Polished Steel Round Bar 1.7218 Scm430 25crmo4 4130 30CrMo4

Shandong Zayi Steel Co., Ltd- Standard:DIN, JIS, AISI, ASTM, GB, BS

- Technics:Forged

- Application:Tool Steel Bar

- Surface:Polished

- Alloy:Alloy

- Special Use:High-strength Steel Plate, Wear Resistant Steel, Silicon Steel, Cold Heading Steel, Free Cutting Steel, Mold Steel

Base Info

- Model NO.:Steel Round Bar 1.7218 Scm430 25crmo4 4130 30crmo4

- Heat Treatment:Annealed

- Length:3000-5800mm

- Non-Metallic Inclusiton:ASTM E45

- Grain Size:ASTM E112

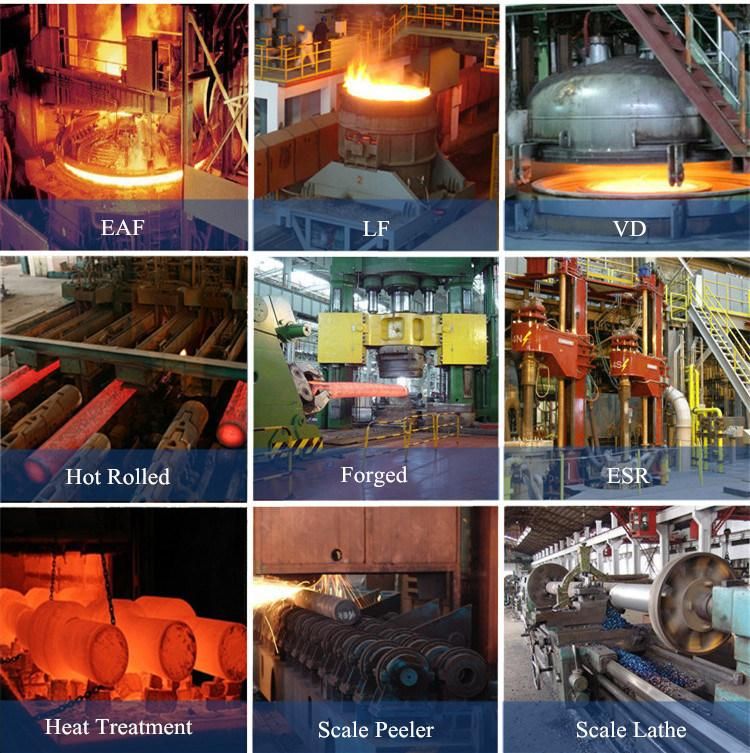

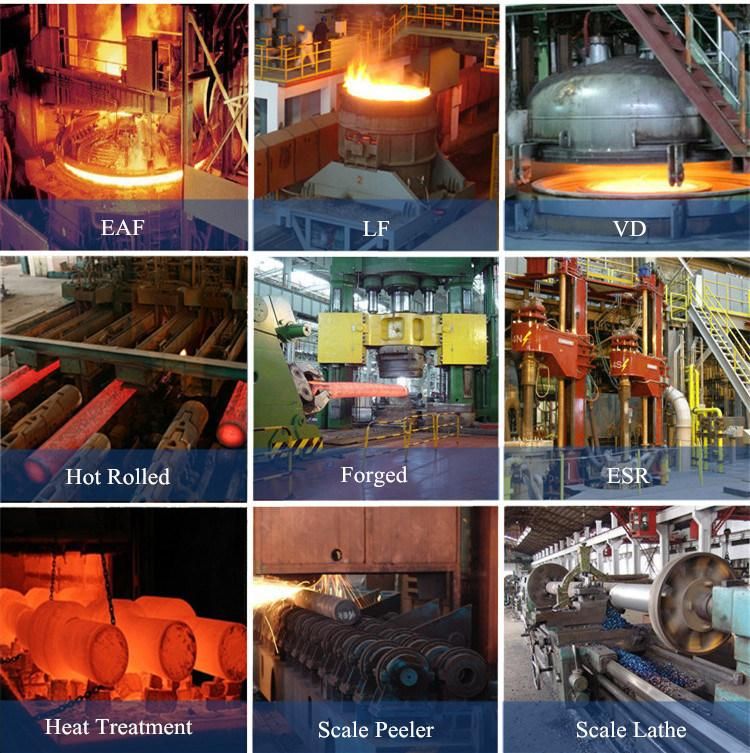

- Process:Eaf+Lf+Vd+Forged+Heat Treatment(Optional)

