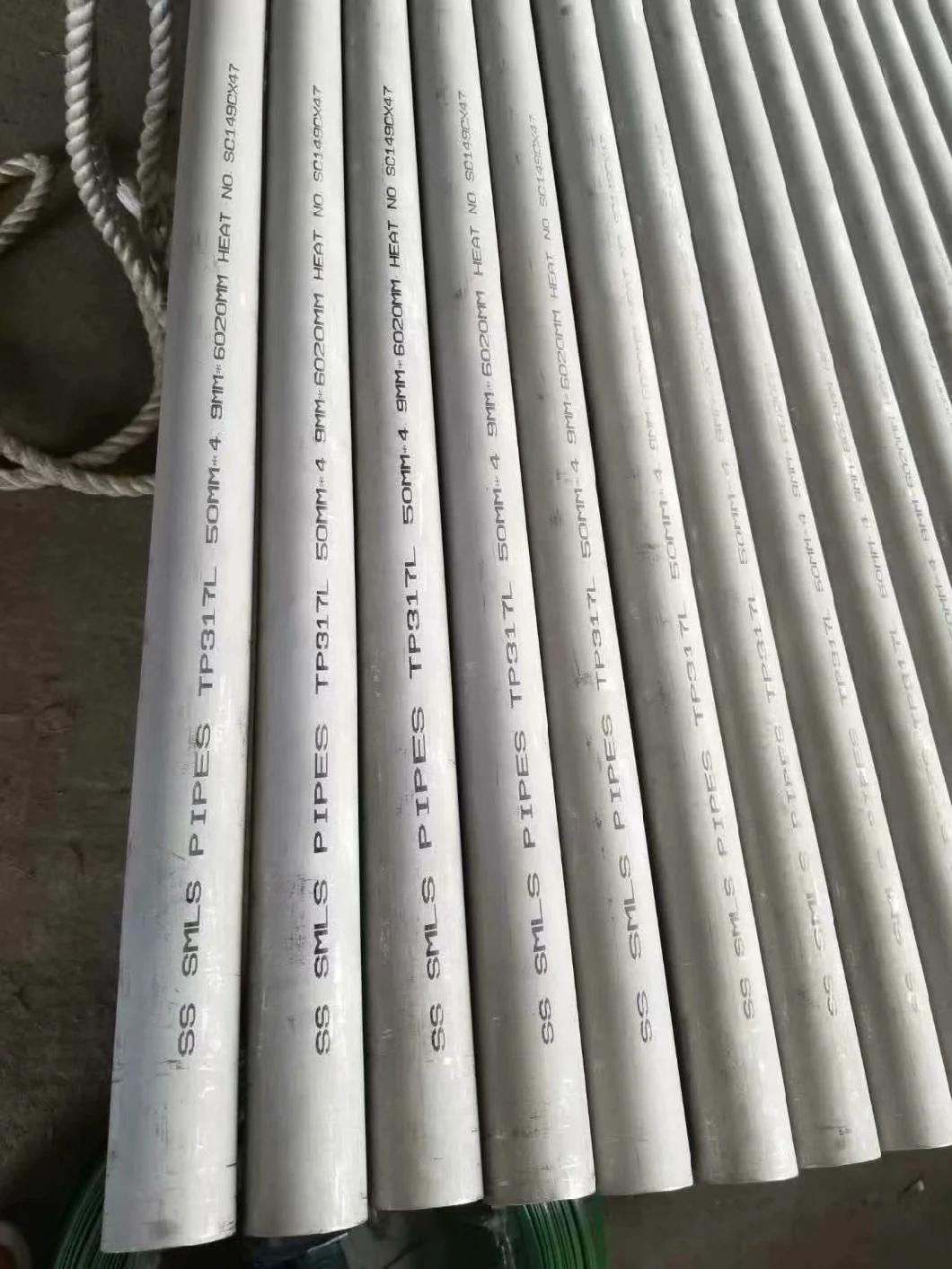

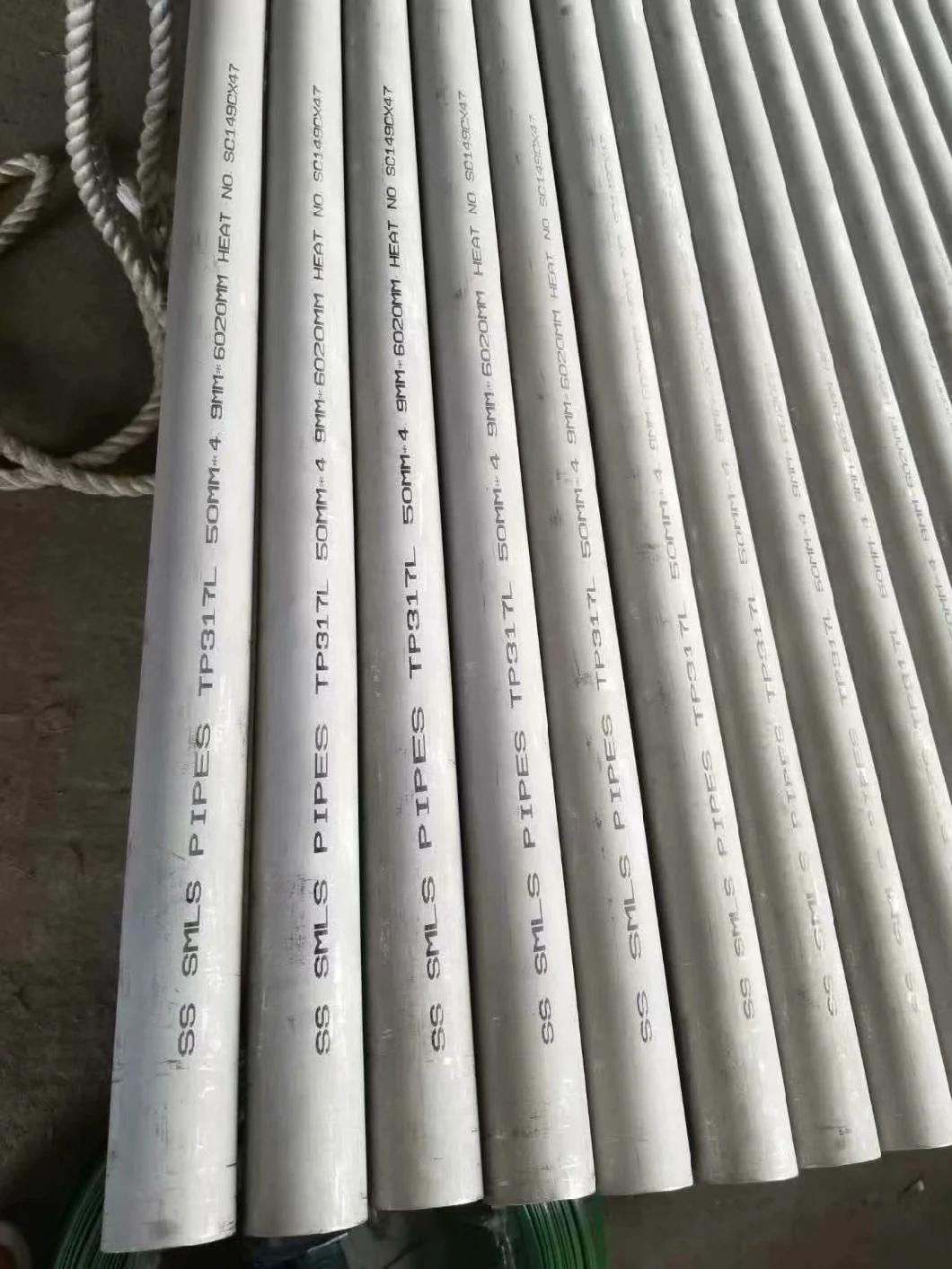

Seamless Stainless Steel Pipe ASTM A312 Tp317L

Guangzhou Kingmetal Steel Industry Co., Ltd.- Type:Seamless

- Technique:Cold Drawn

- Material:Stainless Steel

- Surface Treatment:Piackling

- Usage:Pipeline Transport, Hydraulic,Automobile Pipe, Machinery Industry, Chemical Industry

- Section Shape:Round

Base Info

- Model NO.:EL-SP

- Grade:310S, 309S, 316, 316L, 321, 317, 317L, 347, 304, 3

- Wt:1mm-60mm

- Length:1-12m

- Head Code:Round

- Delivery Time:15-30 Days After Down Payment

- Seocnd or Non Second:Non Second

- Standard or Non Standard:Standard

- Payment:Fob, CNF, CIF, Fca, etc.

- Brand:Kingmetal

- Transport Package:Bundle & Seaworthy

- Specification:6mm-630mm

- Trademark:Kingmetal

- Origin:China (Mainland)

- HS Code:7307290000

- Production Capacity:20000 Tons ,Month

Description

OD(6mm-530mm ) x WT(SCH10s-SCH160s) x L(12m max)Material Grade

304,304L,316,316L,321,347,317L,310S,201,202,409,410 etc

Standard

ASTM A312, A269,A249,A270,A554,A269,etc

Description

Surface Finish

Treatment : Annealing and Pickling, Matt Finish or Satin Finish

Mirror Finish, Wire Drawing or Hairline Finish

