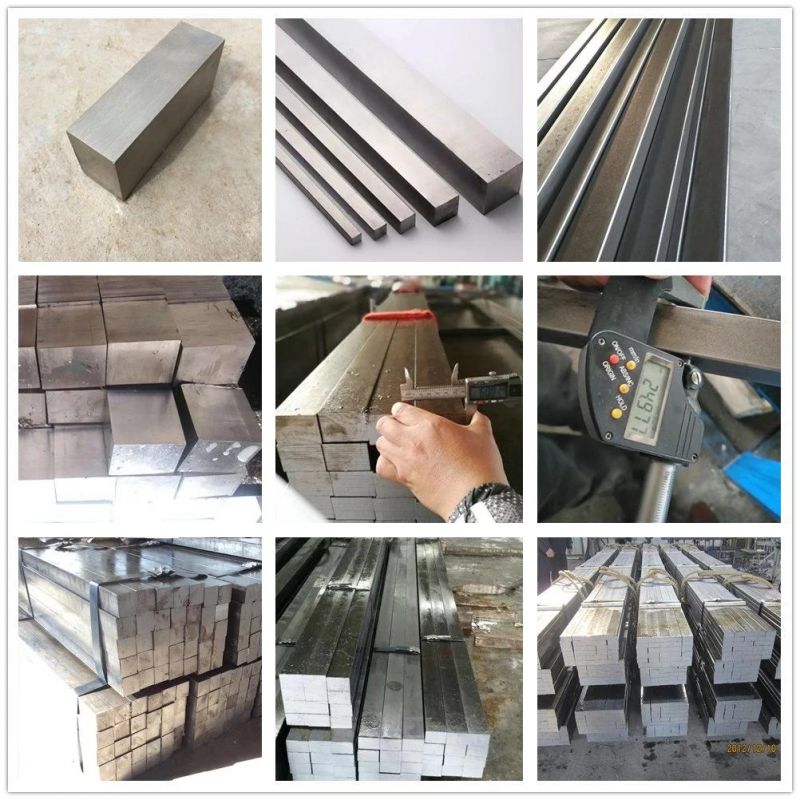

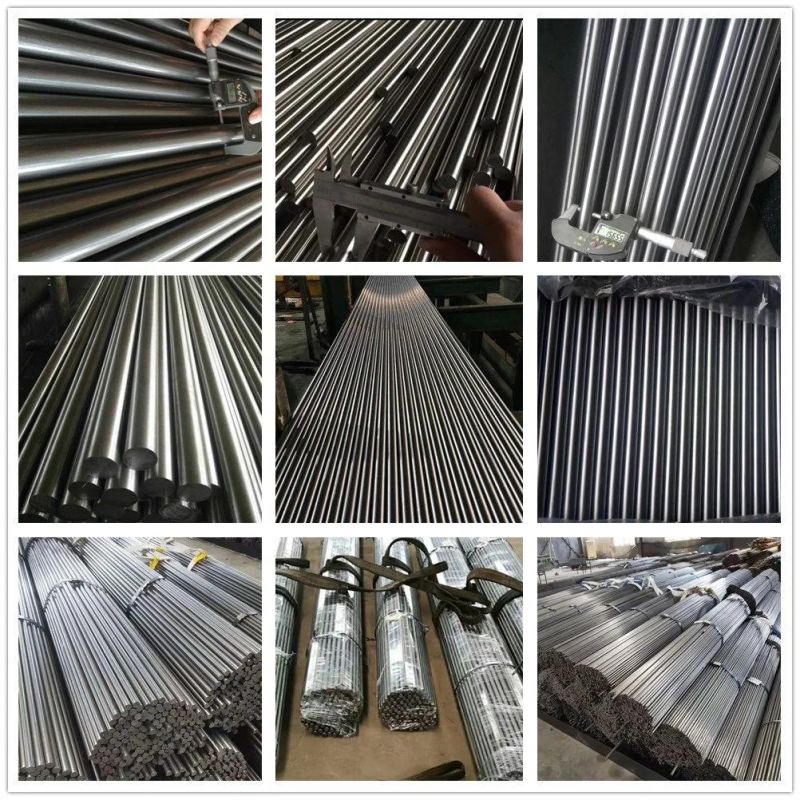

Cold Drawn Steel Round Square Hexagonal Bar S45c C45 1045 Ck45

Laiwu Xincheng Metal Co., Ltd.- Type:Alloy Steel Bar

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Technique:Cold Drawn

- Application:Structural Steel Bar, Tool Steel Bar, Die Steel Bar

- Surface Treatment:Polished

- Alloy:Alloy

Base Info

- Model NO.:AISI 1045 Medium Carbon Steel

- Special Use:Mold Steel, Free Cutting Steel, Cold Heading Steel

- Products Name:Cold Drawn Steel Round Square Hexagonal Bar

- Tolerance of Cold Drawn Steel Bar:H8 H9 H10

- Straightness of Cold Drawn Steel Bar:Max 0.8mm,M

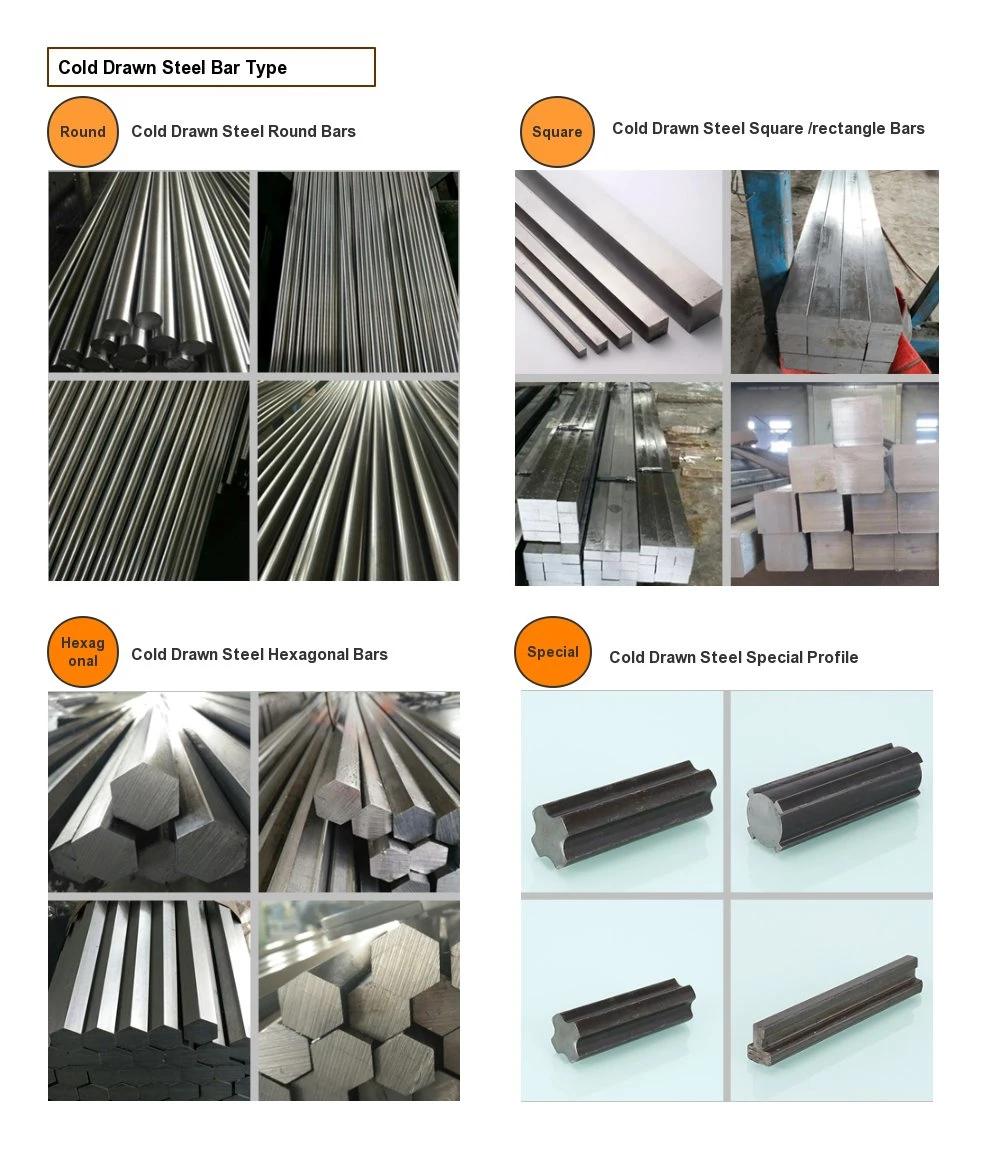

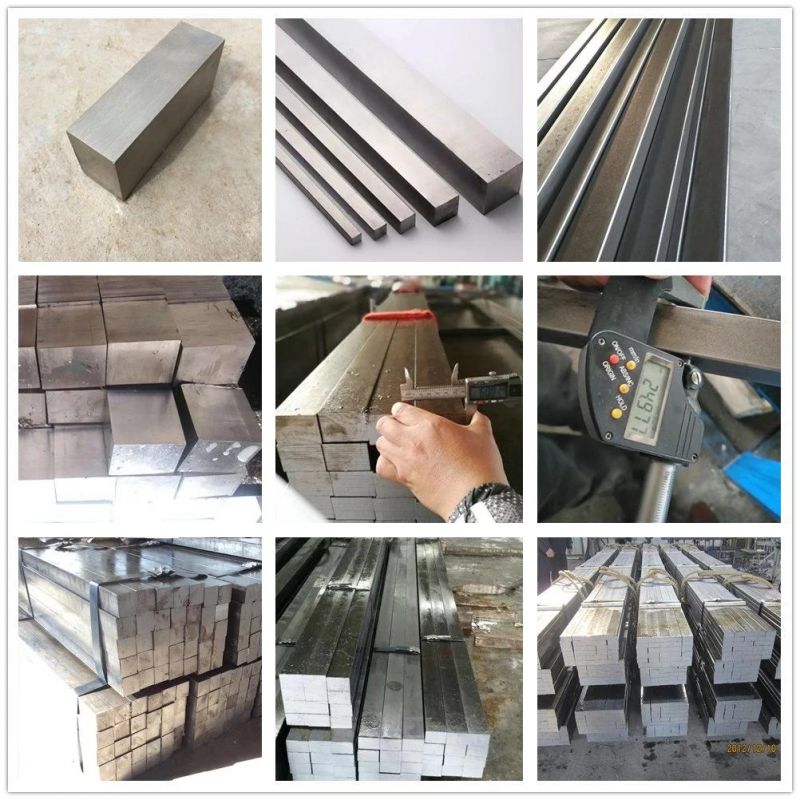

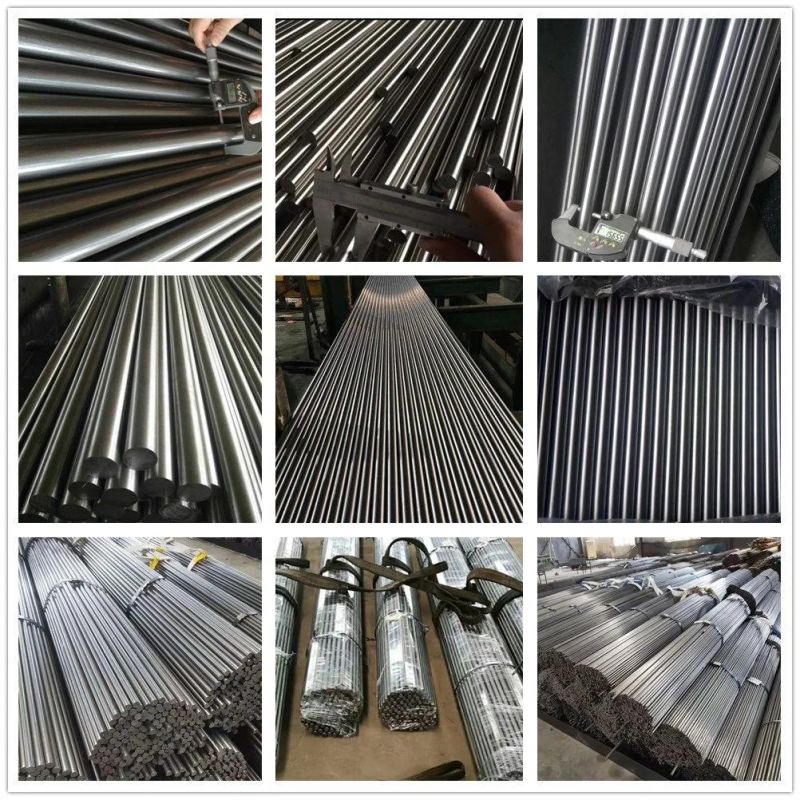

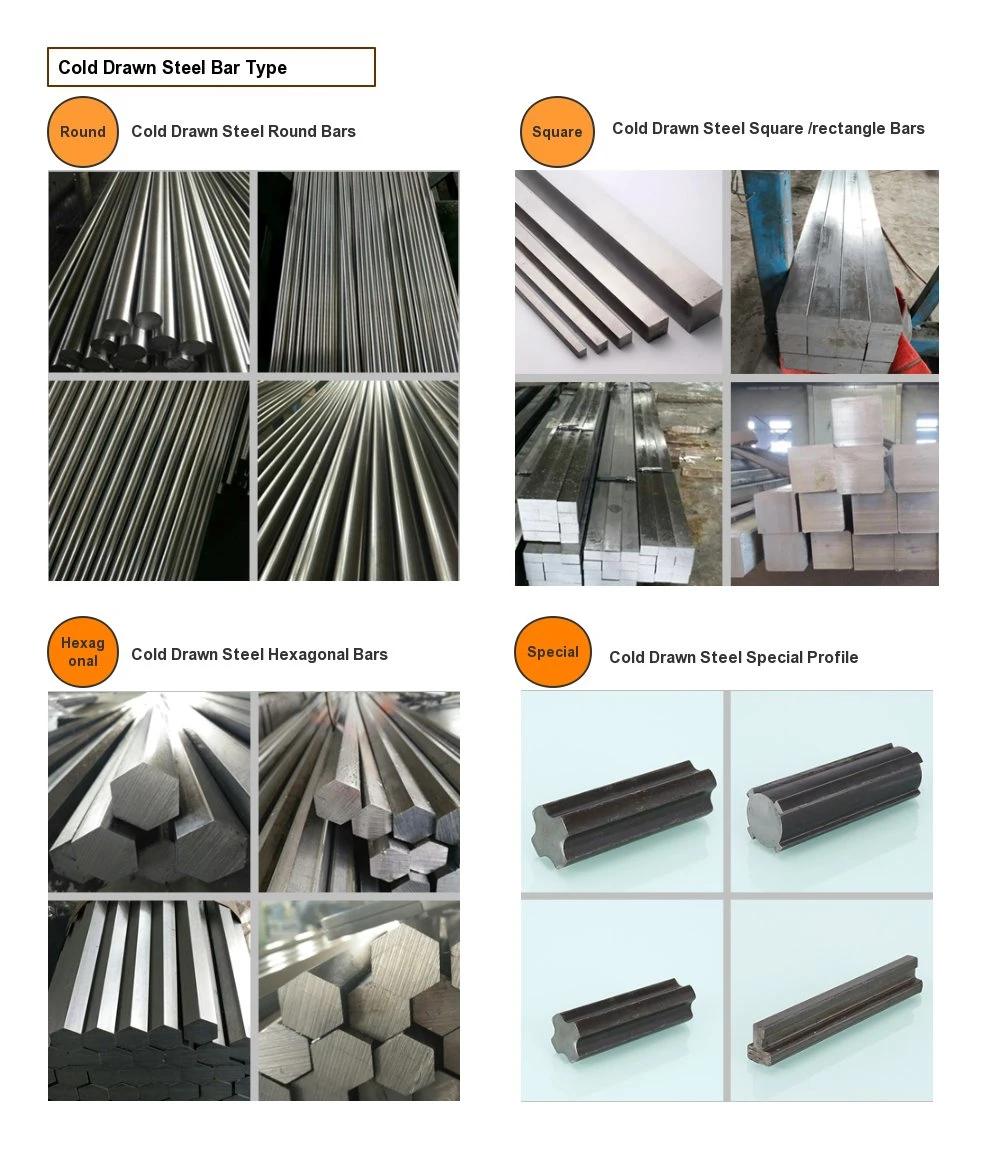

