S235jr St37-2 Ss400 A36 S235jr Q235 Cold Drawn Bright Round Steel Bar Shaft

Laiwu Xincheng Metal Co., Ltd.- Type:Carbon Steel Bar

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Technique:Peeled Bright Surface

- Application:Structural Steel Bar

- Surface Treatment:Peeled Bright Surface

- Alloy:Non-alloy

Base Info

- Model NO.:S235jr St37-2 SS400 A36 S235JR Q235

- Special Use:Mold Steel

- MOQ of Cold Drawn Steel Bars:2tons

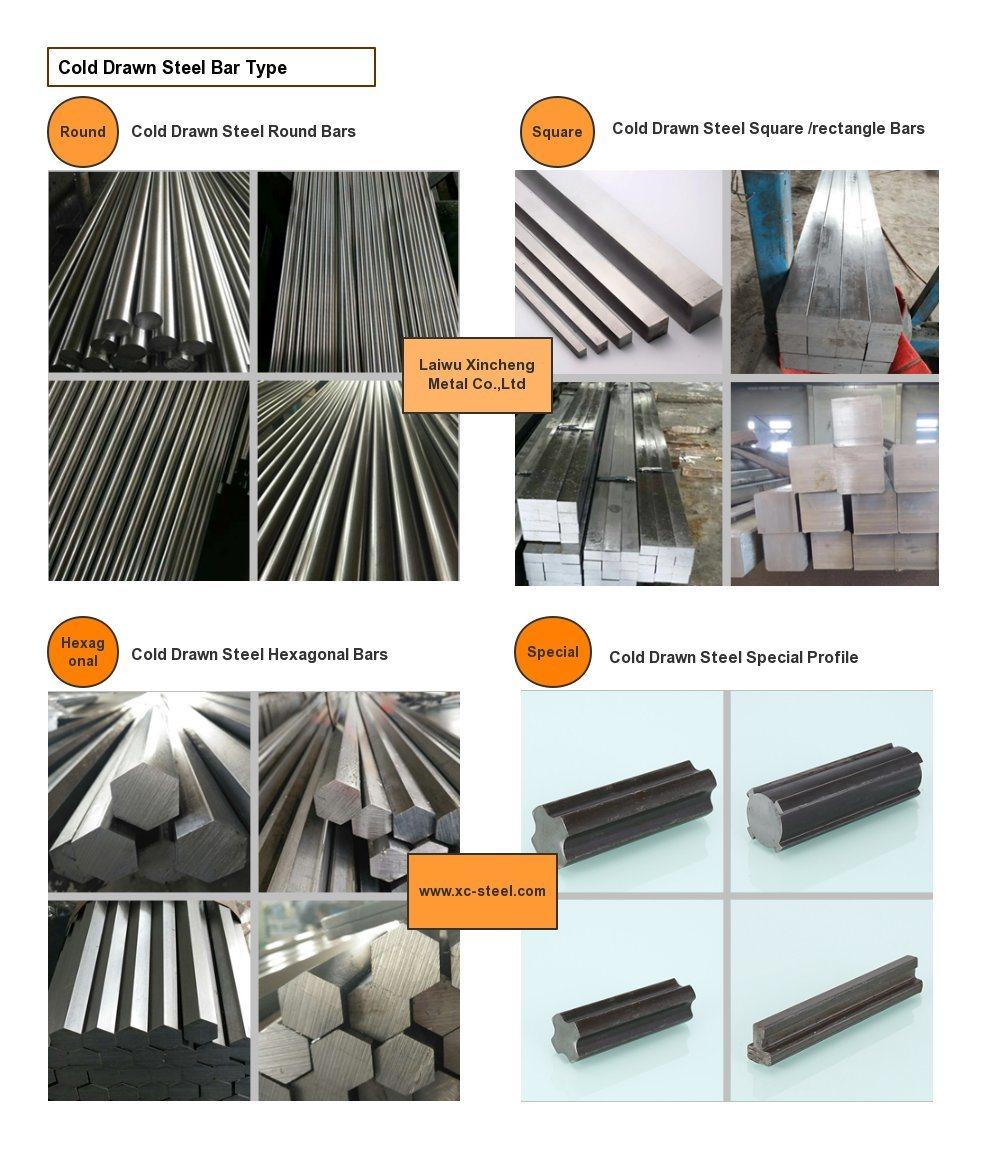

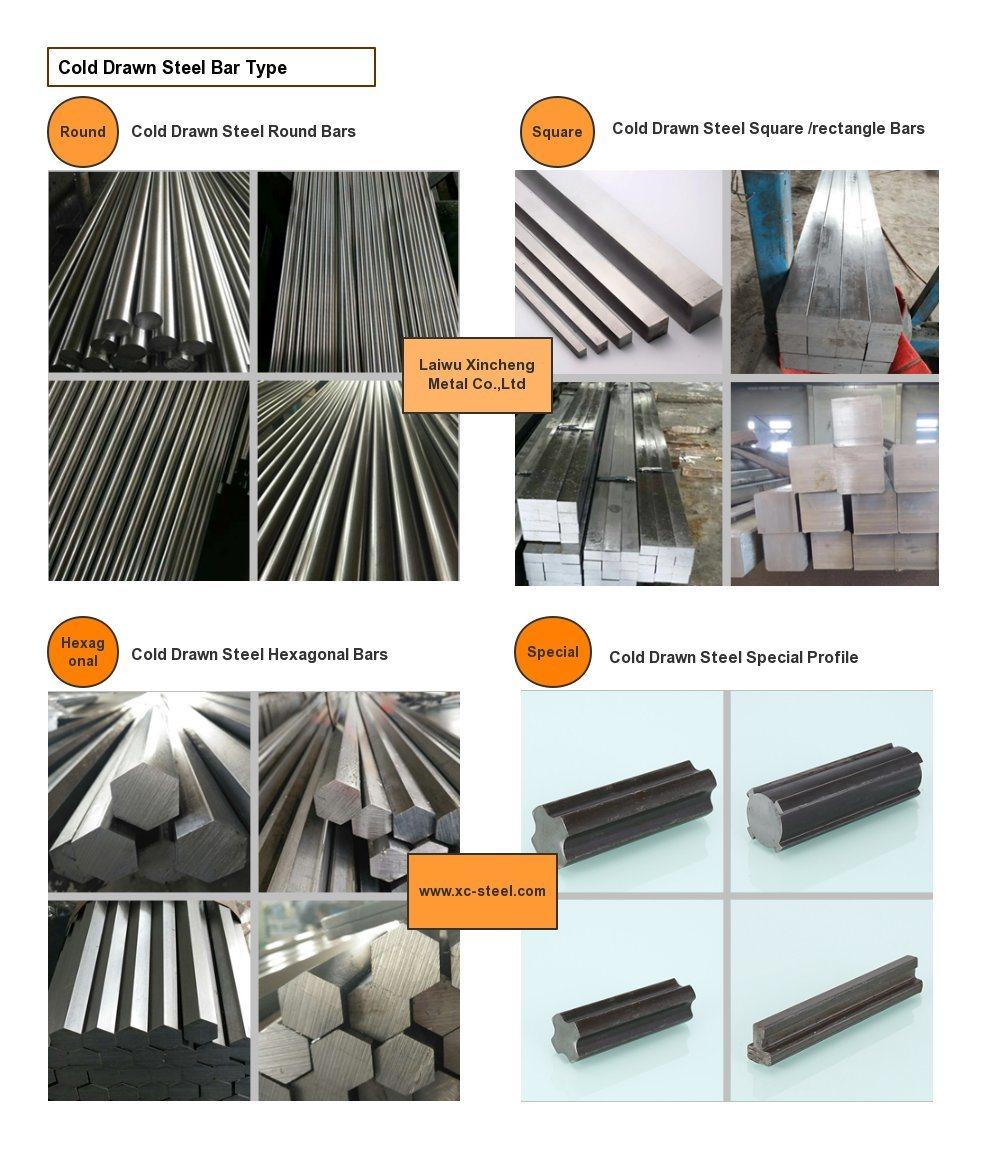

- Shape of Cold Drawn Steel Bars:Round, Square, Hexagonal, Special Profile