Roughness Average : 0.1~0.2μm Outside, 0.3~0.4μm Inside.

Ends Finish

Plain Ends or Beveled Ends

Test

Eddy Current/ Hydrostatic/ Ultrasonic/ Intergranular Corrosion

Or according to customers' request

ApplicationFor use in the Petroleum, Chemical, Chemical fiber, Medical Machinery, Aerospace, Paper, Food, Shipbuilding, Environmental Protection, Boilers, Heat Exchangers, Pressure Vessels, Condensers, Water, Electricity and other industries.

PackingEach in PVC bags, Bundles with knitted plastic bags, Wooden cases,Wooden pallet or according to customers' request

304,304L,316,316L,321,347,317L,310S,201,202,409,410 etc

Standard

ASTM A312, A269,A249,A270,A554,A269,etc

Description

Surface Finish

Treatment : Annealing and Pickling, Matt Finish or Satin Finish

Mirror Finish, Wire Drawing or Hairline Finish

Roughness Average : 0.1~0.2μm Outside, 0.3~0.4μm Inside.

Ends Finish

Plain Ends or Beveled Ends

Test

Eddy Current/ Hydrostatic/ Ultrasonic/ Intergranular Corrosion

Or according to customers' request

Application

Packing

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

904L | 0.02 | 1.0 | 2.00 | 0.045 | 0.03 | 23.00-28.00 | 19.00-23.00 |