- Technology:Hot Rolled, Forged, Cold Drawn

- Usage:Automotive, Aerospace, Power Generation, Oil & Gas

- Ex-Stock:Yes

- Service:24 Hours on Line

- Other Type:Engineering Steel, Cold Work Tool Steel

- Test:Ensile Strength, Yield Strength, Elongation,

- Other Type 1:Engineering Steel, Cold Work Tool Steel

- Other Type 2:Hot Work Tool Steel, Plastic Mold Steel

- Other Type 3:Spring Steel, High Speed Steel, Stainless Steel

- Other Type 4:Mold Steel, Free Cutting Steel, Cold Heading Steel

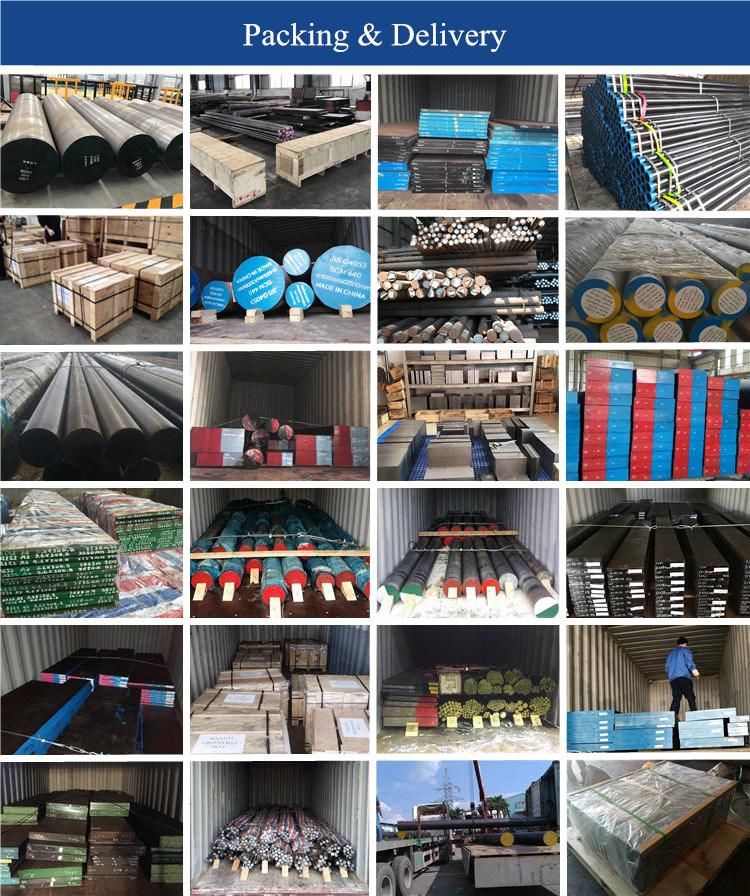

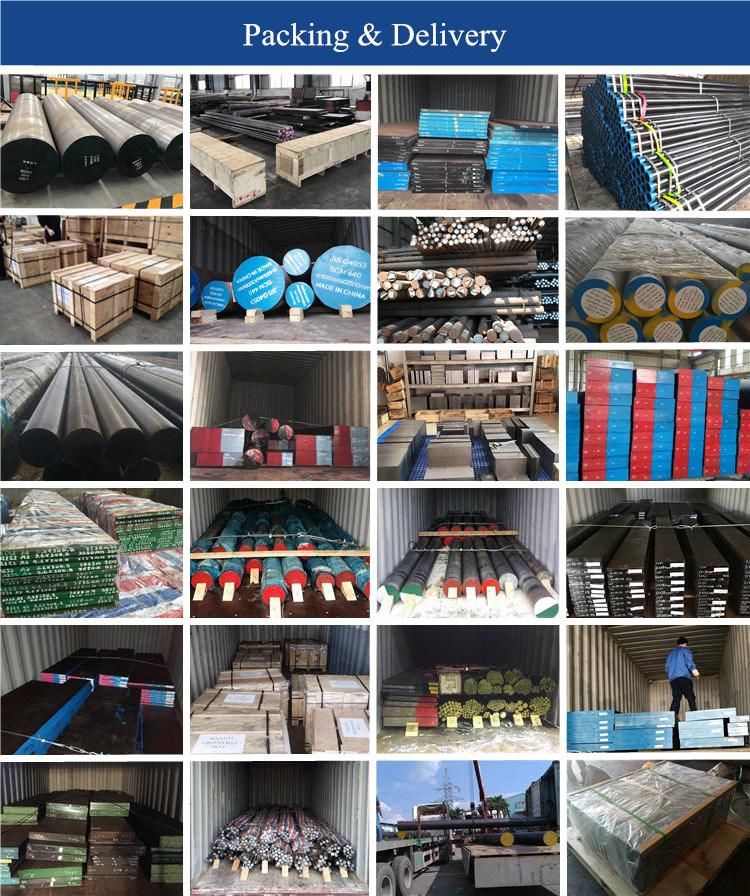

- Transport Package:Seaworthy Package

- Specification:DIA 60-600

- Trademark:zayi

- Origin:China

- HS Code:72284000

- Production Capacity:48000tons,Month

Description

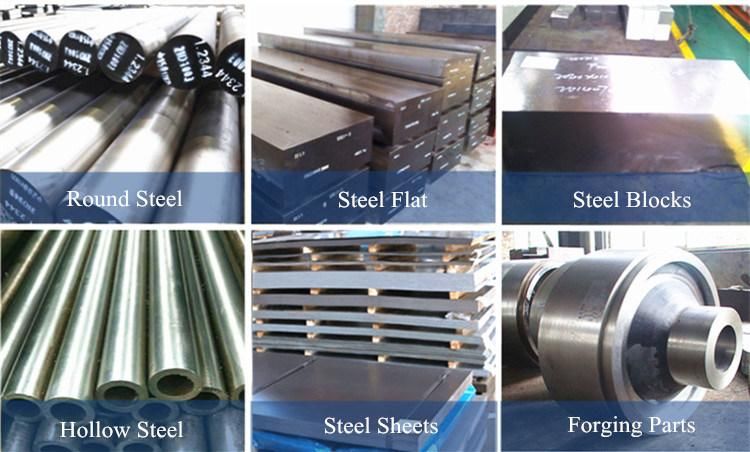

SizeRound Dia 6-1200mm Plate/Flat/Block Thickness

6mm-500mm Width

20mm-1000mm Heat treatment Normalized ; Annealed ; Quenched ; Tempered Surface condition Black; Peeled; Polished; Machined; Grinded; Turned; Milled Delivery condition Forged; Hot rolled; Cold drawn Test Tensile strength, Yield strength, elongation, area of reduction, impact value, hardness, grain size, ultrasonic test, US inspection, magnetic particle testing, etc. Payment terms T/T;L/C;/Money gram/ Paypal Trade terms FOB; CIF; CNF Delivery time 20-25 days Application D2 used for Blanking Dies, Forming Dies, Coining Dies, Slitting Cutters, Heading Tools, Long Punches, Forming Rolls, Edging Rolls, Master Tools, Beading Rolls, Intricate Punches, Extrusion Dies, Drawing Dies, Lamination Dies, Thread Rolling Dies, Shear Blades, Burnishing Tools, Gauges, Knurls, Wear Parts.

6: Delivery condition

For hot forged bar, usually the delivery condition is hot forged, annealed rough turned/Black surface.