- Straughtness of Cold Drawn Steel Bars:Max 2mm,M

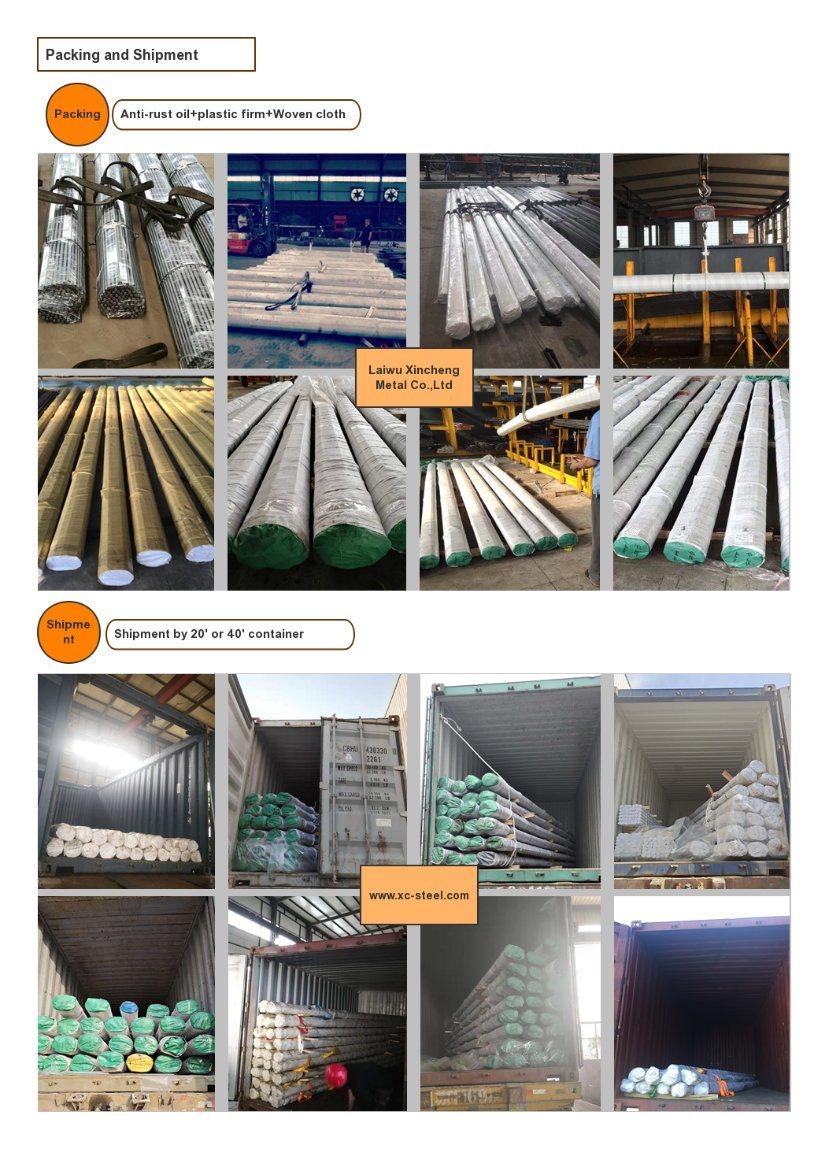

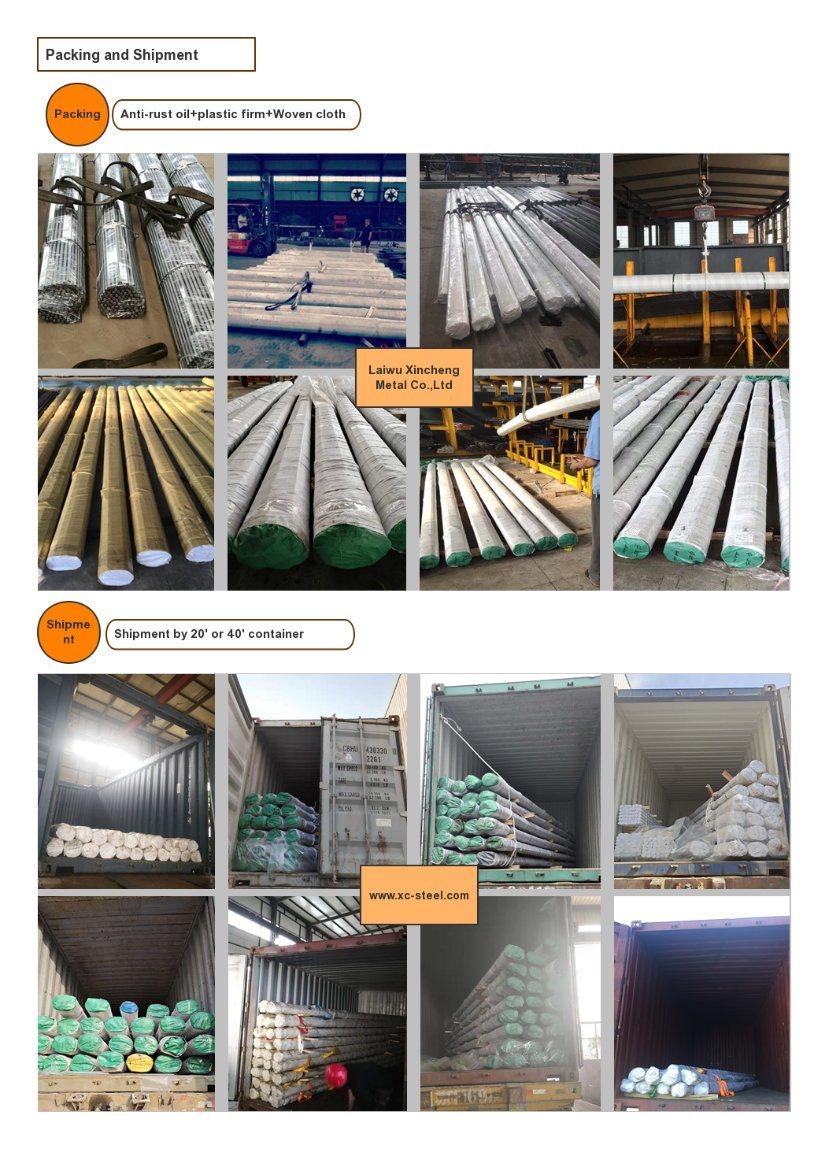

- Packing of Cold Drawn Steel Bars:Anti-Woven Cloth

- Transport Package:Anti-Rust Packing

- Specification:5mm to 100mm

- Trademark:Laiwu Xincheng

- Origin:China

- Production Capacity:3000tons,Month

Description

Chemical composition(%) C Si Mn S P GB/T 700 Q235A/B 0.22 0.35 1.4 0.05 0.045 JIS G3106 SS400B/SM400B 0.22 0.35 0.60-1.40 0.05 0.04 ASTM A573/A573M Grade 65 0.26 0.15-0.40 0.85-1.20 0.035 0.04 EN 10025-2 S235JR 0.2 1.4 0.035 0.035 ISO 630 E235B 0.22 0.05 0.05

