AISI 12L14 Cold Drawn Hexagonal Steel (UNS G12144) / 12L14 Properties

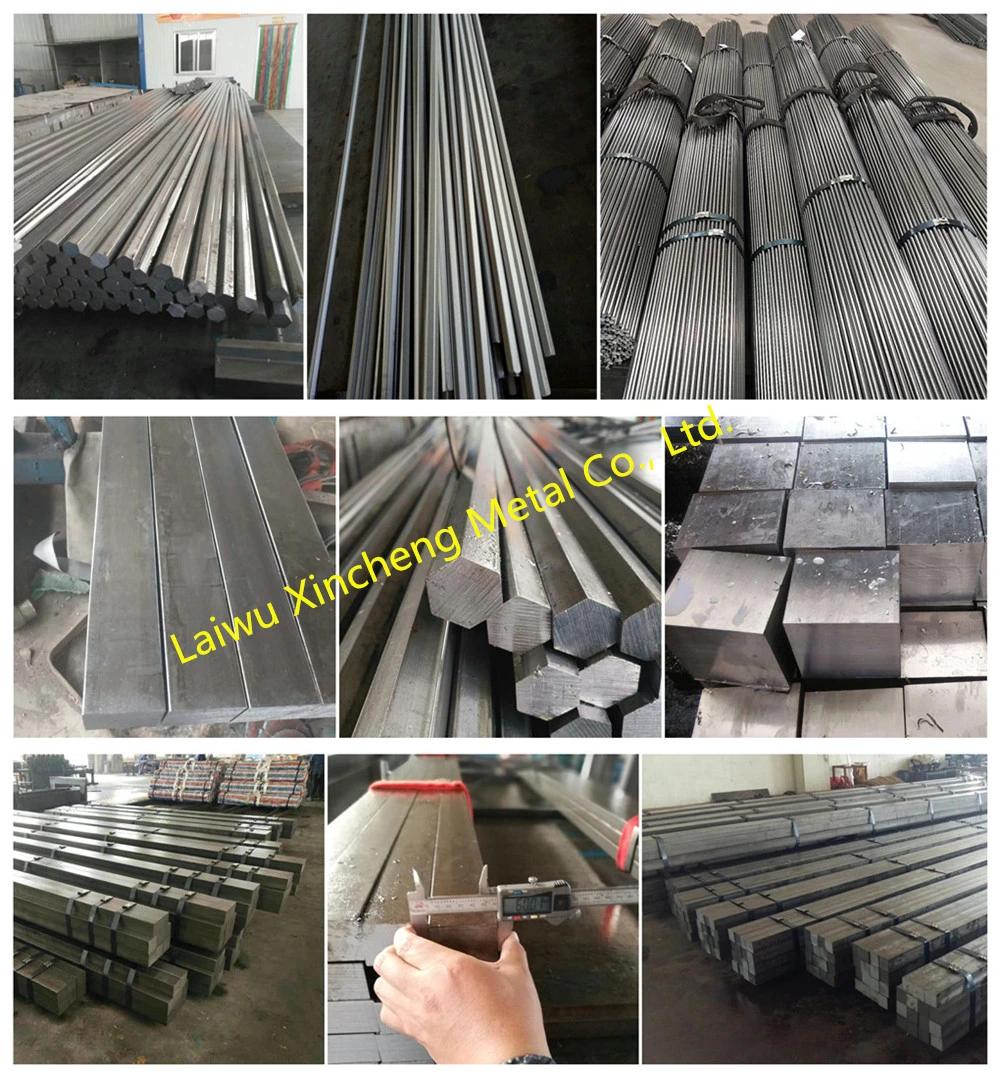

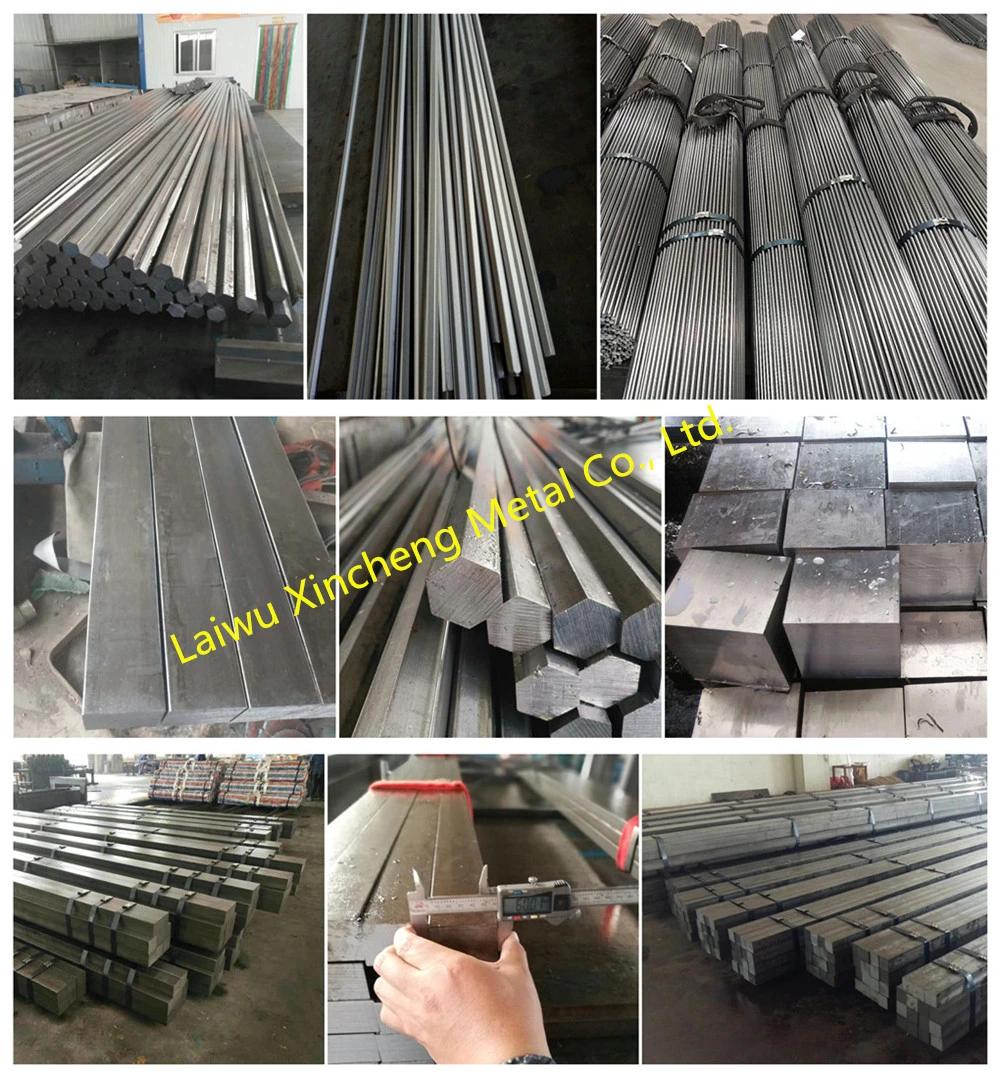

Laiwu Xincheng Metal Co., Ltd.- Standard:AISI, JIS, ASTM, DIN, BS, GB

- Certification:UL, ABS, RoHS

- Technique:Cold Drawn

- Surface Treatment:Bright

- Alloy:Non-alloy

- Grade:12L14, Free Cutting Steel

Base Info

- Model NO.:AISI 12L14

- Composition:Lead Steel

- Straightness:0.2mm,M

- Length:as Required

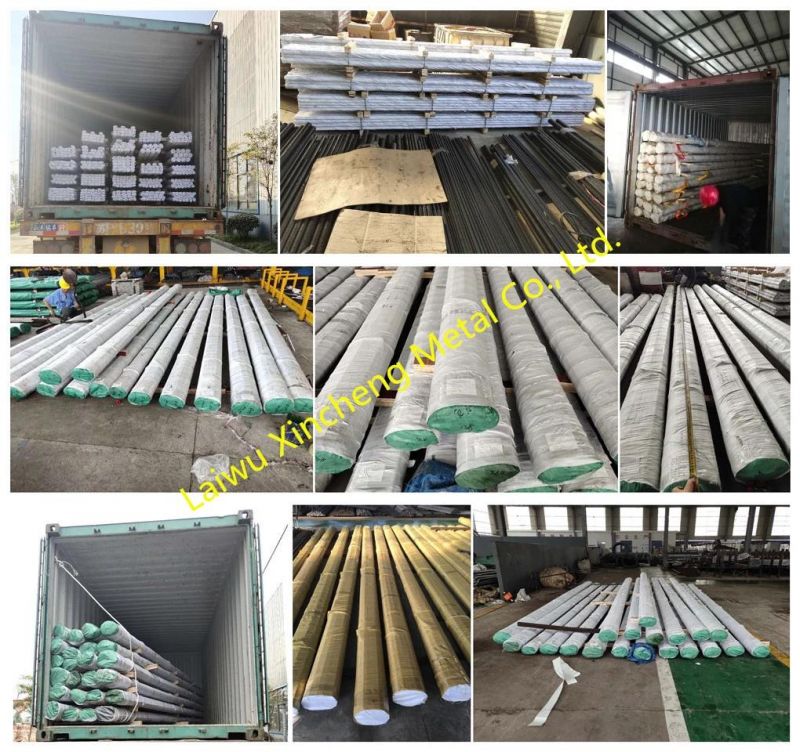

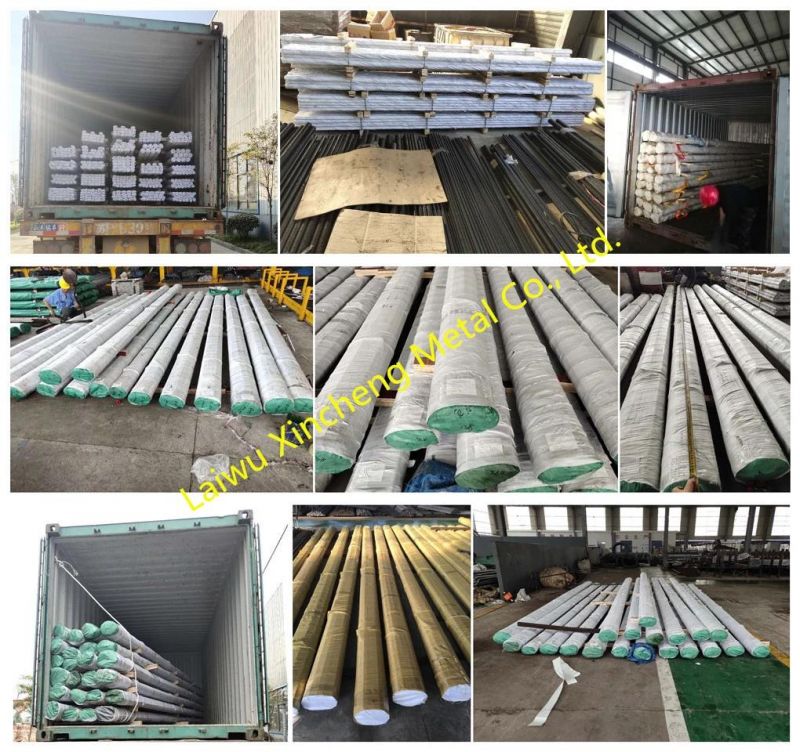

- Transport Package:Anti-Rust Packing

- Specification:0.5mm-100mm

- Origin:China

- Production Capacity:3000tons,Month

Description

