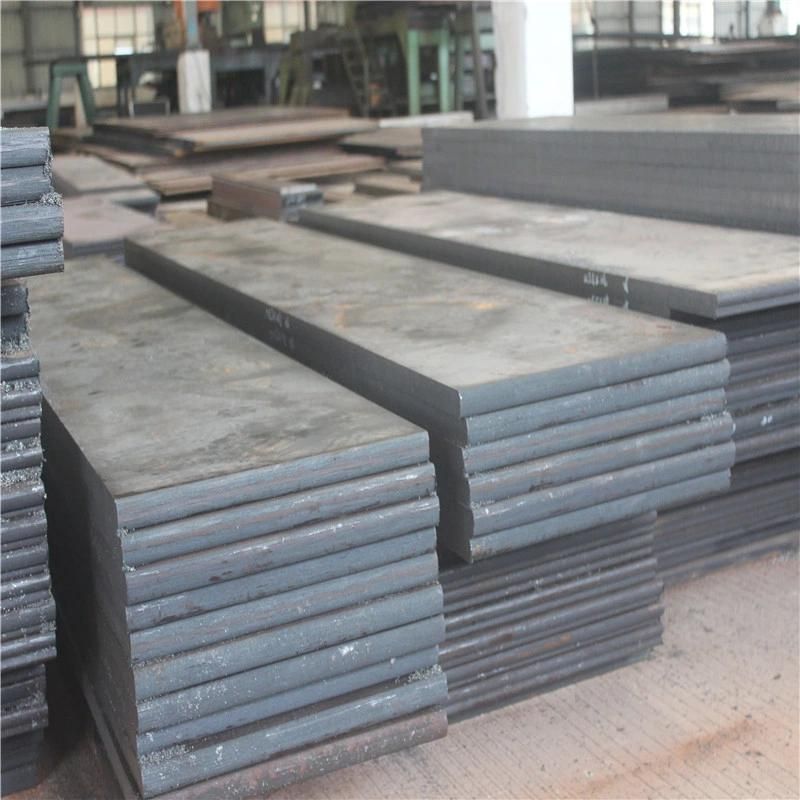

About our warehouse:

Loading Photo

About us:

Guangzhou ChangFeng Steel Co., Ltd. is a professional special steel company, which specialized in exporting mould steel products based in China. With more than 20 years experience in special steel industry, our main products are Plastic Mould Steel, Hot Work Mould Steel, Cold Work Mould Steel, Alloy Structural Steel, Tool Steel, Stainless Steel, Carbon Steel and Forged Block.

To ensure provide high quality products to customers, we have close cooperation with many Chinese first class special steel enterprises, including Baosteel Group, Dongbei Special Steel, Changcheng Special Steel, Hongsheng Heavy Industry, Xingcheng Special Steel, Daye Special Steel.

We have thousand tons of stock materials in our own factory and also can provide processing services to customers. We are full of export experience for many years, the product covers America, Germany, France, Italy, Turkey, Singapore, Thailand, Malaysia, Vietnam, Taiwan, and Middle-East.

After years of development, the company has established a complete quality management and export service system. We have a group of experienced and competent elites and is capable of offering the best service to clients.

Our company equips with large-sized Vertical saw machines, Horizontal saw machines, Milling machines, Grinding machines and other advanced equipments to provide customers with cutting and other processing services.

All the products should be inspected the metallographic analysis, hardness, ultrasonic flaw detection and other strict inspection processes, which meet the standards of DIN, AISI, JIS and GB to ensure their function and quality.

Delivery time: For abundant stock, 7-15 days.For customized products, 30-50 days.

Packaging: We provide the package according to the export standard or as client's requirements.

About products:

Strict Quality Control

About our warehouse:

Loading Photo

About us:

Guangzhou ChangFeng Steel Co., Ltd. is a professional special steel company, which specialized in exporting mould steel products based in China. With more than 20 years experience in special steel industry, our main products are Plastic Mould Steel, Hot Work Mould Steel, Cold Work Mould Steel, Alloy Structural Steel, Tool Steel, Stainless Steel, Carbon Steel and Forged Block.

To ensure provide high quality products to customers, we have close cooperation with many Chinese first class special steel enterprises, including Baosteel Group, Dongbei Special Steel, Changcheng Special Steel, Hongsheng Heavy Industry, Xingcheng Special Steel, Daye Special Steel.

We have thousand tons of stock materials in our own factory and also can provide processing services to customers. We are full of export experience for many years, the product covers America, Germany, France, Italy, Turkey, Singapore, Thailand, Malaysia, Vietnam, Taiwan, and Middle-East.

After years of development, the company has established a complete quality management and export service system. We have a group of experienced and competent elites and is capable of offering the best service to clients.

Our company equips with large-sized Vertical saw machines, Horizontal saw machines, Milling machines, Grinding machines and other advanced equipments to provide customers with cutting and other processing services.

All the products should be inspected the metallographic analysis, hardness, ultrasonic flaw detection and other strict inspection processes, which meet the standards of DIN, AISI, JIS and GB to ensure their function and quality.