1.2311 1.2312 P20+S Tool Steel Flat Module Steel Plate Bar

Guangzhou Changfeng Steel Co., Ltd.- Technique:Hot Rolled

- Standard:AISI, JIS, ASTM, DIN, BS, GB

- Certification:RoHS

- Production process:EF,EAF+LF+VD,ESR

- Technology:hot rolled,forged

- Heat Treatment:Q+T

Base Info

- Surface:Black

- Payment term:TT,LC

- Delivery Time:15-20days

- Transport Package:Standard,Customized

- Specification:standard,customized

- Trademark:Baosteel

- Origin:China

- HS Code:7225401000

- Production Capacity:1000 Tons, Month

Description

Basic Info.

Surface Black Payment term TT/LC Delivery Time 15-20days Transport Package Standard/Customized Specification standard/customized Trademark Baosteel Origin China HS Code 7225401000 Production Capacity 1000 Tons/ MonthProduct Description

1.2312 P20+S alloy mould/die steel flat bar1.2312/P20+S steel is ideally suited for the production of moulds where improved machinability is required. Typical applications include die holders, zinc die casting dies, backers, bolsters and injection moulds. The versatility of this plastic mould tool steel with its high tensile characteristics enables uses for a variety of other applications such as shafts and wear strips.

1. The main performance

It has excellent hardening depth and good machinability, Delivery to pre hardened and tempered condition, Sulfur content is higher than 1.2311. Can impose nitriding processing (about 800HV), plating Nickel or chrome.

2. Application:

Mainly used for the degree of thefamily which do not require extreme large plastic moulds, Used as a low melting point of die holder , mould base, etc.

3. Grade

| W.Nr | DIN | AFNOR | AISI/SAE | GB |

| 1.2312 | X40CrMnMoS8-6 | (40CMD8S) | P20+S | 4Cr2MnMo |

4. Chemical composition (%)

| C | Mn | Si | Cr | Mo | S | P |

| 0.35-0.45 | 1.40-1.60 | 0.30-0.50 | 1.80-2.10 | 0.15-0.25 | 0.05-0.10 | ≤0.030 |

5. Phase transition temperature

| Ac1 | 740°C |

| Ms | 310°C |

6. The hardness of delivery

| Prehardened and tempered | HB278-325(950-1100N/mm²) |

7. Heat treatment

| Annealing | 1)Heated to720-750°C,Two to four hours heat preservation, 2)Furnace cooling |

| Stress relief | 1)Heated to560-650°C and then two to four hours heat preservation 2)Furnace cooling or air cooling |

| Pre hardened | 1)Preheat to 600-650°C 2)Heated to hardening temperature 840-840°C and heat preservation 3)Oil cooling 4)Hardness:HRC51 |

| Drawing temper | 1)Immediately after quenching 2)When the 580-650°C,with the 1/inch to heat preservation |

8. Delivery: For abundant stock, 15-20 days.For customized products, 30-50 days.

9. Packing: We provide standard export packing or according to customers' request.

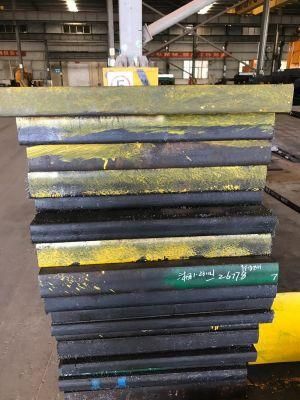

Product show