Good Wear Resistance Mould Steel (SKD12, A8, 1.2631, O1)

Guangzhou Changfeng Steel Co., Ltd.- Type:Alloy Steel Bar

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Technique:Hot Rolled

- Application:Tool Steel Bar, Die Steel Bar

- Surface Treatment:Polished

- Alloy:Alloy

Base Info

- Model NO.:SKD12, A8, 1.2631, O1

- Special Use:Mold Steel

- Grade Number:SKD12, A8, 1.2631,O1

- Dimensions:25-800mm

- Length:250mm-6000mm

- Test:SGS,Ut 100%,Element Testing

- Heat Treatment:Annealing,Q+T

- Certificate:ISO ,Mill Certificate

- Delivery Quatity:Include MOQ

- Payment:30%Deposit,Blance by L,C at Sight or T,T

- Transport Package:Standard Packing

- Specification:According to customer requirements

- Trademark:CF STEEL

- Origin:China

- HS Code:7225401000

- Production Capacity:1000t,Month

Description

Basic Info.

Model NO. SKD12, A8, 1.2631, O1 Special Use Mold Steel Grade Number SKD12, A8, 1.2631,O1 Dimensions 25-800mm Length 250mm-6000mm Test SGS/Ut 100%/Element Testing Heat Treatment Annealing/Q+T Certificate ISO /Mill Certificate Delivery Quatity Include MOQ Payment 30%Deposit,Blance by L/C at Sight or T/T Transport Package Standard Packing Specification According to customer requirements Trademark CF STEEL Origin China HS Code 7225401000 Production Capacity 1000t/MonthProduct Description

SKD12 high grade cold work mould steelStandard:JIS G4404:2000

Similar grade:A2, BA2, 2231Z100CDV5

Heat treatment hardness:58-61HRC

Introduction:

SKD12 case of air quenching tool steel with deep air-hardening properties, which requires tempering after quenching quenching and tempering must maintain its complex shape of the mold is extremely useful.

The air quenching of steel due to the deformation caused by manganese-based oil is only about 1/4 of quenching tool steel, the wear resistance between manganese oxide and high carbon high chromium tool steel, toughness better than any one particular It requires suitable for good wear resistance but also has good toughness, special tools, widely used in die cutting and forming dies, roll, punch, rolling dies and thread rolling dies, but also for certain types of scissors sheet.

Features:

1.This is alloy mould steel with medium Alloy content ,due to contain molybdenum and vanadium, so that it has good hardenability,

2.SKD12 Steel has good impact toughness and good wear resistance cause to uniform distribution of carbide,

3.Good Air quenching performance,

4.Small quenching deformation ,

5.Toughness is better than 9Mn2V,Cr12

6.Uniform and fine carbide, good wear resistance.

Advance:

1, air quenching mould steel has excellent air quenching hardening

2, good wear resistance performance

3, Micro deformation

4, High hardenability

5, High compressive strength

Heat treatment:

Annealing:1,800-850oC, slow cooling 2, Spheroidizing

Quenching:940-960oC, air cooling

Tempering:180-220oC, air cooling HRc=60-64 510-520oC, air cooing HRc=57-60

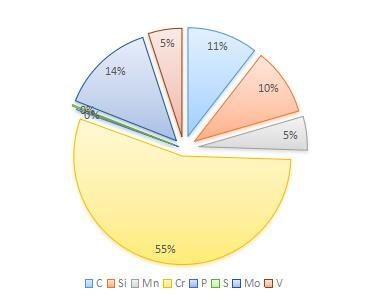

Chemical composition:

| C | Mn | Si | Cr | P | S | Mo | V |

| 0.95~1.05 | ≤1.00 | ≤0.50 | 4.75~5.50 | ≤0.025 | ≤0.020 | 0.90~1.40 | 0.15~0.50 |

Supply states:Spheroidizing HB≤230

Application:

Widely suitable for Large and complex for a variety of hardware die, and bear a greater impact load punch die.

1, For bending carbon content of 0.65% to 0.80% of the leaf spring that the hardness 37~42HRC, service life up to 11~12w times.

2, for bending carbon content of 0.65%~0.80%spring steel plate that the hardness 37~42HRC, and then add nitriding treatment, life expectancy of up to 40 million times.

3, The steel can be used for thread rolling die can be used for processing aluminum and copper alloys.

4, Stretch film, embossing dies, die cutting, stamping die.

Standard packing: