Special Shaped Stainless Steel Pipe for Railing

Foshan Hot Chance Metallic Material Co., Ltd.- Type:Welded

- Technique:Cold Rolled

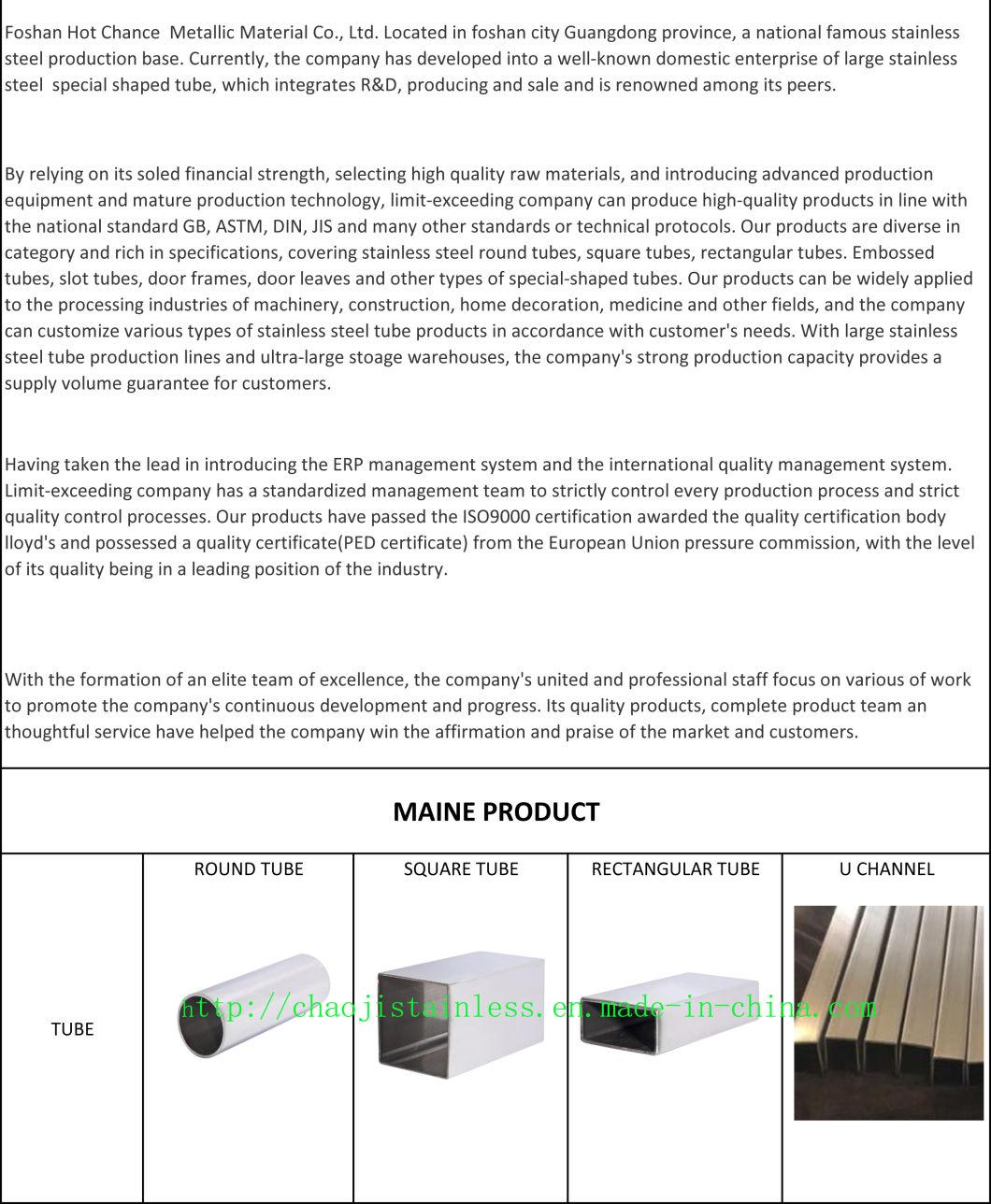

- Material:201, 304, 316

- Surface Treatment:Satin, Hairline

- Usage:Pipeline Transport, Machinery Industry, Decortation

- Section Shape:40*80

Base Info

- Model NO.:51*72mm

- 201ni%:>1%

- 304ni%:>8%

- 316ni%:>10%

- 201c%:<0.1%

- 304 316 C%:<0.08%

- 304L 316L C%:<0.03%

- 316,316L Mo %:2-3%

- Thickness Tolerance:-0.05,+0.05mm

- Diameter Tolerance:-0.02,+0.02mm

- Length Tolerance:-0.5mm,+0.5mm

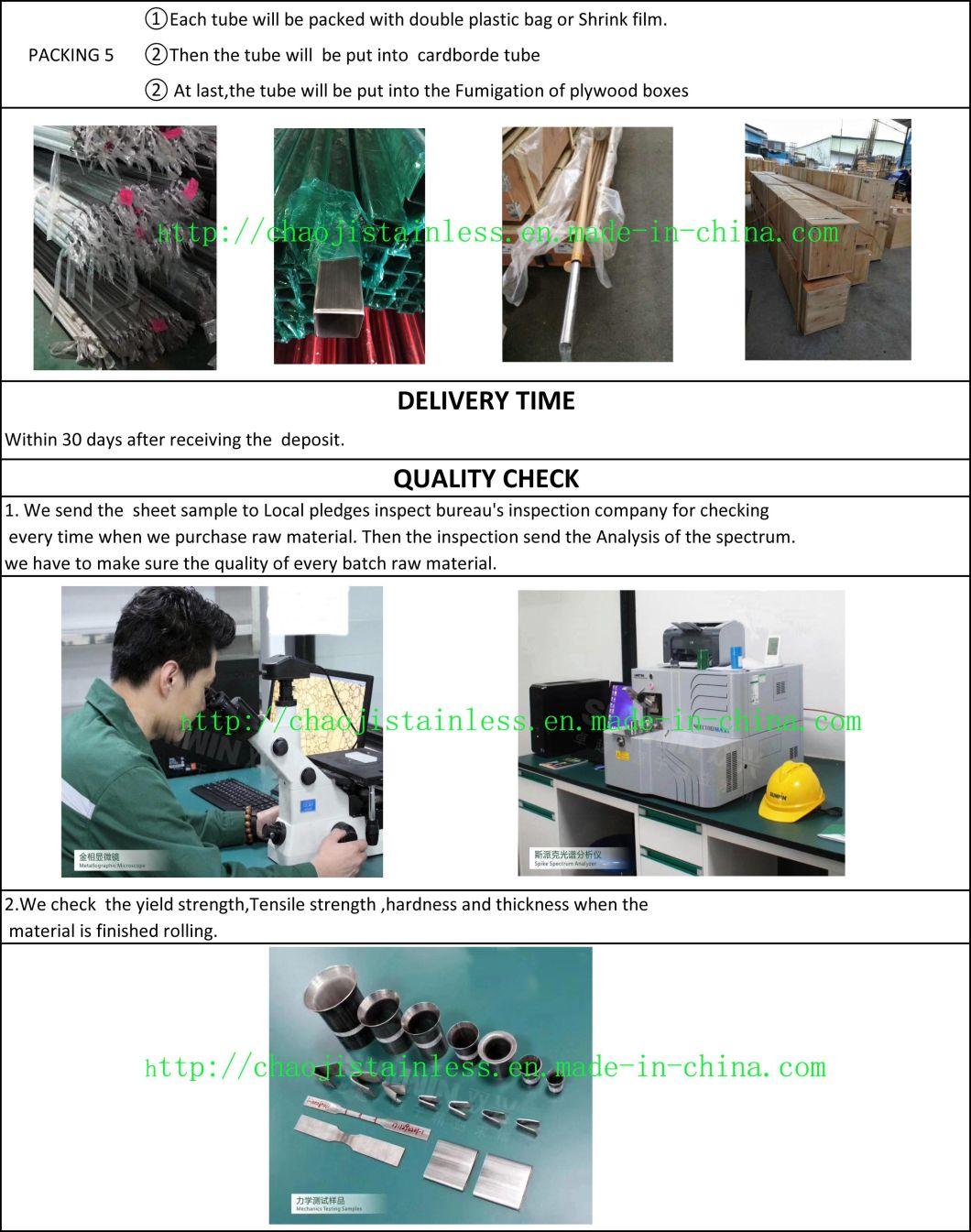

- Transport Package:Seaworthy Packing

- Specification:diameter: 38.1-76.2mm

- Trademark:chaoji

- Origin:China

- HS Code:730640000

- Production Capacity:1000tons,Month

Description

Basic Info.

Model NO. 51*72mm 201ni% >1% 304ni% >8% 316ni% >10% 201c% <0.1% 304 316 C% <0.08% 304L 316L C% <0.03% 316,316L Mo % 2-3% Thickness Tolerance -0.05/+0.05mm Diameter Tolerance -0.02/+0.02mm Length Tolerance -0.5mm/+0.5mm Transport Package Seaworthy Packing Specification diameter: 38.1-76.2mm Trademark chaoji Origin China HS Code 730640000 Production Capacity 1000tons/MonthProduct Description

FAQ

FAQ1. What is your major market?