1 to 3-0.025 -0.04 -0.06 (-0.00098") (-0.00158") (-0.00236") Over 3 to 6 -0.03 -0.048 -0.075 (-0.00118") (-0.00189") (-0.00295") Over 6 to 10 -0.036 -0.058 -0.09 (-0.00142") (-0.00228") (-0.00354") Over 10 to 18 -0.043 -0.07 -0.11 (-0.00169") (-0.00275") (-0.00433") Over 18 to 30 -0.052 -0.084 -0.13 (-0.00205") (-0.00331") (-0.00512") Over 30 to 50 -0.062 -0.1 -0.16 (-0.00244") (-0.00393") (-0.00630") Over 50 to 80 -0.074 -0.12 -0.19 (-0.00291") (-0.00472") (-0.00748") Over 80 to 120 -0.087 -0.14 -0.22 (-0.00343") (-0.00551") (-0.00866")

4.Starightness:1mm/m (max)

5.Delivery time: usually 7-15 days for stock items, and 30 days for new production

6.Packing: anti-rust good export packing

7.1214 property (hot rolled), For eg

7.1214 property (Cold drawn), For eg

We company have good QC inspection tear and full set of inspect equipment including: UT test machine, Tensile testing machine,Hardness testing machine,Dimensional measuring instrument,f,spectrometer,Metallographic microscope and so on, so that we can always supply good mateterials for various projects and industries , if you have any need for our producrs,please contact us freely

4.Starightness:1mm/m (max)

5.Delivery time: usually 7-15 days for stock items, and 30 days for new production

6.Packing: anti-rust good export packing

7.1214 property (hot rolled), For eg

| Thickness [mm] >16 - 40 |

| 0,2% proof stress Rp0,2 [N/mm²] min. 200 |

| Tensile strength Rm [N/mm²] min. 380 |

| Hardness [HB] min. 113 |

7.1214 property (Cold drawn), For eg

| Condition of delivery: Cold drawn |

| Thickness [mm] >16 - 40 |

| 0,2% proof stress Rp0,2 [N/mm²] min. 375 |

| Tensile strength Rm [N/mm²] min. 470 |

| Hardness [HB] min. 139 |