Guangzhou Sailong Additive Manufacturing Co., Ltd.

Guangzhou Sailong Additive Manufacturing Co., Ltd., founded in 2018, is a national high-tech enterprise and is a high-tech enterprise LED by the core members of the technical team. The company′s enterpreneurial team consist of seven Doctors including Professor Tang Huiping who is the director of the State Key Laboratory of Porous Metal Materials, and Wang Qiangbing, deputy director of the State Key Laboratory of Porous Metal Materials.

Professor Tang Huiping is the chairman of the company, adn Dr. Wang Qiangbing is the general manager of the company. The company has more than 90% of the postgraduates. Theestablishment of the company is based on the latest research results in 3D printing, which filled the gap of manufacturing technology of powder bed electron beam additive manufacturing in Guangdong, Hongkong and Mecao Great Bay Area. Our goal is to create an international first-class company and a well-known brand in area of metal additive manufacturing.

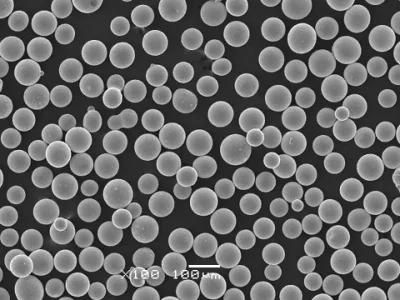

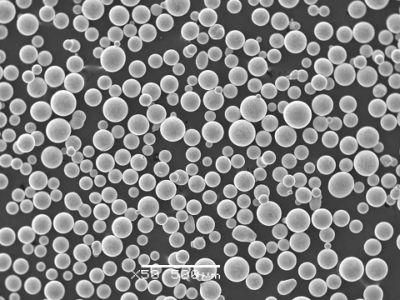

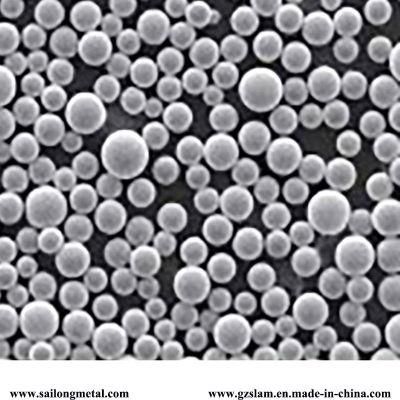

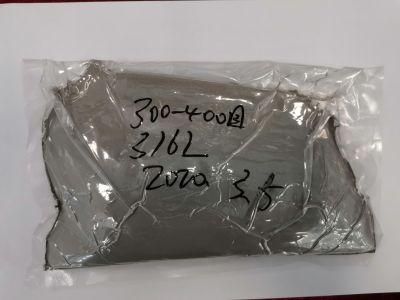

Core businesses focus on developing (1) metal powders and powder metallurgy products; (2)Al, Steel, Copper, Ti, W, Tungsten, Nickel etc metal material; (3) porous metal foam; (4)3D printing medical implants; (5)Disposable Medical Supplies. It is mainly used in industry, aviation, military, automobile, marine, medical, decoration and other fields. Sailong enjoys a high reputation worldwide.

Business scope:

Manufacturing of special equipment for refining and chemical production; Manufacturing of non-ferrous metal alloys; Manufacturing of 3D scanning and printing equipment; Sales of 3D scanning and printing equipment; Reseacrh and development of 3D scanning and printing equipment; Import and export of goods(excluding special-controlled commodities); Import and export of technology; Prosthetics, artificilal organs and implanted (interventional) manufacturing facturing apparatus.

Development path:

In 2001, the team won the "863" program to research the titanium alloy powder of 3D printing.

In 2007, cooperated with Tsinghua University to develop SEBM 250 electron beam 3D printer with independent intellectual property rights.

During 2009 to 2010, conquered the 3D printing technology of titanium alloy and superalloy, and the products were successfully applied in aerospace, clinical medicine and other fields.

During 2015 to 2016, developed PREP equipment; Developed the first commercial SEBM equipment in China.

In 2018, established Guangzhou Sailing Additive manufacturing Co., Ltd.

Professor Tang Huiping is the chairman of the company, adn Dr. Wang Qiangbing is the general manager of the company. The company has more than 90% of the postgraduates. Theestablishment of the company is based on the latest research results in 3D printing, which filled the gap of manufacturing technology of powder bed electron beam additive manufacturing in Guangdong, Hongkong and Mecao Great Bay Area. Our goal is to create an international first-class company and a well-known brand in area of metal additive manufacturing.

Core businesses focus on developing (1) metal powders and powder metallurgy products; (2)Al, Steel, Copper, Ti, W, Tungsten, Nickel etc metal material; (3) porous metal foam; (4)3D printing medical implants; (5)Disposable Medical Supplies. It is mainly used in industry, aviation, military, automobile, marine, medical, decoration and other fields. Sailong enjoys a high reputation worldwide.

Business scope:

Manufacturing of special equipment for refining and chemical production; Manufacturing of non-ferrous metal alloys; Manufacturing of 3D scanning and printing equipment; Sales of 3D scanning and printing equipment; Reseacrh and development of 3D scanning and printing equipment; Import and export of goods(excluding special-controlled commodities); Import and export of technology; Prosthetics, artificilal organs and implanted (interventional) manufacturing facturing apparatus.

Development path:

In 2001, the team won the "863" program to research the titanium alloy powder of 3D printing.

In 2007, cooperated with Tsinghua University to develop SEBM 250 electron beam 3D printer with independent intellectual property rights.

During 2009 to 2010, conquered the 3D printing technology of titanium alloy and superalloy, and the products were successfully applied in aerospace, clinical medicine and other fields.

During 2015 to 2016, developed PREP equipment; Developed the first commercial SEBM equipment in China.

In 2018, established Guangzhou Sailing Additive manufacturing Co., Ltd.

Product List