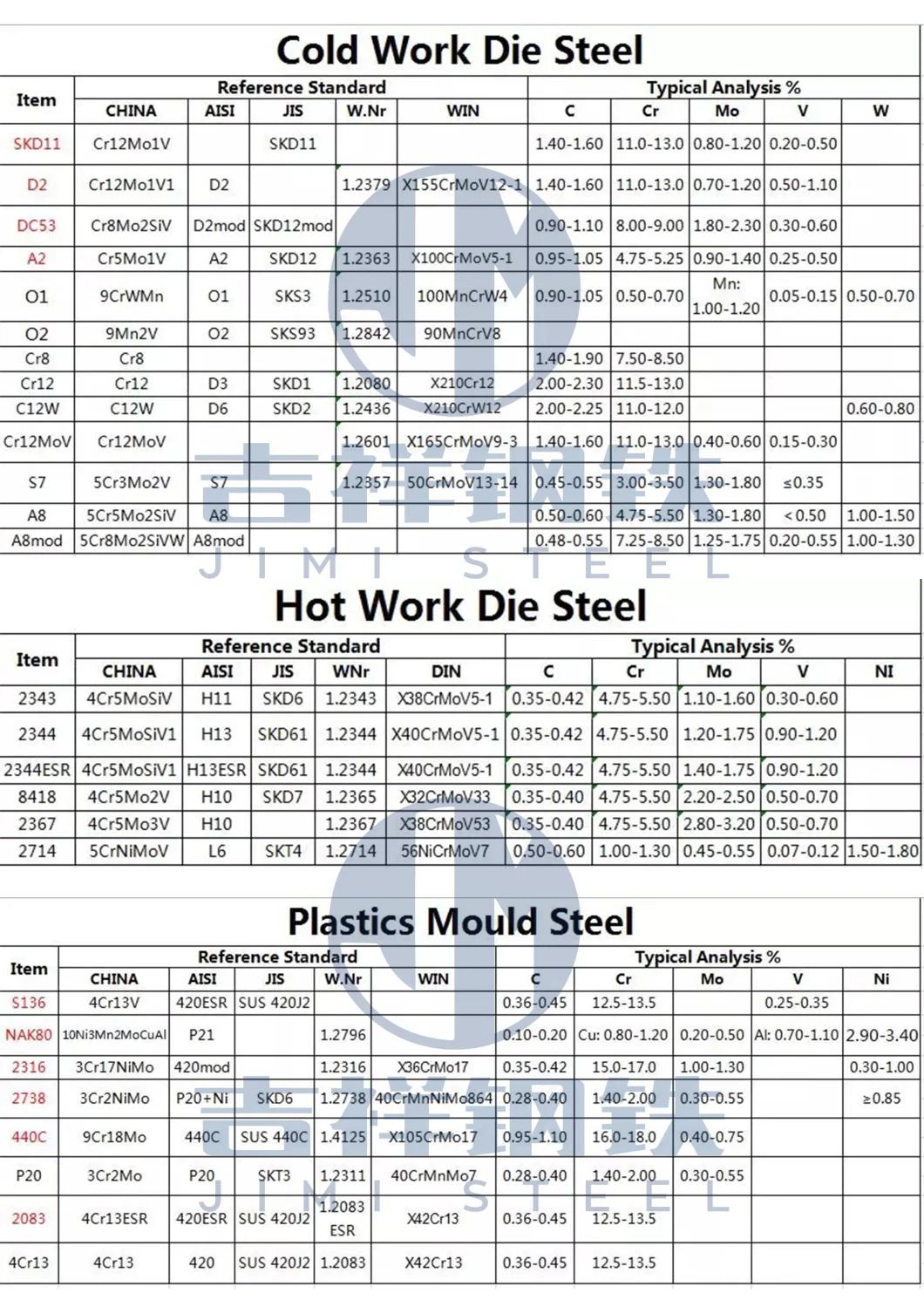

1.2083, 1.2085, 1.2311, 1.2312, 1.2343ESR, 1.2767, Nak80 Material Custom Injection Plastic Mould Black Surface Forging Steel Flat Bar

