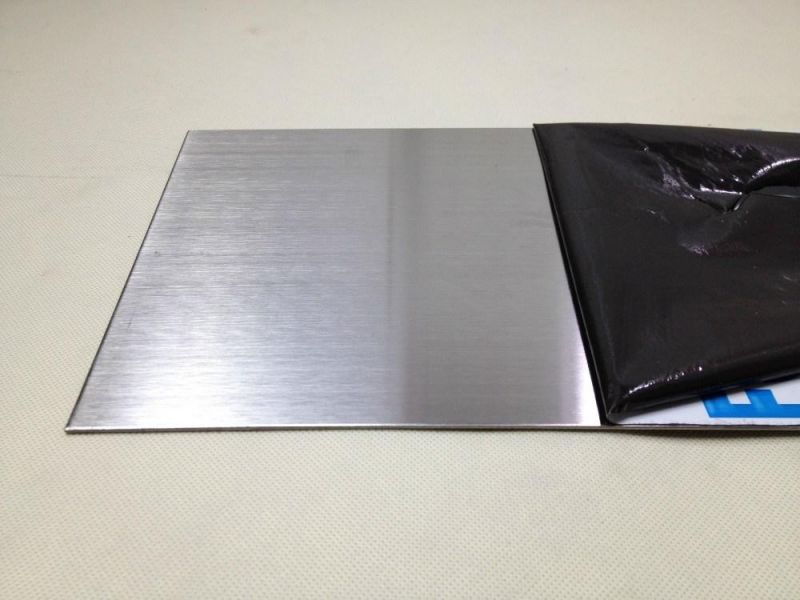

Stainless Steel Grade 201 304 316 316L Stainless Steel Sheets SUS304 SUS316 Stainless Steel Metal Plates in Great Quality with No. 1/2b/Mirror Surface

Shandong Zhongyi Steel Co., Ltd.- After-sales Service:3 Years Warrenty

- Warranty:3 Years Warrenty

- Type:Steel Plate

- Standard:ASTM, GB, JIS, DIN, BS

- Certification:ISO, IBR

- Surface Treatment:Milling

Base Info

- Model NO.:Stainless Steel Sheet

- Technique:Cold Rolled

- Application:Boiler Plate

- Stock:Stock

- Capacity:About 15000 Tons Per Month for The Steel Sheet and

- Thickness:0.2mm and Over 0.2mm, All Available

- Transport Package:Lined with a Waterproof Inner Packaging

- Origin:China

- HS Code:7211190000

- Production Capacity:30000 Tons,Month

Description

Basic Info.

Model NO. Stainless Steel Sheet Technique Cold Rolled Application Boiler Plate Stock Stock Capacity About 15000 Tons Per Month for The Steel Sheet and Thickness 0.2mm and Over 0.2mm, All Available Transport Package Lined with a Waterproof Inner Packaging Origin China HS Code 7211190000 Production Capacity 30000 Tons/MonthProduct Description

Why You Should Choose Zhongyi Steel GroupFor All Your Galvanized Steel Needs

When you work with our manufacturing factory, you're working with one of the most dedicated and professional teams in the industry. We go above and beyond to provide you with the high-quality galvanized steel materials, coils, sheets, and more that you need, without wasting your time, efforts, or investments. Each piece of pre-painted galvanized iron that leaves our premises is of the highest possible quality to make sure that you're satisfied with your purchase, every single time.

Instead of providing you with low-quality, cheap imitations of this exceptional material, we've taken the time to check, perfect, and carefully manufacture the highest caliber of pre-painted galvanized iron.

Which Kinds of Galvanized Steel Products Does the Zhongyi Steel Group Manufacture?

We've got a highly qualified team of manufacturing experts who have the skills and industry-specific experience they need to manufacture a variety of different pre-coated steel products. From coils to sheets, we can process and package your pre-painted galvanized steel materials in the most effective way for your needs and product requirements.

If you'd like to enquire about exactly which products we're able to manufacture to suit your needs, feel free to reach out to us to chat with one of our experts today

Our Products Advantages:

1. Lowest first cost. Galvanizing is lower in first cost than many other commonly specified protective coatings for steel. (The application cost of labour intensive coatings such as painting has risen far more than the cost of factory operations such as galvanizing.)

2. Less maintenance/Lowest long term cost. Even in cases where the initial cost of galvanizing is higher than alternative coatings, galvanizing is almost invariably cheapest in the long term (because it lasts longer and needs less maintenance). And, maintenance causes problems and adds to costs when structures are located in remote areas, and when plant shutdown or disruption to production is involved.

3. Long life. The life expectancy of galvanized coatings on typical structural members is far in excess of 50 years in most rural environments, and 20 to 25 years plus, even in severe urban and coastal exposure.

4. Reliability. Galvanizing is carried out to Australian / New Zealand Standard 4680, and standard, minimum coating thicknesses are applied. Coating life and performance are reliable and predictable.

5. Toughest coating. A galvanized coating has a unique metallurgical structure which gives outstanding resistance to mechanical damage in transport, erection and service.

6. Automatic protection for damaged areas. Galvanized coatings corrode preferentially to steel, providing cathodic or sacrificial protection to small areas of steel exposed through damage. Unlike organic coatings, small damaged areas need no touch up.

7. Complete protection. Every part of a galvanized article is protected, even recesses, sharp corners and inaccessible areas. No coating applied to a structure or fabrication after completion can provide the same protection.

8. Ease of inspection. Galvanized coatings are assessed readily by eye, and simple non-destructive thickness testing methods can be used. The galvanizing process is such that if coatings appear sound and continuous, they are sound and continuous.

9. Faster erection time. As galvanized steel members are received they are ready for use. No time is lost on-site in surface preparation, painting and inspection. When assembly of the structure is complete, it is immediately ready for use, or for the next construction stage.

10. A full protective coating can be applied in minutes; The galvanizing process is not dependent on weather conditions