- Shape of Cold Drawn Steel Bar:Round, Square,Hexagonal

- Transport Package:Anti-Rust

- Specification:M6-M100

- Origin:China

- Production Capacity:3000tons,Month

Description

ProcessSize offer range (inches) Size offer range (mm) Cold Drawing Round Sizes 0.235 - 4.700″ 5-120 Hexagon Sizes 0.235 - 3.000″ 5-75 Square Sizes 0.235 - 4.700″ 5-120 Special Sections Please RFQ Please RFQ Annual Capacity 30,000 Tons 30,000 Tons Turning & Polishing Sizes 0.600-4.700'' 15-120 Annual Capacity 50,000 Tons 50,000 Tons

4.Tolerances and Properties

5.Our mian grades:

6.Delivery time:7-30 days after deposit received

7.Trade term: FOB CFR CIF EXW

8. Mark: including steel material, heat No., pieces, weight, date and so on.

9.MOQ:2tons

10.Advantages of cold drawn steel bars:

1.It can remove the Size and Section which provides Tighter tolerances which Reduces machining losses.

2.It can remove the Steel Surface Finish which Reduces surface machining & improves quality.

3.It can remove the Straightness which Facilitates automatic bar feeding in CNC.

4.It can increase the Mechanical Properties which Can reduce the need for hardening.

5.It can improve the Machinability and Productivity which Enables higher machining feeds, high tool life, yield & speeds and improved machined finish.

4.Tolerances and Properties

| Hot Rolled | Cold Drawn | Turned & Polished | Turned, Ground & Polished | Drawn, Ground & Polished | |

| Diameter | +/- 0.008" | +/- 0.001" | +/- 0.001" | +/- 0.0002" | +/- 0.0002" |

| Straightness | 0.050" Max Per Foot | 0.005" Max Per Foot | 0.005" Max Per Foot | 0.005" Max Per Foot | 0.005" Max Per Foot |