HK JIMI STEEL CO., LTD.- Type:Alloy Steel Bar

- Standard:AISI, ASTM, DIN, JIS, GB, BS

- Composition:Alloy Steel

- Technique:Hot Rolled

- Shape:Flat

- Surface Treatment:Black Surface,Peeled,Polishing,Rough Turned

Base Info

- Model NO.:1.2085,3Cr17+S,1.2083,1.2311,1.2343ESR,1.2767,NAK8

- Special Use:Mold Steel

- Application:Tool Steel Bar

- Brand:HK Jimi Steel

- International Standard:GB 3cr17+S,JIS SUS420f,DIN 1.2085

- Size:10~300mm*155~2200mm*2000~5000mm

- Steel Type:Alloy Steel,Plastic Mould Steel,1.2085,SUS420f

- Test:SGS,Ut 100%,Element Testing

- Hardness:Annealed,28-38HRC

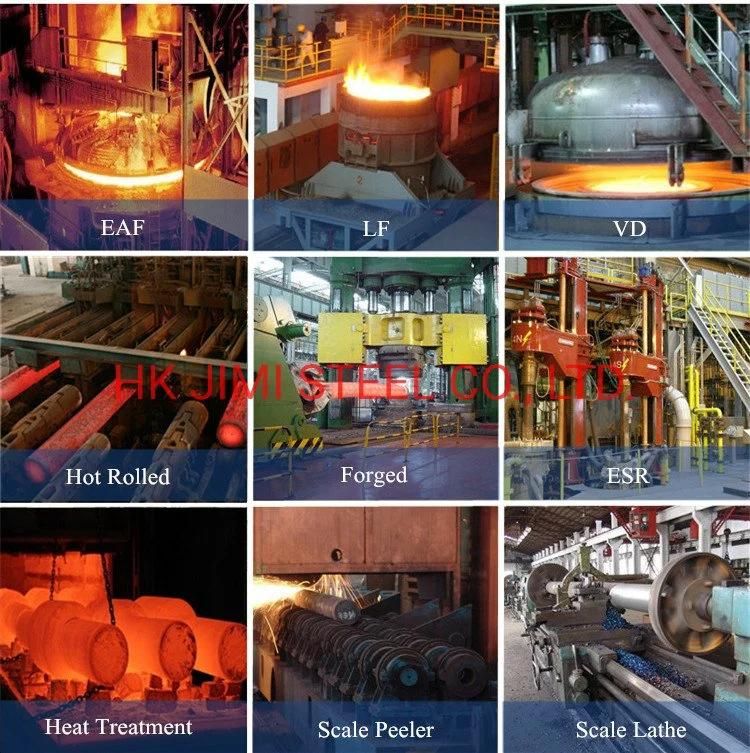

- Delivery Condition:Hot Rolled,Cold Drawn,Forged,Eaf,ESR

- Status:Round Bars,Flats,Big Plates,Blocks

- Surface Require:Black, Peeled, Polished,Machined ,Grinded,Turned

- Tolerance of Size:-0,+5mm

- Features:Strong Corrosion Resistance

- Applications:Acid Resistant Die Frame and Support Tools

- Service:24 Hours,7 Days Online,15 Days Delivery

- Customized:ODM, OEM

- Trade Style:CIF,Fob,EXW,CFR

- Transport Package:Container,Bulk Cargo

- Specification:20GP,40GP,40HQ

- Trademark:ISO9000,SGS

- Origin:China

- HS Code:7228

- Production Capacity:5000 Tons Per Month

Description

6:HEAT TREATMENT:

Usually no heat treatment is required

Soft annealing:

850 to 880 °C for about 2 to 5 hours

slow controlled cooling, further cooling in air, annealing hardness max. 240 HB

Hardening:

1000 to 1030 °C

keeping curing temperature for 30 minutes

quenching in oil is preferable

obtainable hardness: 48 HRC

Tempering:

slow heating to tempering temperature immediately after hardening;

minimum time in furnace: 2 hour per 20 mm part thickness;

tempering twice is recommended

7: Delivery condition

For hot forged or hot rolled bar, usually the delivery condition is hot forged or rolled, annealed, rough turned.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface.

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

8: manufacturing technique

9: About us

Hong Kong JIMI STEEL (XINGXIONG CO., Ltd) XINGXIONG Co., Ltd. Was established in 2012, located in the Shunde District of Guangdong Province, It is an import and export trading company mainly engaged in advanced special steel, die steel, alloy steel, and steel processing general machinery and equipment. The company adheres to the concept of "high quality, high requirements and good faith",

Cooperating with more than 20 famous steel mills in China, rich in spot stock of products.

Our company has a variety of processing equipment and all kinds of inspection and testing equipment, such as horizontal sawing machine, vertical sawing machine, milling machine, bilateral milling machine, precision milling machine, plane grinder and so on. The products with short producing time, excellent quality and high precision can provide a high-quality product choice for the vast number of customers at home and abroad.

Our customer group spread all over the domestic provinces and cities, abroad including Europe, the United States, Australia, the Middle East, Southeast Asia and other more than 20 countries and regions, along with over 100 long-term stable cooperation customers...Choosing Xingxiong will bring you a better experience.