High Quality Hot Sale AISI SUS 430 321 309S 904L 420 310S 201 316L 304 Stainless Steel Coil

Wuxi Juzerun Steel Co., Ltd.- Type:Steel Coil

- Standard:ASTM, AISI, GB, JIS, DIN, BS

- Certification:ISO, RoHS, IBR

- Surface Treatment:Milling

- Technique:Cold Rolled

- Application:Ship Plate, Boiler Plate

Base Info

- Model NO.:200 300 400 Series

- Special Use:Measuring Tools, Cutters in Common Steel

- Stock:Stock

- Model No.:310

- Surface:2b,Ba,No.4,Mill Edge,Slit Edge

- Shape:Sheet, Coils,Strips

- Thickness:0.3~180mm Thickness

- Package:Standard Sea Packaging or as Required

- Delivery:Within 15 Days After Receiving The Deposit

- Process:Cold , Hot Rolled

- Transport Package:Standard Sea Packaging

- Specification:Customized

- Trademark:OEM

- Origin:China

- HS Code:72209000

- Production Capacity:500 Ton, Month

Description

Basic Info.

Model NO. 200 300 400 Series Special Use Measuring Tools, Cutters in Common Steel Stock Stock Model No. 310 Surface 2b/Ba/No.4/Mill Edge/Slit Edge Shape Sheet/ Coils/Strips Thickness 0.3~180mm Thickness Package Standard Sea Packaging or as Required Delivery Within 15 Days After Receiving The Deposit Process Cold / Hot Rolled Transport Package Standard Sea Packaging Specification Customized Trademark OEM Origin China HS Code 72209000 Production Capacity 500 Ton/ MonthProduct Description

Product Description

High Quality hot sale AISI SUS 430 321 309S 904L 420 310S 201 316L 304 Stainless Steel Coil

304/301/316/321/430 /420 /410/6Cr13/1.4116 0.2mm thick best price and quality stainless steel coil/sheet/strip/plate

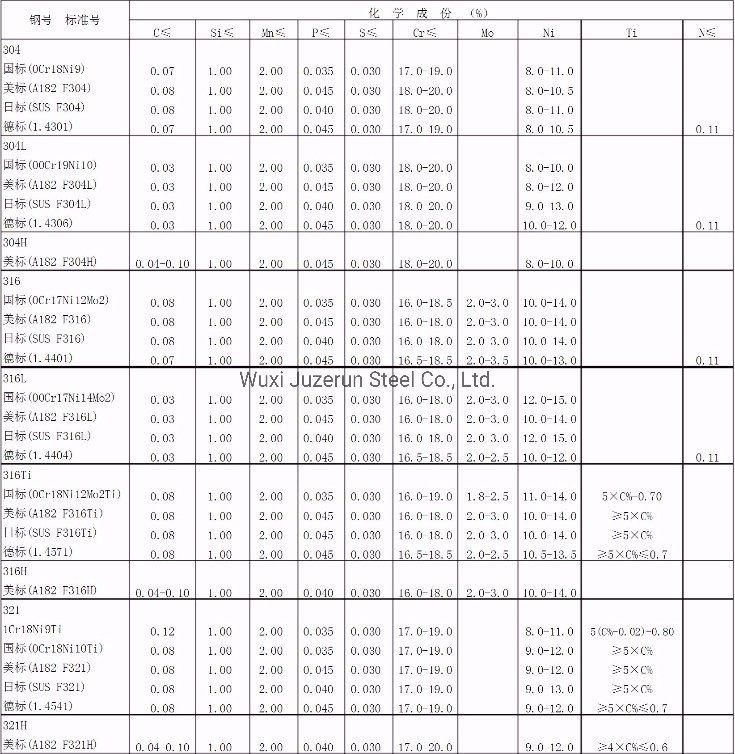

Standard | AISI,ASTM,DIN,GB,JIS,BS,EN |

Material | SPCC,SPCD,SPCE,ST12-15,DC01-06,Q195A-Q235A,Q195AF-Q235AF, Q295A(B)-Q345A(B) |

Thickness | 0.13-2.5mm |

Width | 30-1500mm |

Normal width | 750mm,914mm,1000mm,1219mm,1250mm,1500mm |

Length | According to customer's requirement or cut into sheet |

Tolerance | Thickness:+/- 0.02mm Width:+/-0.02mm |

Coil ID | 508mm,610mm |

Coil Weight | 3-13 tons |

Production capacity | 500 tons per month |

Surface treatment | Oil/dry/ passivation /pickling |

Application | Galvanized Steel, PPGI, Door, Household Appliance, Machine, |

| Item | Surface Finishing | Surface finishing methods | Main Applications |

| NO.1 | HR | Heat treatment after hot rolling, pickling, or with treatment | For without the purpose of the surface gloss |

| NO.2D | Without the SPM | Method of heat treatment after cold rolling, pickling surface roller with wool or eventually a light rolling a matte surface processing | General materials,building materials. |

| BA | Bright annealed | Bright heat treatment after cold rolling , in order to be more shiny, cold light effect | Automotive parts, home appliances, vehicles, medical equipment, food equipment |

| NO.3 | Shiny, coarse grain processing | The NO.2D or NO.2B processing timber No. 100-120 polishing abrasive grinding belt | Building materials, kitchen supplies |

| NO.4 | After CPL | The NO.2D or NO.2B processing timber No. 150-180 polishing abrasive grinding belt | Building materials, kitchen supplies, vehicles, medical and food equipment |

| 240# | Grinding of fine lines | The NO.2D or NO.2B processing timber 240 polishing abrasive grinding belt | Kitchen appliances |

| 320# | More than 240 lines of grinding | The NO.2D or NO.2B processing timber 320 polishing abrasive grinding belt | Kitchen appliances |

| 400# | Close to BA luster | The MO.2B timber 400 polishing wheel polishing method | Building materials, kitchen utensils |

| HL(hair lines) | Polishing line having a long continuous processing | In a suitable size ( usually mostly No. 150-240 grit ) abrasive tape for as long as the hair, having a continuous processing method of polishing line | The most common building materials processing |

| NO.6 | NO.4 processing less than the reflection , the extinction | NO.4 processing material used for polishing Tampico brushing | Building materials, decorative |

| NO.7 | Highly accurate reflectance mirror processing | No. 600 of the rotary buff with a polishing | Building materials, decorative |

| NO.8 | Highest reflectivity mirror finish | Fine particles of abrasive material in order polishing , mirror polishing with a polishing | Building materials, decorative, mirrors |

Application

Packaging and delivery

Related Products

Factory

FAQ

1. How long can make delivery?

For stock products, will make shipments in 5- 7 days after receiving deposit or receiving L/C; for products need new production for common materials, usually make shipments in 15-20 days; for products need new production for special and rare materials, usually need 30-40 days to make shipment.

2. Will the Test Certificate be certified to EN10204 3.1?

For the new production products no need furthur cutting or processing, will provide the Original Mill Test Certificate certified to EN10204 3.1; for the stock products and the products need cutting or furthur processing, will issue Certificate of Quality on our Company, It will show the original mill name and the riginal datas.

3. Once the received products found not comply with the products the contract demands, what will you do?

Once the received products found not comply with the products the contract lists, when receiving the pictures and the official documents and data from your side, if it is proved not comply, we will compensate the loss at first time.