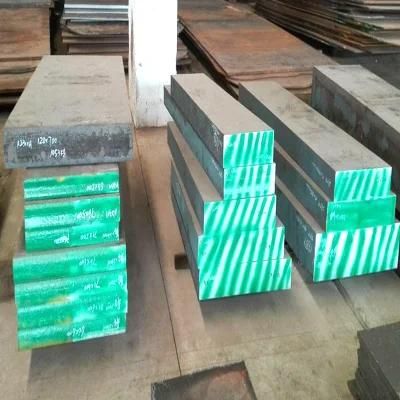

1.2311 P20 special Steel block & Plate & flat bar of Plastic injection mold

Guangzhou Changfeng Steel Co., Ltd.- Standard:DIN, JIS, AISI, ASTM, GB, BS

- Technics:Hot Rolled

- Application:Tool Steel Bar

- Surface:Black

- Alloy:Alloy

- Special Use:Wear Resistant Steel, Free Cutting Steel, Mold Steel

Base Info

- Model NO.:1.2311 P20 3Cr2Mo PDS-3

- Heat Treatment:Q+T

- Technique:Forged or Hot Rolled

- Thickness:10-460mm

- Width:155~2200mm

- Length:1600~10000mm

- Shape:Steel Plate,Flat Bar

- Test:SGS,Ut 100%,Element Testing

- Certification:ISO,Mill Certificate

- Delivery Quantity:Include MOQ

- Service:Sample free and 24 hours online

- Transport Package:Export Standard Packing or Customers′demand

- Specification:According to customer requirements

- Trademark:CF STEEL

- Origin:China

- HS Code:7225401000

- Production Capacity:1000 Mt, Month

Description

2. Application:

1. Used in zinc, aluminum,magnesium and its alloy die-casting mould.

2. Thermoplastic plastic injection molds,extrusion die.

3. Thermoplastic plastic blow molding mold.

4. Overloading mold main components.

5. Metal extrusion die die set.

3. Feature:

1. Pure steel vacuum degassing refining process for polishing or etch processing plastic mold

2. Pre-hardened state of supply, without heat treatment can be used directly in the mold, shorten the construction period.

3. By forging rolling processing, compact structure, 100% ultrasonic testing, non-porous, needle defects.

4. For the production of plastic mold and die casting low melting point metal mold material.

5. This steel has good machinability and mirror polishing properties.

6. Hardness:28-32HRC

7. Good dimensional stability

8. With long service life,Mold die life up to 50W times

4. Chemical composition (%)

| C | Si | Mn | P | S | Cr | Mo |

| 0.28-0.40 | 0.20-0.80 | 0.60-1.00 | ≤0.030 | ≤0.030 | 1.40-2.00 | 0.3-0.55 |

5. Characteristic of 1.2311 steel flat bar:

1. Vacuum degassing refining processing steel purity, suitable for polishing or etch processing plastic mold.

2. In pre-harden state delivery, no need in heat ttreatment can be directly used for mould processing, shorten the construction.

3. After heat treatment machining and polishing performance is good, the nitriding treatment, can be suitable for chrome plating surface treatment, such as material is qualitative hardness is uniform (400mm thick), good toughness and good machining performance.

Our company have introduced large-sized vertical saw machines, horizontal saw machines, milling machines, grinding machines and other advance equipments, we can export our products by wholesales and retail sales, whole plate or strip is available. All our products can meet the standards of DIN, AISI, JIS and GB, all the material should be inspected the ultrasonic, hardness and others strict inspection process before the shipment!

We can provide below service:

A. Steel plates: Cutting by bandsaw machine, milling, heat treatment, etc

B. Round bars: Cutting by bandsaw machine, peeling, grinding and turned, heat treatment, etc

6. Payment term: T/T or L/C

7. Delivery time:

1) For abundant stock, 7-15 days.

2) For customized products, 15-30 days.

Warehous

Processing

Strict Quality Control