For hot rolled bar, usually the delivery condition is hot rolled, annealed, Black surface.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

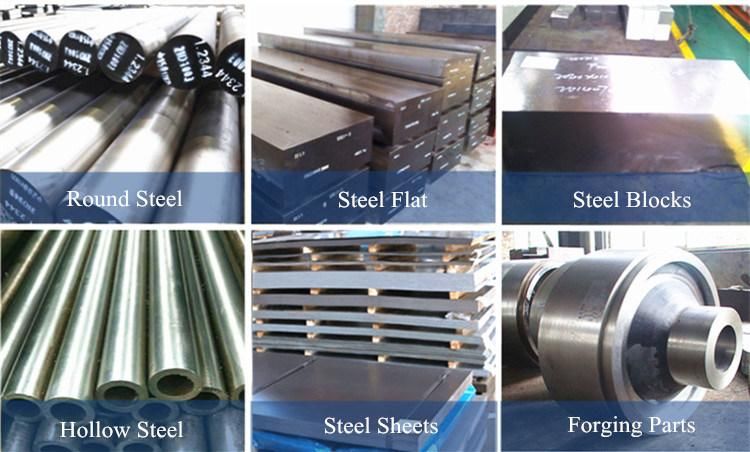

Shandong Zayi has the capacity to forge round steel, steel flat, square steel, module, shaft and roller, etc. The main specifications of the products include Φ80-1000mm forging materials and 80-1200mm square billets and which the maximum piece weight can reach 50T.

We were already engaged in exporting steel for 11 years, could supply a great variety of hot forged, hot rolled and cold drawn Steels, including engineering steel, cold work tool steel, hot work tool steel, plastic mold steel, spring steel, high speed steel, stainless steel etc., besides Shandong Zayi also has their own heating treatment shop and machining shop to provide heating and cutting service.

Since 2008 year, Shandong Zayi has the right to export all FORGED STEEL .The forged products are used in Automotive, Aerospace, Power Generation, Oil & Gas, Transportation and Industrial. We already set up the warehouse in Wuxi and Dongguan city, more than 20000 tons ex-stock could be supplied with kinds of size.

Shandong Zayi is the professional one-stop steel manufacturer, stockist and exporter in China, our customers spread all over the world, include West Europe, North America, South America, Asia, Middle Asia, Africa, Australia, etc.

The company owns advanced special steel smelting facilities and forging processing equipments, the main steel-making equipment include 2 sets of 50t ultra-high power electric arc furnaces,2 sets of 60t LF refining furnaces,1 set of 60t vacuum degassing refining furnace and 4 sets of 1-20t electroslag re-melting furnaces.

The main forging equipments mainly include:3 sets of 5t electro-hydraulic hammers, 1 set of high-speed forging units of 800t,1600t,2000t and 4500t respectively.

6mm-500mm

20mm-1000mm

6: Delivery condition

For hot forged bar, usually the delivery condition is hot forged, annealed rough turned/Black surface.

For hot rolled bar, usually the delivery condition is hot rolled, annealed, Black surface.

For hot forged plate, usually the delivery condition is hot forged, annealed, milled surface

For hot rolled plate, usually the delivery condition is hot rolled, annealed, black surface.

Shandong Zayi has the capacity to forge round steel, steel flat, square steel, module, shaft and roller, etc. The main specifications of the products include Φ80-1000mm forging materials and 80-1200mm square billets and which the maximum piece weight can reach 50T.

We were already engaged in exporting steel for 11 years, could supply a great variety of hot forged, hot rolled and cold drawn Steels, including engineering steel, cold work tool steel, hot work tool steel, plastic mold steel, spring steel, high speed steel, stainless steel etc., besides Shandong Zayi also has their own heating treatment shop and machining shop to provide heating and cutting service.

Since 2008 year, Shandong Zayi has the right to export all FORGED STEEL .The forged products are used in Automotive, Aerospace, Power Generation, Oil & Gas, Transportation and Industrial. We already set up the warehouse in Wuxi and Dongguan city, more than 20000 tons ex-stock could be supplied with kinds of size.

Shandong Zayi is the professional one-stop steel manufacturer, stockist and exporter in China, our customers spread all over the world, include West Europe, North America, South America, Asia, Middle Asia, Africa, Australia, etc.

The company owns advanced special steel smelting facilities and forging processing equipments, the main steel-making equipment include 2 sets of 50t ultra-high power electric arc furnaces,2 sets of 60t LF refining furnaces,1 set of 60t vacuum degassing refining furnace and 4 sets of 1-20t electroslag re-melting furnaces.

The main forging equipments mainly include:3 sets of 5t electro-hydraulic hammers, 1 set of high-speed forging units of 800t,1600t,2000t and 4500t respectively.