High Frequency Welded Longitudinal Spiral Fin Tube Pipe

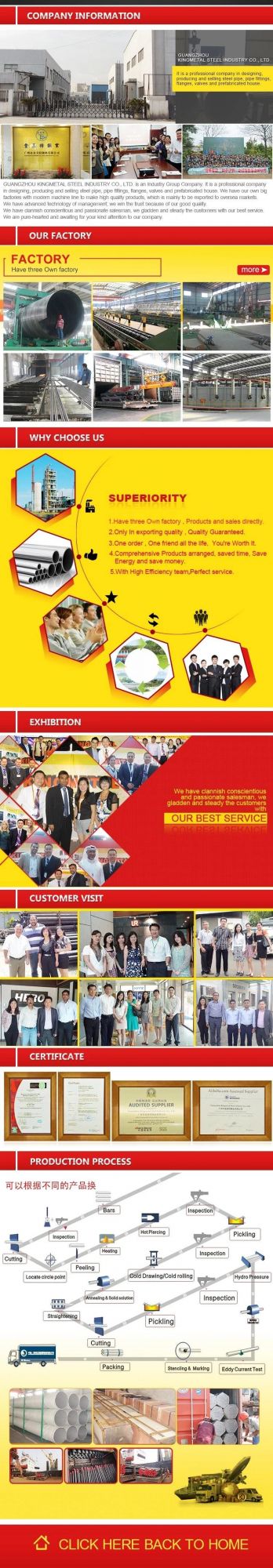

Guangzhou Kingmetal Steel Industry Co., Ltd.- Type:Welded

- Technique:Cold Drawn

- Material:Stainless Steel ,Carbon Steel

- Surface Treatment:Oiled

- Usage:Pipeline Transport, Boiler Pipe, Construction & Decoration, Special Purpose

- Section Shape:Round

Base Info

- Model NO.:KM-221

- Size:1,2′′--12′′

- Wt:0.5mm-2.5mm Sch30,Sch40,Std,Xs,Sch80,Sch160,Xxs

- Length:Less Than 12m

- Ends:1) Plain 2) Beveled

- Inspection:with Hydraulic Testing, Eddy Current , Infrared

- Loading Port:Chinese Main Port

- Delivery Time:7-30 Days Ex Mill

- Transport Package:Standard Sea-Worthy Package

- Specification:1,2′′--12′′

- Trademark:Kingmetal

- Origin:China

Description

Items

Code

Dimensions

Tolerances

Tube outside diameter

D1

Φ25~Φ219 mm

±0.2 mm

Fin outside diameter

D2

Φ37~Φ279 mm

±0.75 mm

Fin pitch

M

4~90 mm

±0.2 mm

Fin height

H

6~30 mm

±0.75 mm

Tube thickness

δ1

2~16 mm

±0.15 mm

Fin thickness

δ2

0.8~2.5 mm

±0.1 mm

Unfinned tube ends length

L1

customized

±1‰*L1 mm

Unfinned tube ends length

L2

customized

±1‰*L2 mm

Maximum tube length

L

0.5~25 m

±1‰*L mm

Ordering and Delivery

For a given pipe or tube size, the desired heat transfer surface area per unit length of tube can be obtained by specifying the appropriate fin height, fin thickness and number of fins per inch.

If the whole transfer surface area of the finned tube is A and the transfer surface area of the tube is A0, then nominal the ratio A/A0 should be 5 to 12.