Cold Drawn En 10305-4 E235 E255 E355 +N Precision Seamless Steel Tubes for Hydraulic

Guangzhou Kingmetal Steel Industry Co., Ltd.- Type:Seamless

- Technique:Cold Drawn

- Material:Alloy Steel

- Surface Treatment:Oiled

- Usage:Hydraulic,Automobile Pipe, Special Purpose

- Section Shape:Round

Base Info

- Model NO.:EY-PT

- Wall Thickness:0.5 - 6 mm

- Length:2-12m

- Delivery Time:15-30 Days After Down Payment

- Alloy or Not:Non Alloy

- Standard or Not:Standard

- Secondary or Not:Non Secondary

- Price Term:Fob, CIF, CNF

- Payment:L,C, T,T

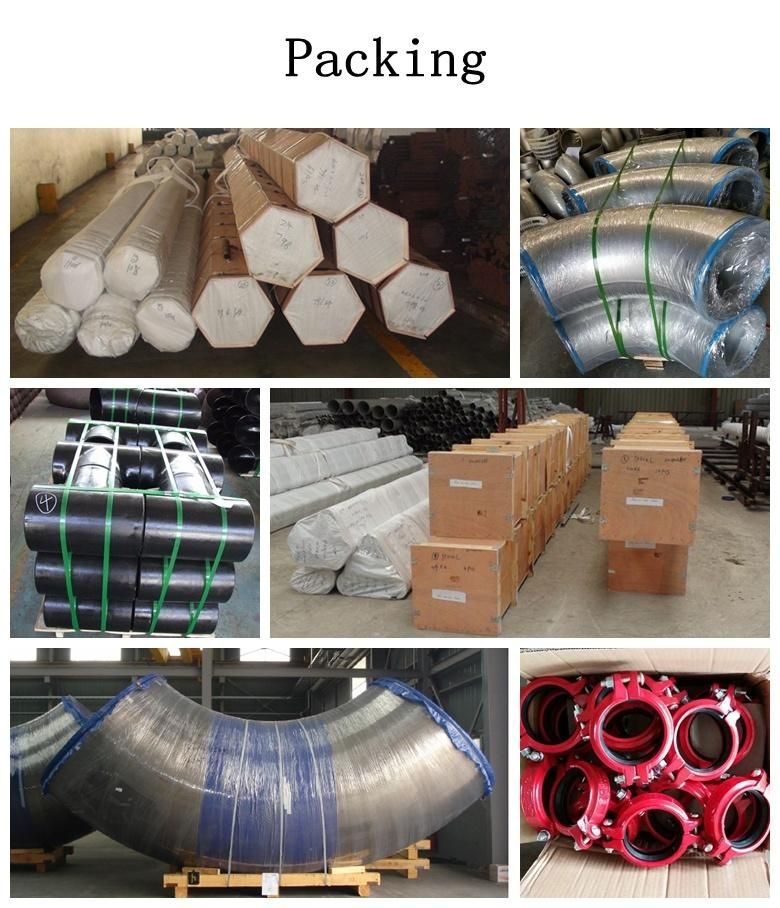

- Transport Package:Export Standard Packing

- Specification:3.75 - 80mm

- Trademark:Kingmetal

- Origin:China (Mainland)

- HS Code:730419

- Production Capacity:2000ton,Tons Per Month

Description

Table 1- Chemical composition

Steel Grade

C%

Si%

Mn%

P%

S%

AL%

E215

≤0.10

≤0.05

≤0.7

≤0.025

≤0.025

≥0.025

E235

≤0.17

≤0.35

0.4-1.2

≤0.025

≤0.025

E255

≤0.21

≤0.35

0.4-1.1

≤0.025

≤0.025

E355

≤0.22

≤0.55

≤1.6

≤0.025

≤0.025

Table 2 - Mechanical properties at room temperature

Delivery Condition

BK

BKW

GBK

NBK (N)

Steel Grade

Rm

A %

Rm

A %

Rm

A %

Rm

ReH

A %

Mpa (Min)

(Min)

Mpa(Min)

(Min)

Mpa(Min)

(Min)

Mpa(Min)

Mpa(Min)

(Min)

E215

430

8

380

12

280

30

290~430

215

30

E235

480

6

420

10

315

25

340~480

235

25

E255

580

5

520

8

390

21

440~570

255

21

E355

640

4

580

7

450

22

490~630

355

22

End Shape

Beveled end, plain end, vanished, or adding plastic caps to protect the two ends as per customer's

requirements

Surface

Treatment

Oiled, Galvanized, Phosphate etc

Technique

Cold drawn & cold rolled

Application

1. Automotive and mechanical pipes

2. Petroleum cracking pipes

3. High Pressure Boiler Pipe

4. Low and middle pressure fluid transportation pipeline

5. Chemical fertilizer equipment pipes

6. Heat exchanger pipes

Delivery

Conditions

1. BK (+C)

No heat treatment after last cold forming process.

2. BKW (+LC)

After last heat treatment there is a light finishing pass (cold drawing)

3. BKS (+SR)

After the final cold forming process the tubes are stress relieve annealed.

4. GBK (+A)

After the final cold forming process the tubes are annealed in a controlled atmosphere.

5. NBK (+N)

After the final cold forming process the tubes are annealed above the upper transformation

point in a controlled atmosphere.