90% of our tubes are exported . We mainly sell to Southeast Asia, Europe and Australia

We sell to the countries like Thailand ,India,Vietnam ,Indonesia ,Malaysia ,German,Poland, Italy,Australia.

2. What is your location?

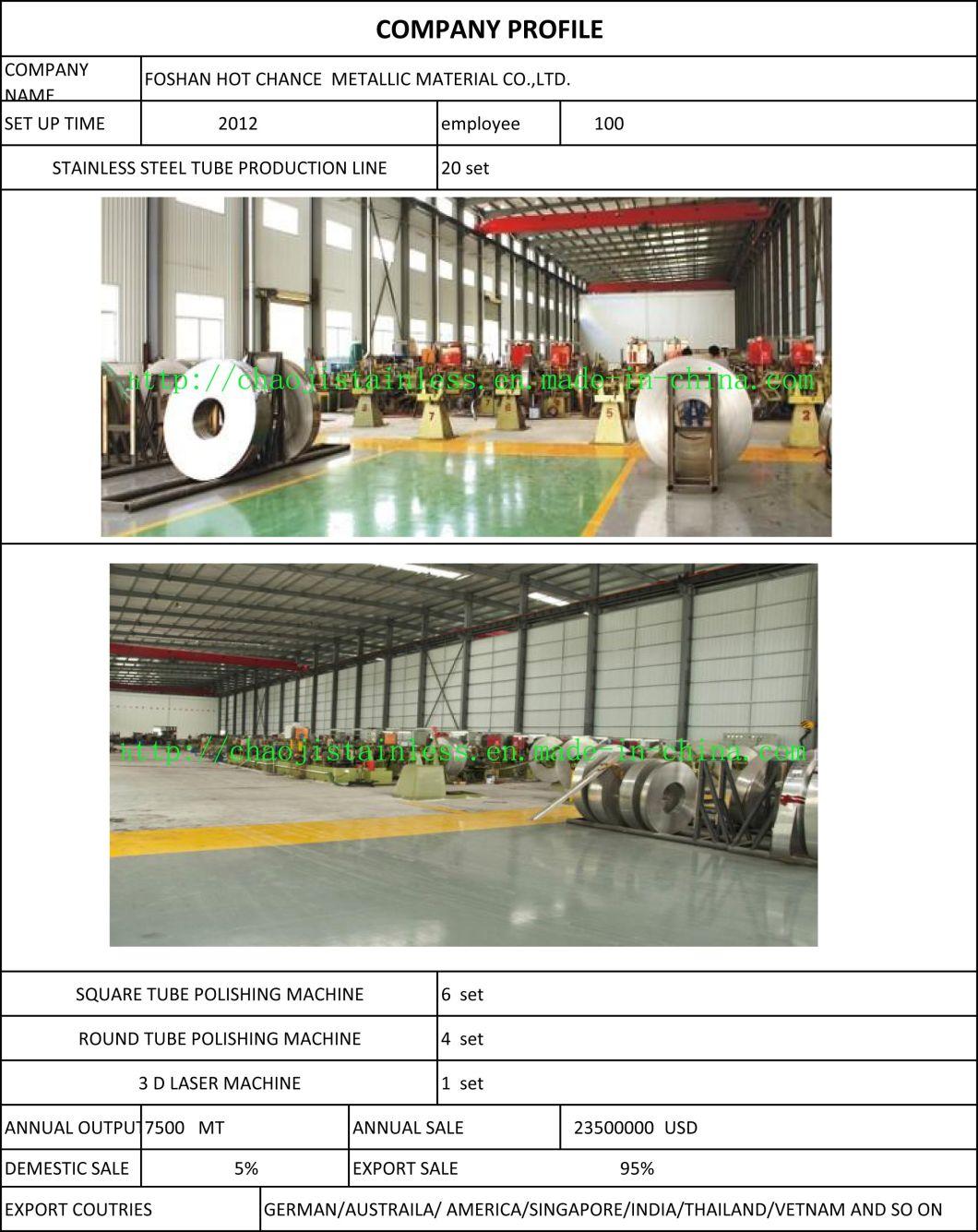

We are located in Foshan City which is a famous stainless steel production base.

Our new workshop is located in Sanshui District, Foshan City.

3.What's the annual output?