| Yield Strength | Comparison Standard | Up to 80% Over Hot-Rolled | Same as Hot-Rolled | Same as Hot-Rolled | Up to 80% Over Hot-Rolled |

| Tensile Strength | Comparison Standard | Up to 40% Over Hot-Rolled | Same as Hot-Rolled | Same as Hot-Rolled | Up to 40% Over Hot-Rolled |

| Machinability | Comparison Standard | Up to 25% Over Hot-Rolled | Same as Hot-Rolled | Same as Hot-Rolled | Up to 25% Over Hot-Rolled |

| Surface Finish | Rough Iron Oxide | 30 Ra | 45 Ra | 10 Ra | 10 Ra |

5.Our mian grades:

| Type | JIS | AISI | Application |

| Carbon | S10C, S20C, S25C, S35C, S45C, S48C, CH25K, CH25KS, CH35KS, CH38K, CH45K, CH45KS | 1010, 1018, 1020, 1045, 1050 | Oil Pressure Shaft/Automotive Parts |

| Allay Steel | SMn443, SCr420, SCr440, SCM415, SCM420, SCM435, SCM440, SNCM220, SNCM420 | 1541, 5120, 5140, 4115, 4120, 4135, 4140, 8620, 4320 | CV JOINT, Differential Gear |

| Free cutting Steel | SUM21, SUM22, SUM23, SUM43, SUM24L, SUM24EZ | 1213, 1141, 1144, 12L14 | CNC Machine |

6.Delivery time:7-30 days after deposit received

7.Trade term: FOB CFR CIF EXW

8. Mark: including steel material, heat No., pieces, weight, date and so on.

9.MOQ:2tons

10.Advantages of cold drawn steel bars:

1.It can remove the Size and Section which provides Tighter tolerances which Reduces machining losses.

2.It can remove the Steel Surface Finish which Reduces surface machining & improves quality.

3.It can remove the Straightness which Facilitates automatic bar feeding in CNC.

4.It can increase the Mechanical Properties which Can reduce the need for hardening.

5.It can improve the Machinability and Productivity which Enables higher machining feeds, high tool life, yield & speeds and improved machined finish.