AISI L6 /DIN 1.2714 /JIS Skt4 Tool Steel Bar

Guangzhou Kingmetal Steel Industry Co., Ltd.- Type:Alloy Steel Bar

- Standard:AISI, ASTM, GB, JIS, DIN, BS

- Technique:Forged

- Application:Structural Steel Bar, Tool Steel Bar

- Surface Treatment:Polished

- Alloy:Alloy

Base Info

- Model NO.:KM-143

- Special Use:Mold Steel, Cold Heading Steel

- Size:130mm-1000mm (Optional)

- Length:2m,3m,5.8m, 6m, 8m or as Required.

- Delivery Time:7-30 Days

- Loading Port:Shanghai

- MOQ:3 Tons

- Certificate:ISO, BV, SGS, Mill Test Certificate

- Packaging Detail:Standard Sea-Worthy Package

- Surface:Bright, Black

- Price Term:Ex-Work, Fob, CFR, CIF, etc.

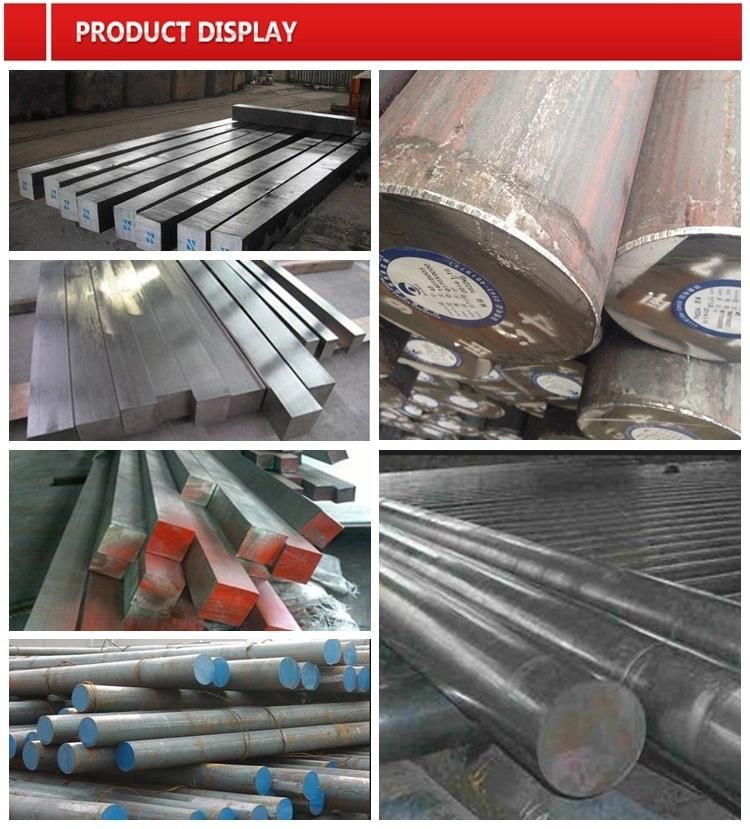

- Specifications:Flat Bar, Round Bar, Angle Bar, Square Bar

- Transport Package:Standard Sea-Worthy Package

- Specification:130mm-1000mm (optional)

- Trademark:Kingmetal

- Origin:China (Mainland)

- Production Capacity:800tons,Month

Description

Round

Φ16-Φ350

Hot Rolled

Φ90-Φ1000

Hot Forged

Flat/Square/Block

Hot Forged

Remark:Tolerance can be customized as per requests

2.Chemical Composition

DIN EN ISO 4957

0.50-0.60

0.1-0.4

0.60-0.90

0.03

0.02

0.8-1.2

1.50-1.8

0.35-0.55

0.05-0.15

3.Physical Property

205. Mechanical Property

Quenching at

860 °C in oil

Quenching at

860 °C in air

6.Forging

Heat the temperature to 750 oC - 800 oC ,hold for suitable time,then heat the temperature up to 1050oC,hold enough time for the steel to be thoroughly heated.Don't forge below 850oC.AISI L6 steel should be cooled as slowly as possible in the furnance.Annealing is strongly recommended after forged.

7.Annealing

Annealing must be performed after hot working and before re-hardening.Heat the temperature to740- 760°C with a rate not exceeding 220°C per hour , and hold at temperature for 1 hour per inch (25.4mm) of maximum thickness; 2 hours minimum. Then cool slowly with the furnace at a rate not exceeding 20°C per hour to 500°C. Continue cooling to ambient temperature in the furnace or in air. The resultant hardness should be a maximum of 235 HBW.

8.Hardening

Prheat uniformly to the temperature 650-700°C ,Quench in air with hardening temperature 870-900°C,or quench in oil with with hardening temperature 830-870°C,tempering should be followed as soon as possible.

9.Tempering

Heat uniformly to the required temperature allowing a soaking time of two hours per 25mm of ruling section. Withdraw from the furnace and allow to cool in air. A second tempering is highly recommended, the tool being allowed to cool to room temperature between tempers.

| Temperature ,°C | 200 | 250 | 300 | 400 | 500 |

| Hardness , HRC | 55 | 54 | 53 | 49 | 45 |

10.Application

AISI L6 is highly recommendable for Close Die Forgings due to its characteristics of high wear-resistance, extra toughness , high hardness which is achieved with Cr-Ni-Mo-V high graded alloys.

Typical applications includes Arbors, blanking dies, clutch parts, forming dies,disc saws, drift pins, brake dies, hand stamps,hubs, lead and feed screws, machine parts,punches, pawls, pinions, shear blades, spindles,spring collets, swages and etc.