Alloy Smo 254 Stainless Steel Plate 254 Smo Plate Smo 254 Alloy

Wuxi City Ge Ming Sheng Steel Trading Co., Ltd- Type:Stainless Steel Sheets

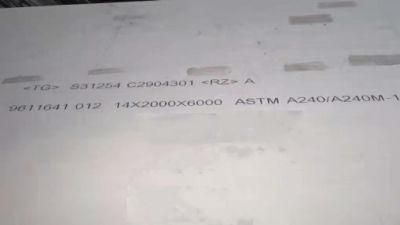

- Standard:ASTM

- Grade:S31254 254smo

- Certification:ISO, AISI, ASTM

- Shape:Flat

- Technique:Cold Rolled

Base Info

- Model NO.:254SMO

- Surface Treatment:Bright

- Transport Package:Wooden Pallet

- Specification:1220*2440, 1500*3000, 1500*6000, 2000*6000mm

- Trademark:TISCO BAO STEEL

- Origin:China

- HS Code:7219320000

- Production Capacity:50000kgs

Description

Basic Info.

Model NO. 254SMO Surface Treatment Bright Transport Package Wooden Pallet Specification 1220*2440, 1500*3000, 1500*6000, 2000*6000mm Trademark TISCO BAO STEEL Origin China HS Code 7219320000 Production Capacity 50000kgsProduct Description

Alloy SMO 254 Stainless Steel plate 254 smo plate smo 254 alloyAlloy 254 SMO is a very high end, molybdenum and nitrogen alloyed super austenitic stainless steel with low carbon content. It demonstrates outstanding resistance to pitting, crevice corrosion stress cracking, and corrosion fatigue uniform corrosion. Alloy 254 SMO is substantially stronger than the common austenitic grades, with strength nearly twice that of 300 series stainless steel. It is also characterized by high ductility and impact strength. With high levels of chromium, molybdenum, and nitrogen, Alloy 254 SMO is frequently used in high chloride environments, such as brackish water, seawater, pulp mill bleach plants, and other chloride process streams. In some applications it has even been found to be a more cost effective substitute for high nickel and titanium alloys.

APPLICATIONS:

Due to its high levels of molybdenum and nickel, Alloy 254 SMO is frequently used in high chloride environments. Examples of applications that call for the used of Alloy 254 SMO include:

- Petroleum production

- Saltwater handling

- Food and chemical processing equipment

- Pulp mill bleach systems

- Flue gas desulphurization scrubbers

- Tall oil distillation columns

- Offshore oil & gas production equipment

- Desalination equipment

STANDARDS:

- ASTM/ASME: UNS S31254

- EURONORM: FeMi35Cr20Cu4Mo2

- DIN: 2.4660

ORROSION RESISTANCE

- Excellent resistance to pitting and crevice corrosion due to its high chromium, molybdenum, and nitrogen content

- Has a very low carbon content, which means there is very little risk of carbide precipitation during heating

- Possesses very good resistance in water containing chlorides, therefore, it is suitable for use in seawater as it can be exposed to it for prolonged periods without suffering from crevice corrosion