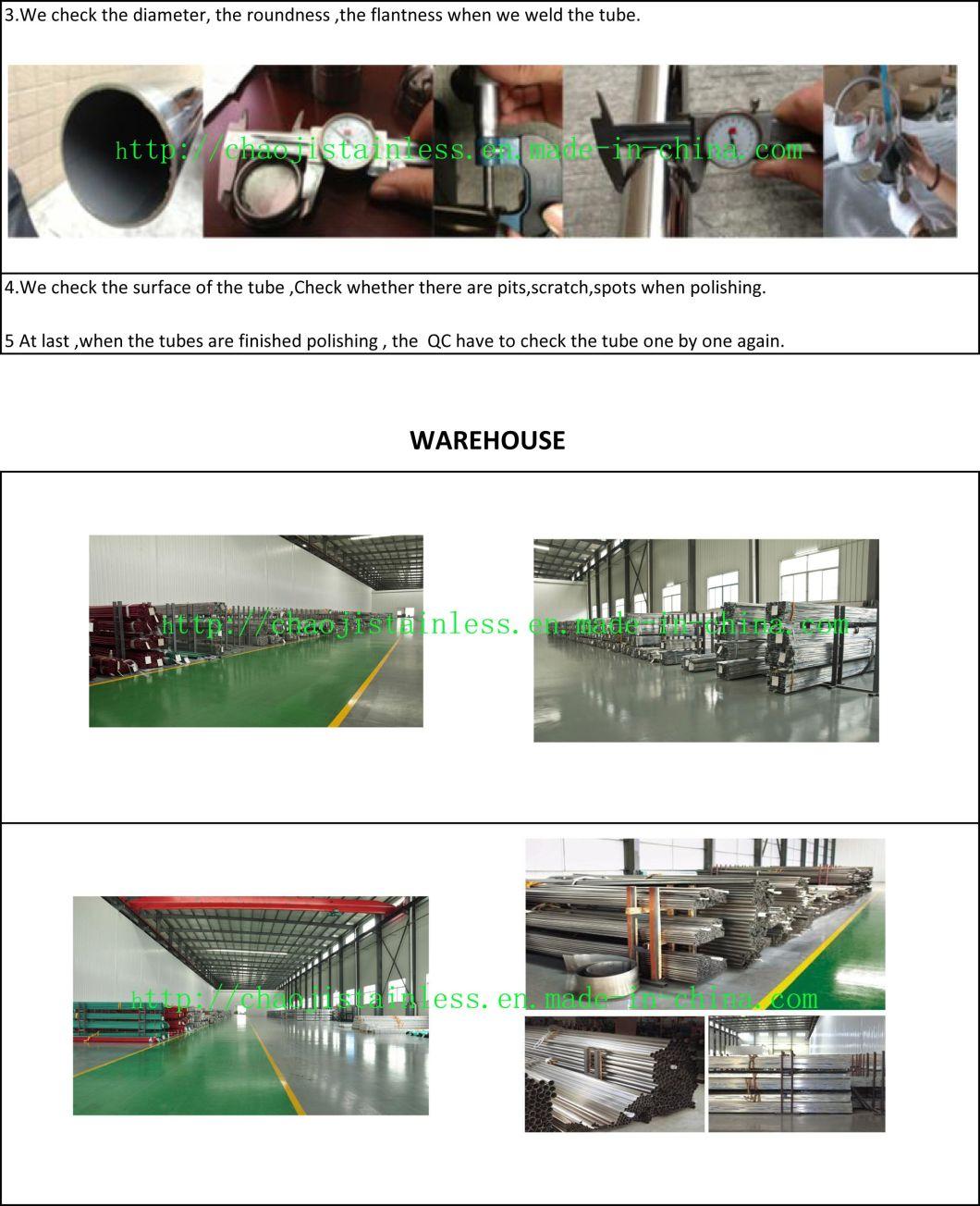

We produce more than 25000 tons stainless steel tubes in a year.

4. What is your welding method?

All of our tubes are welded by tig welding methods. Our tubes can get fully welding and smooth inner welding, without blisters, leak welding or black line. All of our tube are good for tube bending.

5. How do you control the quality during the polishing process?

1)As for the mirror polish square/rectangular tube , we will polish it as least four times)

2)During the polishing processing, we set a special sanding wheel to polish the welding part.

3)To avoid scratches,after polishing,the tubes will be lay out on a steel crate then we could lift the whole steel crate instead of the tube.

4)On the other hand, we use the gunny bags to protect the tube's surface when the tube laying-out.

6. How do you inspect the tubes?

The Quality inspectors inspect the tubes during each production processes from raw material,tube welding,polishing,packaging.

1) Before the production of each machine, we will have the first checked and record the data.

2)During the production, our inspector and engineer have been carefully modifying treatment and we record the data every two hours.