Hot Sales Sch40 A53 Seamless and Welded Carbon Steel Pipe

Shandong gangpu metal materials Co., Ltd.- Type:Seamless

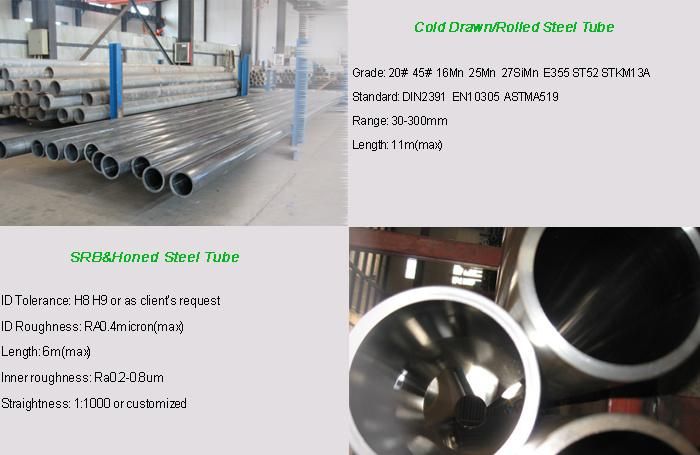

- Technique:Cold Rolled

- Material:Carbon Steel

- Surface Treatment:Black

- Usage:Pipeline Transport, Boiler Pipe, Hydraulic,Automobile Pipe, Oil,Gas Drilling, Food,Beverage,Dairy Products, Machinery Industry, Chemical Industry, Mining, Construction & Decoration, Special Purpose

- Section Shape:Round

Base Info

- Model NO.:q235 q235b q345 q345b s400

- Welding Line Type:Seamless

- Color:Customized Color

- Certificate:ISO

- Sample:Provide

- MOQ:5 Tons

- Transport Package:Wooden Box

- Specification:carbon steel tube 6m

- Trademark:GANGPU

- Origin:China

- Production Capacity:15000 Ton,Year

Description

General Properties The raw material of carbon steel tube is round tube billet. Round tube embryo is cut and processed by cutting machine and the billet with a growth degree of about 1 meter, and is sent to the furnace for heating by conveyor belt.

The raw material of carbon steel tube is round tube billet. Round tube embryo is cut and processed by cutting machine and the billet with a growth degree of about 1 meter, and is sent to the furnace for heating by conveyor belt.

The billet is fed into a furnace to be heated at about 1200 degrees Celsius.

The fuel is hydrogen or acetylene.

The temperature control in furnace is the key problem.

After the round tube billet comes out of the oven, it must go through the pressure punch.

The most common puncher is the cone roll puncher, which has high production efficiency, good product quality, large diameter expansion and can wear a variety of steel.

After perforation, the round tube is successively rolled by three rolls, cross - rolled, or extruded.

After extrusion, take off the pipe and size.

The sizing machine rotates into the steel embryo through the conical drill bit at high speed to drill and form the steel tube.

The inner diameter of steel pipe is determined by the outer diameter length of drill bit of sizing machine.

After sizing, the steel pipe enters the cooling tower and is cooled by spraying water. After cooling, the steel pipe is straightened.

After straightening, the steel tube is sent by conveyor belt to metal flaw detector (or water pressure test) for internal flaw detection.

If there are cracks, bubbles and other problems inside the steel pipe, it will be detected.

Steel pipe quality inspection through strict manual selection.

After quality inspection, paint on the pipe number, specification, production batch number and so on.

And by the crane into the warehouse.

Packing &Shipping FAQ

FAQ

1. who are we?

We are based in Shandong, China, start from 2020,sell to South America(8.00%),Eastern Europe(8.00%),Domestic Market(7.00%),North America(7.00%),South Asia(7.00%),Southern Europe(7.00%),Northern Europe(7.00%),Central America(7.00%),Western Europe(7.00%),Eastern Asia(7.00%),Mid East(7.00%),Oceania(7.00%),Africa(7.00%),Southeast Asia(7.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

stainless steel,carbon steel,Lead plate,Aluminum plate

4. why should you buy from us not from other suppliers?

We specialized in stainless steel plate ,stainless steel pipe, wear resistant Steel Plate,weather resistant steel plate,alloy steel plate,high strength steel plate, tank plate, high pressure vessel plate, ship steel plate