S20c C22 1020 A36 Cold Drawn Steel Round Bars / Cold Rolled Steel Rod

Laiwu Xincheng Metal Co., Ltd.- Type:Carbon Steel Bar

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Technique:Cold Drawn

- Application:Structural Steel Bar, Tool Steel Bar, Die Steel Bar

- Surface Treatment:Polished

- Alloy:Non-alloy

Base Info

- Model NO.:S20C C22 1020 A36

- Special Use:Mold Steel, Free Cutting Steel, Cold Heading Steel

- Tolerance:H8,H9,H10,H11

- Surface:Bright

- MOQ of Cold Drawn Steel Bars:1ton Per Size

- Length of Cold Drawn Steel Bars:6m or as Required

- Packing of Cold Drawn Steel Bars:Anti-Rust Packing

- Transport Package:Anti-Rust Packing

- Specification:M6-M100

- Trademark:Laiwu Xincheng

- Origin:China

- HS Code:72155000

- Production Capacity:3000tons,Month

Description

Over 80 to 120-0.087 -0.14 -0.22 (-0.00343") (-0.00551") (-0.00866")

7.Application of cold drawn steel bar:

Hardware tools, auto parts, standard parts, fasteners common shaft, machinery manufacturing, light industry, hardware, bicycles, cars, motorcycles, textile machinery, transformers and other machinery industry etc

8.Straightness of our cold drawn steel bars: Max 0.5mm/m

9.Advantages of cold drawn processing:

1.It can remove the Size and Section which provides Tighter tolerances which Reduces machining losses.

2.It can remove the Steel Surface Finish which Reduces surface machining & improves quality.

3.It can remove the Straightness which Facilitates automatic bar feeding in CNC.

4.It can increase the Mechanical Properties which Can reduce the need for hardening.

5.It can improve the Machinability and Productivity which Enables higher machining feeds, high tool life, yield & speeds and improved machined finish.