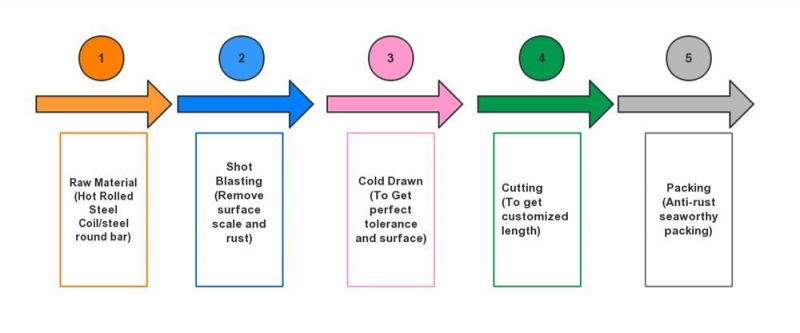

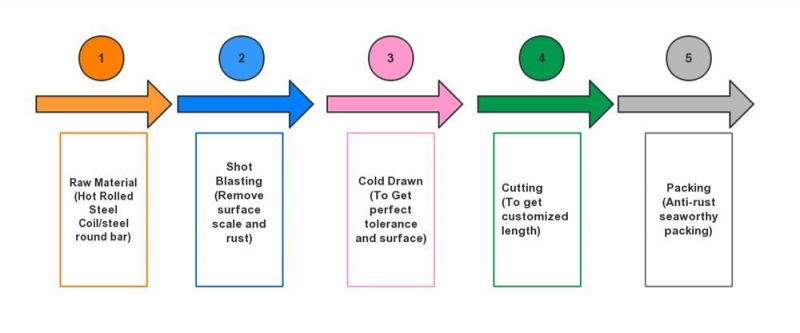

3.Processing of cold drawn steel bars:

EAF + LF + VD + CONCASTING BILLETS + HOT ROLLED + SHOT BLASTING +(ANNEALING) + COLD DRAWN + OILING + BUNDLING + BOTH ENDS CUTTING+ PACKING + MARKING

4.Application: hardware tools, auto parts, standard parts, fasteners common shaft, machinery manufacturing, light industry, hardware, bicycles, cars, motorcycles, textile machinery, transformers and other machinery industry

5.Advantages of cold drawn steel bars:

1.It can remove the Size and Section which provides Tighter tolerances which Reduces machining losses.

2.It can remove the Steel Surface Finish which Reduces surface machining & improves quality.

3.It can remove the Straightness which Facilitates automatic bar feeding in CNC.

4.It can increase the Mechanical Properties which Can reduce the need for hardening.

5.It can improve the Machinability and Productivity which Enables higher machining feeds, high tool life, yield & speeds and improved machined finish.

6.MOQ: 2tons per size

7.Straightness of cold drawn steel bars; max0.8mm/m

8.Packing: Rusty proof packages. Anti rusty oil painting, film wrapped inside and Nylon plastic bags wrapped outside

3.Processing of cold drawn steel bars:

EAF + LF + VD + CONCASTING BILLETS + HOT ROLLED + SHOT BLASTING +(ANNEALING) + COLD DRAWN + OILING + BUNDLING + BOTH ENDS CUTTING+ PACKING + MARKING

4.Application: hardware tools, auto parts, standard parts, fasteners common shaft, machinery manufacturing, light industry, hardware, bicycles, cars, motorcycles, textile machinery, transformers and other machinery industry

5.Advantages of cold drawn steel bars:

1.It can remove the Size and Section which provides Tighter tolerances which Reduces machining losses.

2.It can remove the Steel Surface Finish which Reduces surface machining & improves quality.

3.It can remove the Straightness which Facilitates automatic bar feeding in CNC.

4.It can increase the Mechanical Properties which Can reduce the need for hardening.

5.It can improve the Machinability and Productivity which Enables higher machining feeds, high tool life, yield & speeds and improved machined finish.

6.MOQ: 2tons per size

7.Straightness of cold drawn steel bars; max0.8mm/m

8.Packing: Rusty proof packages. Anti rusty oil painting, film wrapped inside and Nylon plastic bags wrapped outside