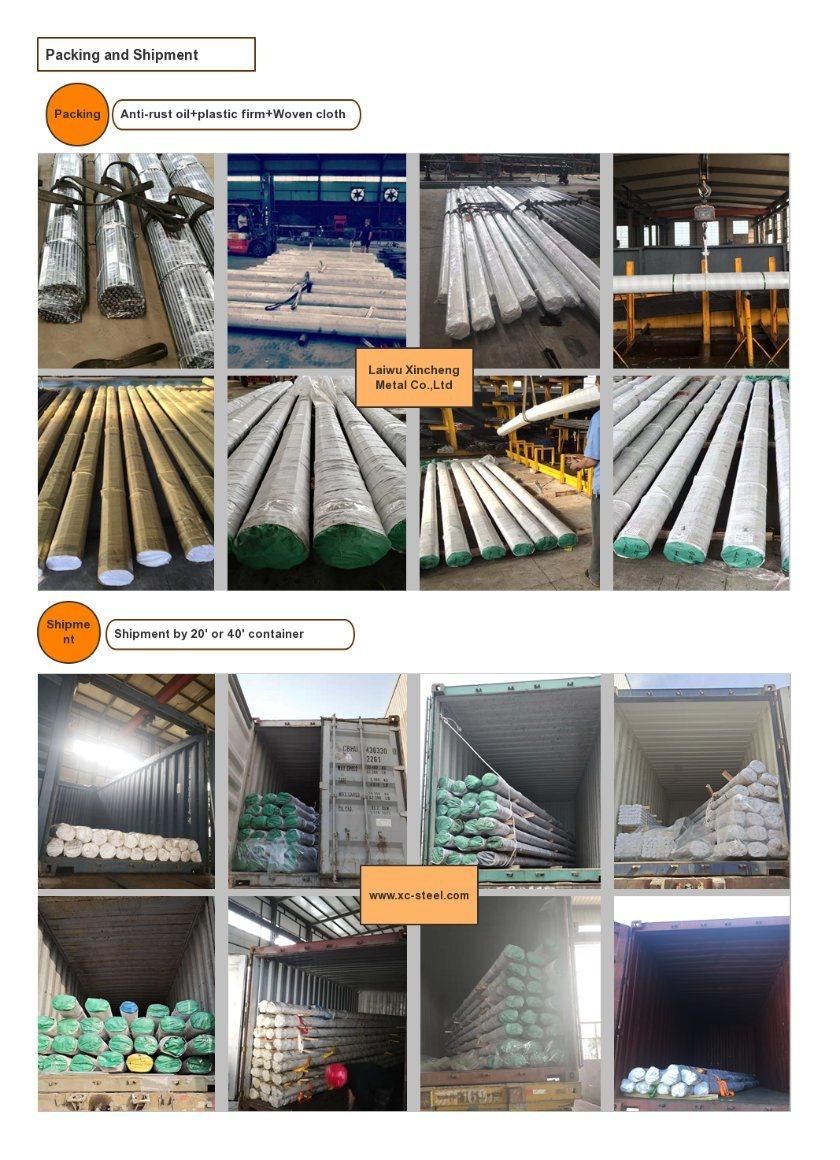

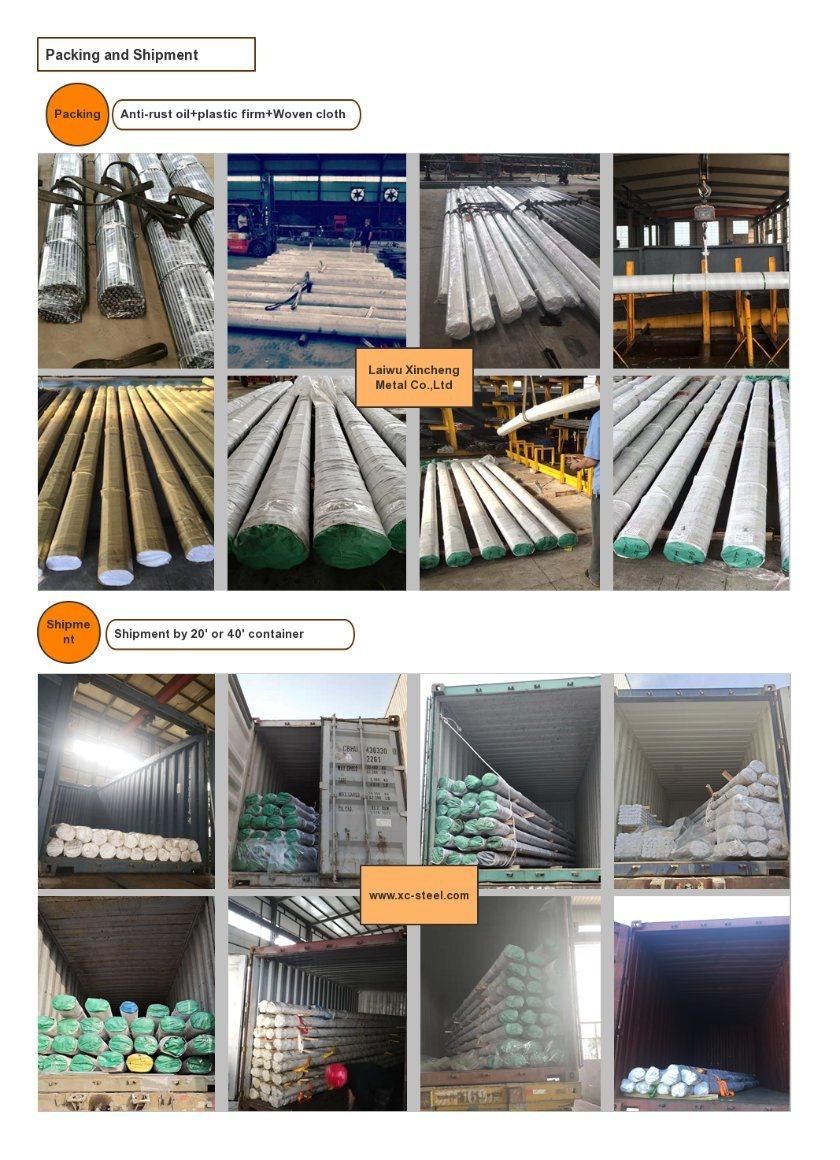

10.Packing of cold drawn steel bars:

a. Surface put anti-rust oil

b.Plastic firm rapped

c.Woven cloth outside to make bundle weight 1000kg or as required

d.Put label on each bundle, including: heat number, size, length, quantity in pcs and weight, origin etc.

e. Other way of packing to be discussed

11.Payment term: TT, LC

12.Quality inspection:

Size tolerance, Surface check, Spectral Tested, Microstructure Tested,Hardness Test,Macrostructure Test,UT test and so on.

7.Application of cold drawn steel bar:

Hardware tools, auto parts, standard parts, fasteners common shaft, machinery manufacturing, light industry, hardware, bicycles, cars, motorcycles, textile machinery, transformers and other machinery industry etc

8.Straightness of our cold drawn steel bars: Max 0.5mm/m

9.Advantages of cold drawn processing:

1.It can remove the Size and Section which provides Tighter tolerances which Reduces machining losses.

2.It can remove the Steel Surface Finish which Reduces surface machining & improves quality.

3.It can remove the Straightness which Facilitates automatic bar feeding in CNC.

4.It can increase the Mechanical Properties which Can reduce the need for hardening.

5.It can improve the Machinability and Productivity which Enables higher machining feeds, high tool life, yield & speeds and improved machined finish.

10.Packing of cold drawn steel bars:

a. Surface put anti-rust oil

b.Plastic firm rapped

c.Woven cloth outside to make bundle weight 1000kg or as required

d.Put label on each bundle, including: heat number, size, length, quantity in pcs and weight, origin etc.

e. Other way of packing to be discussed

11.Payment term: TT, LC

12.Quality inspection:

Size tolerance, Surface check, Spectral Tested, Microstructure Tested,Hardness Test,Macrostructure Test,UT test and so on.